-

刨花板是中国重要的人造板品种之一。2000年以来,中国就成为世界上重要的人造板生产大国。目前,刨花板被普遍应用于家具制造、室内装饰和包装材料等领域。当刨花板应用于室内装修和家具制造等室内场合时,如果一旦发生火灾,这些木质材料则为加速和扩大火灾埋下隐患,因此不经过阻燃处理的木质材料被列为可燃性木质材料[1]。为了提高刨花板的应用价值,提高该材料的阻燃性,世界上有很多科研工作者都对阻燃刨花板的性能和开发进行了研究[2-4]。这些研究包括阻燃刨花板的制备工艺、产品性能、原料开发和新产品制备等[5]。在中国高楼林立的大中型城市,一旦发生火灾,造成的人员伤亡将不可估量,所以在中国生产研究低毒、持久和环保的阻燃型人造板将具有尤为重要的现实意义。在前人对阻燃刨花板进行研究和开发以及笔者对阻燃胶合板制备和工业化研究[6-7]的基础上,本研究选取了3种不同的阻燃剂,2种不同的木质原料——木质刨花和工业大麻秆刨花和3种不同的胶黏剂——脲醛树脂胶黏剂(UF),酚醛树脂胶黏剂(DF)和异氰酸酯胶黏剂(MDI)来制备阻燃刨花板。本研究所采用的工业大麻Cannabis sativa是一种供工业利用的大麻品种,其结构和纤维形态是类似于阔叶材的低密度非木质材料[8-9],纤维细胞壁的力学性能较其他农作物秸秆、针叶材和阔叶材纤维细胞壁的力学性能要低[10];可用于制备轻质高强的结构材料和刨花板[11-12]。本研究将进一步分析利用工业大麻秆制备的阻燃刨花板与木质阻燃刨花板之间的性能差异,为制备出阻燃性能优良的刨花板奠定基础。

HTML

-

木质原料:本实验中分别采用木质刨花(80%云南松Pinus yunnanensis和20%其他杂木)和工业大麻秆刨花为原料,来制备刨花板。木质刨花由新飞林人造板有限公司提供;工业大麻秆刨花采用产于云南的工业大麻秆刨花作为实验材料,由云南省农业科学研究院提供,刨花为自制刨花。测氧指数时,2种原料在不增加氧气,即空气中的含氧量就可以导致材料燃烧;另外测烟密度时,材料很容易燃烧,无法计算烟密度。

胶黏剂:本实验中所采用的胶黏剂为脲醛树脂胶黏剂、酚醛树脂胶黏剂和异氰酸脂胶黏剂等3种。脲醛树脂胶黏剂:由新飞林人造板股份有限公司提供,性能指标分别为黏度(30)30~32 s(4#涂料杯),pH 9.0,固体含量为60%~61%,游离甲醛含量2.5 g·kg-1;氯化铵黏(NH4Cl)为脲醛树脂胶固化剂,市购,分析纯;酚醛树脂胶黏剂(PF):自制,固含量51%~53%,棕红色;异氰酸酯胶黏剂:市购,固含量为100%,褐色。

阻燃剂:试验中共采用3种阻燃剂,分别为无机阻燃剂(FR-A),有机阻燃剂(FR-B)和聚磷酸铵阻燃剂(FR-C)。FR-A为无机型阻燃剂,其主要化学成分为硼酸、硼砂等;FR-B为有机型阻燃剂,其主要化学成分为磷酸铵、硫酸铵等;FR-C阻燃剂的主要成分为聚磷酸铵,详见参考文献[8]。

-

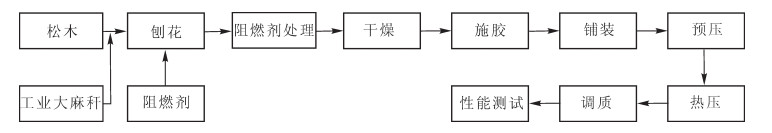

采用单因素法进行,阻燃刨花板的工艺流程见图 1所示。

刨花阻燃处理:将3种阻燃剂制成质量分数为12%的溶液,利用喷枪均匀的施加到刨花中,阻燃剂的添加量为绝干刨花的10%;再将刨花置于70 ℃的恒温烘箱中烘至含水率为3%~5%。

板材制备:板材厚度为10 mm,目标密度0.70 g·cm-3,板材幅面为300 mm × 300 mm × 10 mm。在板材制备中,采用的3种胶黏剂分别为脲醛树脂胶黏剂、酚醛树脂胶黏剂和异氰酸酯胶黏剂。这3种胶黏剂采用的制备工艺具体如下:以脲醛树脂为胶黏剂制备刨花板时,制板工艺参数为热压温度为150 ℃,热压时间30 s·mm-1,施胶量12%;以酚醛树脂为胶黏剂时,制板工艺参数为热压温度为150 ℃,热压时间50 s·mm-1,施胶量10%;以异氰酸酯为胶黏剂时,制板工艺参数为热压温度为150 ℃,热压时间30 s·mm-1,施胶量5%;同一实验条件下重复进行3次,每次实验均按照相关标准进行性能测试,测试结果取3次平行实验的平均值。

-

力学性能:按照国家标准GB/T 17657-1999《人造板及饰面人造板理化性能试验方法》进行力学性能测试;测试结果见表 1所示。

原料 序号 阻燃剂 胶黏剂 弹性模量/MPa 抗折强度/MPa 内结合强度/MPa Ts/% 1 FR-A 1 523 15.14 0.67 45.76 2 FR-B 脲醛树脂 1 430 16.18 0.54 31.18 3 FR-C 1 408 14.24 0.53 68.54 4 空白 1 940 18.05 1.12 23.78 5 FR-A 1 432 12.53 0.29 112.99 工业大麻秆 6 FR-B 酚醛树脂胶黏剂 1 800 14.94 0.35 69.57 7 空白 1 815 15.14 0.54 70.66 8 FR-A 1 816 15.86 0.46 10.80 9 FR-B 异氰酸酯胶黏剂 1 853 16.77 0.50 6.90 10 FR-C 1 533 12.99 0.28 17.58 11 空白 1 026 19.22 0.58 10.05 12 FR-A 1 040 12.68 0.41 39.14 13 FR-B 脲醛树脂 1 351 17.71 0.53 23.54 14 FR-C 1 217 15.57 0.4 52.83 15 空白 1 812 23.12 1.05 22.42 16 FR-A 1 339 12.58 0.41 49.14 木质材料 17 FR-B 酚醛树脂胶黏剂 1 865 15.51 0.32 63.42 18 空白 1 733 12.53 0.47 55.14 19 FR-A 1 158 7.44 0.66 7.73 20 FR-B 异氰酸酯胶黏剂 1 774 16.98 0.67 11.19 21 FR-C 1 216 15.15 0.54 11.13 22 空白 928 18.47 1.21 11.94 国家标准 12.50 0.28 8.00 国家标准 1 800 14.00 0.35 8.00 Table 1. Physical and mechanical properties of particle board panel with different resin and fire retardant agents

燃烧性能:按国家标准GB/T 2406.2-2009《塑料用氧指数法测定燃烧行为第二部分:室温试验》和国家标准GB/T 8627-2007《建筑材料燃烧或分解的烟密度试验方法》分别进行板材氧指数和烟密度的测试;测试结果见表 2~5所示。

原料 阻燃剂 胶黏剂 最大烟密度/% 烟密度等级/%) 氧指数/% 无 21.0 工业大麻秆 脲醛树脂 35.64 17.53 23.5 酚醛树脂胶黏剂 39.96 11.11 23.8 无 异氰酸酯胶黏剂 36.93 13.83 22.4 木材 无 21.0 脲醛树脂 39.39 21.70 26.5 酚醛树脂胶黏剂 27.63 7.86 24.4 异氰酸酯胶黏剂 51.04 13.45 25.3 Table 2. Flammability of particle board panels without fire retardant agents

原料 阻燃剂 胶黏剂 最大烟密度/% 烟密度等级/% 氧指数/% 脲醛树脂 26.66 13.84 34.9 工业大麻秆 酚醛树脂胶黏剂 9.10 3.09 29.5 异氰酸酯胶黏剂 28.17 15.04 35.5 FR-A 脲醛树脂 26.31 14.55 40.6 木材 酚醛树脂胶黏剂 7.31 3.74 33.4 异氰酸酯胶黏剂 32.71 16.56 41.3 Table 3. Flammability of particle board panels with FR-A type fire retardant agents

原料 阻燃剂 胶黏剂 最大烟密度/% 烟密度等级/% 氧指数/% 脲醛树脂 35.35 16.65 30.4 工业大麻秆 酚醛树脂胶黏剂 16.87 6.73 30.0 异氰酸酯胶黏剂 43.08 19.89 34.3 FR-B 脲醛树脂 27.62 20.94 38.5 木材 酚醛树脂胶黏剂 23.99 6.88 34.8 异氰酸酯胶黏剂 40.34 21.29 39.3 Table 4. Flammability of particle board panels with FR-B type fire retardant agents

原料 阻燃剂 胶黏剂 最大烟密度/% 烟密度等级/% 氧指数/% 工业大麻秆 脲醛树脂 32.47 13.65 29.3 FR-C 异氰酸酯胶黏剂 44.43 23.68 30.8 木材 脲醛树脂 41.96 22.49 40.5 异氰酸酯胶黏剂 50.79 27.31 41.3 Table 5. Flammability of particle board panels with FR-c type fire retardant agents

1.1. 实验材料

1.2. 试验方法

1.3. 性能测试

-

在利用不同胶黏剂制备阻燃刨花板时,当以酚醛树脂为胶黏剂时,在刨花板中添加入阻燃剂FR-C时,板材会爆板,无法压制出合格的板材。所以,当阻燃剂为FR-C时,只有脲醛树脂和异氰酸酯胶黏剂2种板材。由表 1可知:在刨花板中添加阻燃剂FR-A,FR-B和FR-C后,利用3种胶黏剂制备的工业大麻杆刨花板和木质刨花板的静曲强度(MOR)和内结合强度(IB)均降低,但除了利用异氰酸酯胶黏剂制备的木质刨花板外,其余刨花板静曲强度和弹性模量均可满足国家普通刨花板的标准要求(IB≥0.28,MOR≥12.5)。在利用脲醛树脂为胶黏剂制备刨花板时,当在板材中添加阻燃剂FR-A,FR-B和FR-C时,板材的弹性模量均降低;在利用酚醛树脂为胶黏剂制备刨花板时,当在板材中添加阻燃剂FR-A时,板材的弹性模量降低,而在板材中添加阻燃剂FR-B时,板材的弹性模量略有增加,并且工业大麻秆刨花板和木质刨花板的变化趋势一致;在利用异氰酸酯为胶黏剂制备刨花板时,在板材中添加3种阻燃剂后,板材的弹性模量均增加。可见,阻燃剂会对利用不同胶黏剂制备的刨花板的物理力学性能产生不同影响,可能在阻燃剂和异氰酸酯胶黏剂之间存在着一定的协同作用,但作用机理还有待进一步进行研究。在利用脲醛树脂和酚醛树脂为胶黏剂时,在板材中加入阻燃剂后,板材的吸水厚度膨胀率增加,均不能满足国家普通刨花板对吸水厚度膨胀率的标准要求(TS≤8%);而在利用异氰酸酯为胶黏剂时,当加入阻燃剂FR-A和FR-B后,板材的吸水厚度膨胀率减小,而当加入阻燃剂FR-C后,板材的吸水厚度膨胀率增加。进一步说明,阻燃剂和异氰酸酯胶黏剂之间存在着一定的协同作用,具体的作用机理有待进一步进行研究。下面将进一步分析不同胶黏剂对利用不同阻燃剂制备的刨花板阻燃性能的影响,以进一步确定胶黏剂和阻燃剂对刨花板阻燃性能的影响,并确定出最佳的刨花板制备工艺。

-

根据国家标准GB 8624-1997《建筑材料燃烧性分级方法》的标准要求,若建筑材料需要通过B1级检测时,氧指数和烟密度等级必须同时满足下列条件:氧指数(IOI)≥32,烟密度等级(RSDR)≤75。下面将具体分析3种胶黏剂对利用3种阻燃剂、2种木质原料制备的刨花板的燃烧性能的影响,以确定胶黏剂、阻燃剂对刨花板阻燃性能的影响,为制备性能优异的阻燃剂和刨花板奠定基础。

由表 2可得:工业大麻秆和木材均是易燃材料,在无添加阻燃剂和胶黏剂时,非常容易燃烧所以无法计算其烟密度等级,而在空气中就可以燃烧,其氧指数即为空气中氧气的浓度,约21%;在利用3种胶黏剂制备工业大麻秆刨花板、不添加阻燃剂时,以酚醛树脂为胶黏剂制备刨花板时,板材的烟密度等级最小,氧指数最大即略高于利用脲醛树脂为胶黏剂制备的刨花板的氧指数,而利用异氰酸酯为胶黏剂时板材的氧指数最小。在利用3种胶黏剂制备木质刨花板时,以酚醛树脂为胶黏剂制备刨花板时,板材的烟密度等级最小;氧指数要低于利用脲醛树脂和异氰酸酯制备的刨花板的氧指数。可见,当利用不同胶黏剂制备刨花板时,板材的燃烧性能不仅受到胶黏剂种类的影响,还受到了木质原料种类的影响;当木质原料相同时,胶黏剂对板材发烟性具有显著的影响而对板材阻燃性的影响不明显;在未添加阻燃剂的条件下,酚醛树脂的抑烟性能最好,异氰酸酯胶黏剂次之,脲醛树脂胶黏剂最差。此外, 所有样品的烟密度曲线均随测试时间的延长而增加, 即当测试结束时其烟密度达到最大值,该值为最大烟密度。

由表 3可得:当在刨花板中添加阻燃剂FR-A后,利用脲醛树脂和酚醛树脂胶黏剂制备的刨花板的烟密度等级均降低,脲醛树脂刨花板的烟密度为空白板的67.05%~78.95%,酚醛树脂胶黏剂刨花板的烟密度为空白板的27.8%~47.58%;而利用异氰酸酯制备的工业大麻秆刨花板和木质刨花板的烟密度增加,为空白刨花板的108.74%~123.12%;进一步说明异氰酸酯胶黏剂和阻燃剂之间出现了协同作用,并且这种作用会增加刨花板材的发烟量。与此同时,利用3种胶黏剂制备的刨花板的氧指数均增大,当利用异氰酸酯为胶黏剂时,板材的氧指数最大;利用酚醛树脂为胶黏剂时,板材的氧指数最小;与空白刨花板相比,脲醛树脂刨花板的氧指数变化幅度为148.51%~153.20%,酚醛树脂胶黏剂刨花板的氧指数变化幅度为123.95%~136.89%,异氰酸酯刨花板的氧指数变化幅度为158.48%~163.24%即异氰酸酯有利于提高板材的阻燃性能。

由表 4可得:当在板材中添加阻燃剂FR-B后,利用脲醛树脂制备的刨花板的烟密度等级略有降低,为空白板的94.98%~96.50%;酚醛树脂胶黏剂制备的刨花板的烟密度显著降低,为空白板的60.58%~87.53%;而利用异氰酸酯制备的刨花板的烟密度则显著增加,为空白刨花板的143.82%~158.29%。利用3种胶黏剂制备的刨花板的氧指数均增加,但增加的幅度主要取决于胶黏剂的种类和原料种类,异氰酸酯制备的刨花板的氧指数最大;与空白刨花板相比,脲醛树脂刨花板的氧指数变化幅度为129.36%~145.28%,酚醛树脂胶黏剂刨花板的氧指数变化幅度为126.05%~142.62%,异氰酸酯刨花板的氧指数变化幅度为153.13%~155.34%。即酚醛树脂胶黏剂可有效的降低板材的发烟量并显著提高板材的阻燃性能。

当在板材中添加阻燃剂FR-C时,利用酚醛树脂胶黏剂为胶黏剂制备刨花板时,会释放出大量的氨气,造成了产品的分层和鼓泡,不会压制出合格的板材,所以在板材制备中只讨论了脲醛树脂和异氰酸酯2种胶黏剂对刨花板燃烧性能的影响(表 5)。利用异氰酸酯制备的刨花板的烟密度等级和氧指数要高于利用脲醛树脂为胶黏剂制备的刨花板的烟密度等级和氧指数;异氰酸酯刨花板的烟密度等级和氧指数分别为空白板的171.22%~203.04%和137.50%~163.24%;脲醛树脂刨花板的烟密度等级和氧指数分别为空白板的77.87%~103.64%和124.68%~152.83%。结果和在板材中添加阻燃剂FR-A和FR-B一致,但和不添加阻燃剂的空白刨花板不一致,进一步说明异氰酸酯胶黏剂和阻燃剂之间存在一定的协同作用,但这种作用过程和反应机制将在今后进一步进行研究。

2.1. 胶黏剂对板材物理力学性能的影响

2.2. 胶黏剂对板材燃烧性能的影响

-

不同的原料、胶黏剂和阻燃剂会对刨花板的物理力学性能、燃烧性能产生不同的影响;添加阻燃剂后利用脲醛树脂、酚醛树脂胶黏剂为胶黏剂制备的刨花板大多数物理力学性能指标都被降低,而异氰酸酯胶黏剂刨花板的弹性模量均得到了提高。在不添加阻燃剂的情况下,酚醛树脂胶黏剂和异氰酸酯胶黏剂刨花板的烟密度小于脲醛树脂刨花板的烟密度,而氧指数则无明显差异。在添加阻燃剂后,酚醛树脂胶黏剂具有很好的抑烟效果,但阻燃效果较差;异氰酸酯胶黏剂具有很好的阻燃效果但会增加刨花板材中的发烟量;脲醛树脂刨花板具有一定的阻燃作用,但因阻燃剂种类的不同,烟密度具有不同的变化趋势。原因可能是木质原料具有不同的物理结构,对阻燃剂具有不同的吸附作用;阻燃剂与胶黏剂之间存在着协同作用,可能是阻燃剂的某些化学成分可以与胶黏剂发生化学反应,但需要进一步进行验证和分析。将进一步对阻燃剂与胶黏剂之间的作用机制以及阻燃剂和胶黏剂对板材燃烧气体排放的种类和烟气毒性进行研究,以制备出阻燃、抑烟效果均优并可以保留板材物理力学性能的阻燃剂。

DownLoad:

DownLoad: