-

木材陶瓷是由日本青森工业试验场的冈部敏弘和斋藤幸司采用木材或其他木质材料,在热固性树脂中浸渍后真空炭化而成的一种新型碳素材料[1-2]。木材陶瓷作为一种新型生物质陶瓷材料,具有多孔、导电、自润滑等特性,在摩擦、过滤、吸附、电磁屏蔽、房暖等领域有广阔的应用前景[3]。近年来,以木材为原料制备木材陶瓷的研究颇多且比较深入,而以竹材原料研制竹材陶瓷的报道较少。但中国木材资源较贫乏,而竹林面积、竹材产量却居世界之首[4]。故以竹材为原料研制竹材陶瓷,对于节约木材资源、保护生态环境等具有十分重要的意义。虽然中国竹材加工利用水平居世界领先地位,是大量的竹材加工剩余物——竹碎料,除部分用作锅炉辅助燃料、烧制竹炭等以外,多数没能开发利用,资源浪费较严重。若用竹碎料制造竹材陶瓷,就为其加工利用提供了新的途径。目前,有少数学者以竹粉、竹片、竹炭等为原料,进行了竹材陶瓷制造工艺、性能等研究[5-9],但未见以竹碎料为原料研制竹材陶瓷的报道。因此,本研究在前期研究的基础上[10],以竹地板生产中竹片精刨加工的剩余物-精刨竹碎料为原料研制竹材陶瓷,主要探讨烧结工艺对竹材陶瓷性能和结构等的影响规律,可为竹碎料的高效加工利用提供理论参考。

-

精刨竹碎料:竹地板生产中竹片精刨加工的剩余物,经筛选去除粉尘、泥砂、过大竹碎料后,干燥到含水率4%~6%。胶黏剂:水溶性酚醛树脂胶,固体含量为48%。

-

按酚醛树脂施加量40%对精刨竹碎料进行拌胶,经铺装、热压后制得密度为0.88 g·cm-3的竹碎料板,将它锯割成100 mm × 50 mm × 12 mm的试样。参照现有国内外文献中有关木竹材陶瓷的烧结工艺,根据竹碎料板的特点进行初步试验后,确定了如下烧结工艺:将试样放入管式电阻炉中,在氮气保护下,分别在600,800,1 000和1 200 ℃的烧结温度下烧制竹材陶瓷;烧结时的程序控制工艺为:先以5 ℃·min-1的升温速度升到150 ℃,保温20 min;之后以3 ℃·min-1的升温速度升到600 ℃(800,1 000,1 200 ℃),再保温烧结炭化3 h,然后以5 ℃·min-1的速度降温到200 ℃,最后随炉冷却,制得竹材陶瓷。

-

分别检测在600,800,1 000和1 200 ℃烧结温度下制得的竹材陶瓷的尺寸收缩率、密度减少率、炭得率、静曲强度和弹性模量,研究烧结工艺对竹材陶瓷性能的影响。其中,尺寸收缩率按照试件烧结前后的尺寸之差与烧结前尺寸的百分比计算,密度减少率按照试件烧结前后的密度之差与烧结前密度的百分比计算,炭得率按试件烧结后的质量与烧结前的质量的百分比计算,静曲强度和弹性模量采用三点弯曲方法在微机控制的万能力学试验机上测试。

-

采用日本岛津公司的XRD6000型X射线粉末衍射仪,分析不同烧结温度下竹材陶瓷的物相组成。X光管为铜靶,管电压为40 kV,管电流为30 mA,采用2θ/θ联动扫描,样品扫描范围5°~60°(2θ)。

-

采用日本岛津公司的SS-550型扫描电子显微镜(SEM),观察竹材陶瓷的微观结构。

-

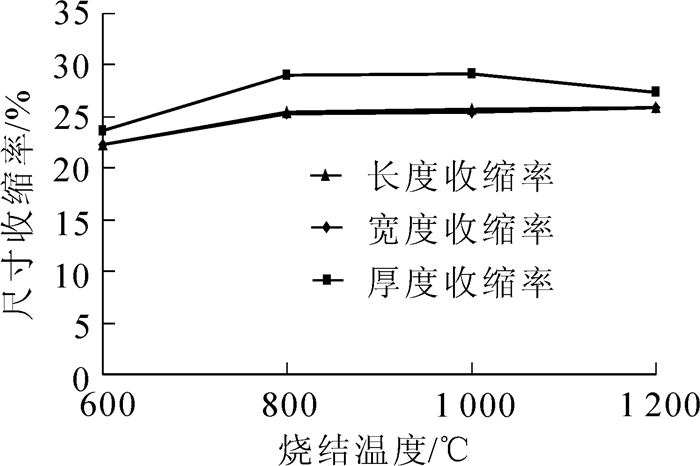

由图 1可知:烧结温度不同竹材陶瓷的尺寸收缩率不同。当烧结温度为600~800 ℃时,竹材陶瓷的尺寸收缩率随着烧结温度的升高而较快增加;当烧结温度为800~1 000 ℃时,竹材陶瓷的尺寸收缩率大小接近、曲线变化趋于平稳;当烧结温度超过1 000 ℃时,竹材陶瓷尺寸收缩率的变化速度趋缓。其中,竹材陶瓷的长度收缩率、宽度收缩率随着烧结温度的升高而增大,而厚度收缩率在烧结温度600~1 000 ℃范围内随着烧结温度的升高而增加,当烧结温度超过1 000 ℃时却随着烧结温度的升高而降低;厚度收缩率大于长度收缩率和宽度收缩率,长度收缩率和宽度收缩率大小接近。图 1显示:不论哪种烧结温度下竹材陶瓷的尺寸收缩率都超过20%。可见,竹材陶瓷制备时的烧结温度对其尺寸收缩率有较大影响。这主要是因为在密封高温条件下烧结,竹碎料和酚醛树脂均发生了系列热分解,致使竹材陶瓷在长度、宽度和厚度方向的尺寸减小较多;然而,竹材陶瓷的尺寸收缩率在烧结温度800~1 000 ℃范围内却趋于平稳。因此,可认为竹材陶瓷的较佳烧结温度范围为800~1 000 ℃。

-

从图 2可得知:烧结温度在600~1 000 ℃范围内,竹材陶瓷的密度减少率随着烧结温度的升高而逐渐降低,其中烧结温度为600~800 ℃的密度减少率的变化速度较快,800~1 000 ℃的密度减少率大小接近、曲线变化较平稳;烧结温度超过1 000 ℃时密度减少率又随着烧结温度的升高而缓慢增加。究其主要原因可能是:竹材陶瓷的质量损失、体积收缩率都随着烧结温度的升高而逐渐增大,其中烧结温度为600~800 ℃时增加较快,大于1 000 ℃时增加趋缓,800~1 000 ℃时变化较平稳;而在相同烧结温度下质量损失率变化速度却快于体积收缩率。由图 3显示:随着烧结温度的升高竹材陶瓷的炭得率逐渐降低,其中烧结温度在600~800 ℃范围内的炭得率随着温度的升高较快降低,超过800 ℃时的炭得率降低速度趋缓,1 000℃的炭得率为800 ℃时的98.4%,而1 200 ℃时的炭得率为1 000 ℃时的97.4%。可见,当烧结温度大于800 ℃时,烧结温度对炭得率的影响就不大了。由于竹材陶瓷由竹碎料与酚醛树脂复合制得,故竹碎料板在高温炭化过程中的热解实际上由竹碎料的热解与酚醛树脂的热解共同组成。竹材与木材一样,其主要化学成分纤维素、半纤维素和木质素总的含量达90%以上,因而可以认为竹碎料的热解规律与木粉基本相同。而导致图 3所示炭得率的变化规律的主要原因是:在氮气保护下,竹碎料在240~400 ℃范围内热解最激烈,在800 ℃之前基本分解完全;而酚醛树脂在500~600 ℃范围内热解最激烈,在800 ℃之后热解才结束[11-12],而竹材陶瓷中竹碎料的量却大于酚醛树脂。因而烧结温度800 ℃前炭得率降低速度较快,之后降低速度变慢。

-

不同烧结温度制造的竹材陶瓷的静曲强度和弹性模量,分别见图 4和图 5。从图 4和图 5可以看出:随着烧结温度的升高,竹材陶瓷的静曲强度和弹性模量逐渐增加,但它们均不高。其中,烧结温度为600 ℃时的静曲强度和弹性模量最低,烧结温度1 200 ℃时的炭得率的静曲强度和弹性模量最高;烧结温度800 ℃和1 000 ℃制备的竹材陶瓷的静曲强度和弹性模量大小接近,曲线变化较平稳。这是因为在炭化过程中,碳的芳环结构形成始于400~500 ℃,随着炭化温度的升高,碳多环结构中碳原子数增多,石墨微晶长大且排列更加规则;特别是酚醛树脂生成的玻璃碳和竹碎料生成的无定形碳在高温度下会生长在一起,其界面逐渐消失,2种碳之间的结合强度增加[11],从而导致竹碎料板竹材陶瓷的静曲强度和弹性模量增加。此外,竹碎料板高温烧结成竹材陶瓷后,4种烧结温度所制竹材陶瓷的平均密度为0.67 g·cm-3,仅有烧结前密度0.88 g·cm-3的76.1%,加之竹材陶瓷中存在大量力学强度较低的无定形碳。因此,竹材陶瓷的静曲强度和弹性模量均不高。

-

从图 6竹材陶瓷的X射线衍射(XRD)图谱可知:竹材陶瓷的衍射峰都是宽峰,说明竹材陶瓷没有出现完整的晶形结构,是一种典型的无定形碳。因为竹碎料板高温烧结炭化后,竹碎料转化为软质无定型碳,而酚醛树转化为硬质玻璃碳,两者本质上都属于碳的无定形结构,是不具有石墨结构的非结晶性物质[13-14]。因而在烧结温度600~1 200 ℃范围内制得的竹材陶瓷并非是完全石墨化的碳,而是部分石墨化的无定型碳。图 6显示:随着烧结温度的升高,(002)衍射峰逐渐变窄变强,这表明竹材陶瓷中石墨微晶的含量增加,微晶中层与层之间的排列更趋于规整[15],且微晶的含碳量增加。因而随炭化温度的升高竹材陶瓷的石墨化程度逐渐增强。对比600,800,1 000和1 200 ℃烧结温度的XRD曲线可知,曲线的变化规律基本相同,只有强度差异,说明在烧结温度600~1 200 ℃内制得的竹材陶瓷的晶体构造基本相同,但结晶度发生了变化。

-

由不同烧结温度制造的竹材陶瓷的扫描电子显微镜(SEM)照片(图 7)可知:在不同烧结温度下制备的竹材陶瓷基本保持了竹材原有的微观结构形态,竹材陶瓷中竹材的薄壁细胞、导管等的微观结构形态依然清晰可见。但竹材细胞断面的孔隙部分或全部被须状、颗粒状、片状、层状等不同形态的物质中所填充、覆盖。这些填充、覆盖物质可能大部分是酚醛树脂经高温炭化后转化成的硬质玻璃碳。这是因为竹碎料板是由酚醛树脂胶黏剂与精刨竹碎料经过拌胶、铺装、热压等工序制得,在拌胶过程中液状的酚醛树脂胶黏剂分布于竹碎料之间,有的甚至渗透到竹材细胞腔及细胞间隙中,同时在热压过程中酚醛树脂胶黏剂进一步流展、渗透,待其固化后就留于竹材细胞腔及细胞间隙中,经高温炭化后酚醛树脂就转化成硬质玻璃碳,在微观上表现为填充、覆盖于竹材细胞的孔隙中,从而强化竹材细胞。从图 7还知:随着烧结温度的升高,竹材细胞中须状、颗粒状物质越少,而片状、层状物质却越多,竹材细胞的孔隙被填充、覆盖也越多,而且竹材细胞的微观结构形态也不断变化,细胞之间的分界逐渐变得模糊有的甚至消失。这进一步证实了随着烧结温度的升高,竹材陶瓷中石墨微晶的含量增加,微晶的含碳量增加,微晶中层与层之间的排列更趋于规整有序。

-

①烧结温度对竹材陶瓷的尺寸收缩率有较大影响。竹材陶瓷的尺寸收缩率随着烧结温度的变化而变化,其中厚度收缩率大于长度收缩率和宽度收缩率,长度收缩率和宽度收缩率大小接近。②烧结工艺对竹材陶瓷的密度减少率、炭得率、静曲强度和弹性模量均有影响。密度减少率在600~1 000 ℃范围内随着烧结温度的升高逐渐降低,烧结温度超过1 000 ℃后却逐渐增加;竹材陶瓷的炭得率随着烧结温度的升高逐渐降低,而静曲强度和弹性模量却随着烧结温度的升高逐渐增加。③竹材陶瓷是一种典型的无定形碳。随着烧结温度的升高,竹材陶瓷的石墨化程度逐渐增强。④存在于竹材细胞之间、细胞腔及细胞间隙中的酚醛树脂,经高温炭化后形成的硬质玻璃碳对竹材细胞有填充、强化作用。⑤烧结温度为800~1 000 ℃时,可制得尺寸收缩率、炭得率、力学强度等性能较稳定的竹材陶瓷。

Sintering technology of bambooceramics prepared from bamboo particles with phenol-formaldehyde resin

-

摘要: 以精刨竹碎料和酚醛树脂为原料,采用高温真空炭化烧结工艺制备了竹材陶瓷,研究了烧结工艺对竹材陶瓷性能、物相组成和微观结构等的影响。结果表明:①烧结温度对竹材陶瓷的尺寸收缩率有较大影响,当烧结温度为600~1 200 ℃时,竹材陶瓷的尺寸收缩率大于20%范围内;②竹材陶瓷的密度减少率在600~1 000 ℃范围内,随着烧结温度的升高逐渐降低,在1 000~1 200 ℃范围内,随着烧结温度的升高逐渐增加;③随着烧结温度的升高,竹材陶瓷的炭得率降低、静曲强度和弹性模量升高、石墨化程度逐渐增强;④酚醛树脂经高温炭化后形成的硬质玻璃碳对竹材细胞起填充、强化作用;⑤竹材陶瓷的较佳烧结温度范围为800~1 000 ℃。图7参15Abstract: To determine the effects of sintering technology on microstructure, phase identification, and properties of bambooceramics, a new bambooceramics was prepared by carbonizing in a vacuum at high temperatures using phenol-formaldehyde resin and precision-shaved bamboo particles as raw materials. Results showed that (1) sintering temperatures had a strong influence on the dimension shrinkage ratio of the bambooceramic and was greater than 20% when the sintering temperature was 600-1 200 ℃. Also, (2) the density reduction ratio of bambooceramics gradually decreased with an increase in the sintering temperature from 600 ℃ to 1 000 ℃, then gradually increased from 1 000 ℃ to 1 200 ℃. Next, (3) with an increase in sintering temperature, the carbon yield ratio of bambooceramics decreased, its modulus of rupture (MOR) and modulus of elasticity (MOE) increased, and its degree of graphitization gradually increased. Finally, (4) the hard glass carbon from phenol resin formed by high temperature carbonization filled and reinforced the bamboo cell, thereby improving (5) the sintering temperature range of bambooceramics to 800-1 000 ℃.[Ch, 7 fig. 15 ref.]

-

-

[1] HIROSE T, ZHAO Binyuan, OKABE T, et al. Effect of carbonization temperature on the basic properties of wood ceramics made from carbonized bamboo fiber and liquefied wood [J]. J Mater Sci, 2002, 37(16): 3453-3458. [2] 马荣, 乔冠军, 金志浩. 木材陶瓷[J]. 兵器材料科学与工程, 1998, 21(6): 45-48. MA Rong, QIAO Guanjun, JIN Zhihao. Woodceramics [J]. Ordnance Mater Sci Eng, 1998, 21(6): 45-48. [3] 乔冠军, 金志浩. 用木材制备生物结构陶瓷[J]. 材料导报, 2003, 17(4): 66-69. QIAO Guanjun, JIN Zhihao. Biostructure ceramics derived from wood [J]. Mater Rev, 2003, 17(4): 66-69. [4] 王凡非, 王文衡. 我国竹材人造板生产现状与问题初探[J]. 中国人造板, 2007, 14(12): 1-4. WANG Fanfei, WANG Wenheng. The status quo and problems of bamboo-based panels production in China [J]. China Wood-Based Panels, 2007, 14(12): 1-4. [5] 江泽慧, 任海青, 费本华, 等. 竹炭及SiC陶瓷材料的结构与性能[J]. 新型炭材料, 2006, 21(1): 1-8. JIANG Zehui, REN Haiqing, FEI Benhua, et al. Them icro-structure and properties of charcoal and SiC ceramics derived from bamboo [J]. New Carbon Mater, 2006, 21(1): 1-8. [6] 周蔚虹, 喻云水, 曹宏彰, 等. 竹粉/呋喃树脂制备木陶瓷的研究[J]. 硅酸盐通报, 2010, 29(6): 11380-1383, 1388. ZHOU Weihong, YU Yunshui, CAO Hongzhang, et al. Research on woodcernics prepared from bamboo powder-furane resin composite [J]. Bull Chin Ceram Soc, 2010, 29(6): 11380-1383, 1388. [7] 孙德林, 余先纯, 王荣, 等. 烧结温度对环氧树脂/竹基木陶瓷性能的影响[J]. 材料热处理学报, 2011, 32(9): 18-22. SUN Delin, YU Xianchun, WANC Rong, et al. Effects of sintering temperature on performance of epoxy resin/bamboo woodceramics [J]. Trans Mater Heat Treat, 2011, 32(9): 18-22. [8] 田根林, 余雁, 张求慧, 等. 竹基SiC/C生物陶瓷的制备和性能[J]. 林业科学, 2012, 48(1): 138-142. TIAN Genlin, YU Yang, ZHANG Qiuhui, et al. Fabrication and performance of bamboo-based SiC/C biological ceramics [J]. Sci Silv Sin, 2012, 48(1): 138-142. [9] 程大莉, 蒋身学. 不同密度的竹陶瓷的性能研究[J]. 林业科技开发, 2013, 27(2): 77-80. CHENG Dali, JIANG Shenxue. Properties of bamboo ceramics with different densities[J]. China For Sci Technol, 2013, 27(2): 77-80. [10] DU Chungui, LI Ren, ZHANG Weigang, et al. Study on bamboo particleboard bambooceramics-bamboo particletypes and resin content influence on properties of bamboo particleboard [J]. Appl Mech Mater, 2014, 584/586: 1461-1464. [11] 钱军民, 王继平, 金志浩. 由椴木木粉和酚醛树脂制备木材陶瓷的研究[J]. 无机材料学报, 2004, 19(2): 335-341. QIAN Junmin, WANG Jiping, JIN Zhihao. Woodceramics prepared from basswood powder and phenolic resin[J]. J Inorg Mater, 2004, 19(2): 335-341. [12] 陶毓博, 李淑君, 李鹏, 等. 酚醛树脂用量对木陶瓷性能的影响[J]. 材料热处理学报, 2010, 31(2): 26-29. TAO Yubo, LI Shujun, LI Peng, et al. Effect of phenolic resin proportion on properties of woodceramics [J]. Trans Mater Heat Treat, 2010, 31(2): 26-29. [13] 钱军民, 金志浩, 王继平. 酚醛树脂/木粉复合材料制备木材陶瓷结构变化过程研究[J]. 复合材料学报, 2004, 21(4): 18-23. QIAN Junmin, JIN Zhihao, WANG Jiping. Study on structural changes during preparing woodceramics from phenolic resin /basswood powder composite [J]. Acta Mater Compos Sin, 2004, 21(4): 18-23. [14] TZENG S S, CHR Y G. Evolution of microstructure and properties of phenolic resin-based carbon/carbon composites during pyrolysis [J]. Mater Chem Phys, 2002, 73(2/3): 162-169. [15] 涂建华, 张利波, 彭金辉, 等. 炭化温度对木质陶瓷性能和结构的影响[J]. 材料热处理学报, 2006, 27(3): 10-15, 21. TU Jianhua, ZHANG Libo, PENG Jinhui, et al. Effect of carbonization temperature on the properties and structure of woodceramics from carbonizing tobacco stems phenolic resin composites[J]. Trans Mater Heat Treat, 2006, 27(3): 10-15, 21. -

-

链接本文:

https://zlxb.zafu.edu.cn/article/doi/10.11833/j.issn.2095-0756.2016.03.014

下载:

下载: