-

中国是世界上竹种类与面积最丰富的国家,竹林面积高达540万hm2[1],竹子是中国第二大森林资源。毛竹Phyllostachys edulis和车筒竹Bambusa sinospinosa等大径级竹材的工业化利用较为成熟[2],方竹Chimonobambusa quadrangularis和佛肚竹Bambusa ventricosa等小径级竹林由于径级小、材性差,仅少数用于制浆造纸、竹工艺品或观赏用竹等领域,利用率较低。目前,对大径级竹材烘焙过程中固体和液体产物的特性研究较多。LI等[3]和张雨等[4]研究了烘焙温度对毛竹固体产物特性的影响,结果发现:随着烘焙温度升高,固体产物中碳元素相对含量升高,氧元素降低,热值升高,竹材能量密度得到显著提高。CHEN等[5]和ZHENG等[6]则发现:随着烘焙温度升高,生物油含水率降低,酸类物质相对含量降低,酚类相对含量升高,pH值升高;认为烘焙预处理有效减少了生物油中水分和含氧化合物,提高了生物油稳定性。而烘焙预处理对小径级竹材热解产物特性的研究还未见报道。本研究以方竹为原料,采用程序控温管式炉、热重红外联用仪(TG-FTIR)、热解气质联用仪(Py-GC/MS)等仪器开展烘焙(210,240,270和300 ℃)试验与热解(550 ℃)试验,探究烘焙温度对方竹热解过程气、固、液三相产物的影响,为小径级竹材的能源化利用提供基础数据。

HTML

-

方竹取自云南竹材加工厂,经圆锯机(CS70EB,德国费斯托)截断,去除竹节、竹青和竹黄,保留竹肉。竹肉经破碎机(KL-120B,滕州三浓机械厂)破碎、碾磨机(ML-1000,武义海纳仪器科技有限公司)碾磨成粉末;筛选出粒径为180~220目的样品,105 ℃烘箱干燥12 h后,装袋干燥保存备用。称取5 g方竹原料(ck)置于坩埚,利用程序控温管式炉(TL1200,南京博蕴通仪器科技有限公司)以10 ℃·min-1速率加热,升温至目标温度210(BT210),240(BT240),270(BT270)和300 ℃(BT300)后保温30 min得到烘焙样品,封袋保存。

-

采用元素分析仪(Vario EL Ⅲ,德国Elementary公司)分别测定原料及烘焙样品中碳、氢、氮、硫元素相对含量,其中氧元素含量采用差减法计算。使用微机量热仪(ZDHW-8A,鹤壁市科达仪器仪表有限公司)测定原料及烘焙样品产物热值。根据GB/T 28731-2012《固体生物质燃料工业分析方法》分别测定原料及烘焙样品中固定碳含量、挥发分及灰分含量。各指标测定3次,取平均值。烘焙固体产物质量产率=烘焙后固定产物质量(g)/原料质量(g)×100%,能量产率=质量产率(%)×烘焙后固体产物热值(MJ·kg-1)/原料热值(MJ·kg-1)×100%。

使用体积比为1:4的硝酸-乙醇混合溶液测定原料及烘焙后样品纤维素含量:称取(1.0±0.1)g烘焙产物加入至250 mL锥形瓶,加入25 mL硝酸乙醇,沸水浴加热1 h,重复4~5次,直至样品颜色变白,过滤、洗涤、干燥后置于105 ℃烘箱烘干至恒量,即得到纤维素。根据GB/T 2677.10-1995《造纸原料综纤维素含量的测定》测定综纤维素含量,半纤维素含量可通过综纤维素含量减纤维素含量得到。根据国标GB/T 2677.8-1994《造纸原料酸不溶木素含量的测定》测定木质素含量。

采用X射线衍射仪(XRD-6000,日本岛津公司)在5°~40°角度范围内分别扫描测定原料及烘焙样品结晶度。采用傅里叶红外光谱仪(Nicolet 6700,美国尼高力公司)在4 000~500 cm-1波长范围内分别扫描后鉴定原料及烘焙样品表面官能团。采用X射线光电子仪(Thermo Scientific Escalab 250Xi,美国)分析烘焙产物表面含碳官能团种类及含量,使用Al Ka线作为辐射源,以284.8 eV的C1s峰位置作为内标,通过Avantage软件拟合C1s峰曲线(C1s即碳原子中1s轨道电子被激发所测光电子能量),其他元素含量以碳元素作为参考,每种官能团含量由相应峰面积确定。

-

采用热重红外联用仪(TGA 8000-Frontier, 美国PerkinElmer公司)在线分析方竹烘焙产物的热解失重规律和热解挥发分组分。分别称量35.0 mg原料及烘焙后固体产物置于坩埚中,以10 ℃·min-1速率升至550 ℃进行热解,载气为高纯氮气,载气流量45 mL·min-1。傅里叶红外分析仪分辨率与光谱区域分别为4 cm-1和4 000~500 cm-1,频谱扫描时间间隔8 s。

-

采用快速热解炉(CDS 5200, 美国Chemical Data Systems公司)和气相色谱/质谱(7890B-5977B, 美国Agilent公司)联用仪在线分析方竹烘焙产物的热解生物油组分。称取0.3 mg原料放置于石英管中部,并在原料的上下位置分别填入石英棉,防止样品被载气带出。热解炉以10 ℃·ms-1速率升温至550 ℃,热解产物通过色谱质谱联用仪(GC/MS)实现在线分析。载气为高纯氦气,载气流速1 mL·min-1,传输线和进样口温度为分别为280和230 ℃,色谱柱为HP-5MS毛细管柱(30 m × 0.25 mm × 0.25 μm),分流比为1:40。柱箱的升温程序为:从40 ℃(保持3 min)以10 ℃·min-1升至280 ℃(保持3 min)。质谱工作条件为:70 eV,质荷比(m/z)为50~400,离子源温度230 ℃,四级杆温度150 ℃,全扫描模式,溶剂延迟时间3 min。根据NIST谱库并结合相关研究文献,对热解液体产物进行组分鉴定和相对含量分析,用峰面积归一化法计算各有机组分相对含量[7-8]。

1.1. 试验材料

1.2. 方竹原料及烘焙产物性能分析

1.3. 方竹原料及烘焙产物的热解试验

1.3.1. 热重红外联用(TGA-FTIR)分析

1.3.2. 热解-气质联用(Py-GC/MS)分析

-

由图 1可知:原料碳元素相对含量为47.27%,氧元素为45.47%;随着烘焙温度升高,烘焙产物碳元素相对含量逐渐升高至54.61%,氧元素则逐渐降低至38.83%,氧碳比由0.72减小到0.53;氧元素主要以二氧化碳(CO2)、一氧化碳(CO)和水蒸气(H2O)等形式脱除[7]。原料中半纤维素相对含量为30.43%,纤维素为42.01%,木质素为27.56%;随着烘焙温度升高,烘焙产物半纤维素相对含量降低至2.59%,木质素逐渐升高到58.65%,而纤维素相对含量呈现先升高(48.76%)后降低(38.76%)趋势。烘焙产物工业组分相对含量变化归因于三组分热稳定性存在差异。马中青等[9]和陈登宇等[10]对三组分的热失重规律研究发现:半纤维素热解温度为185~325 ℃,其分子结构为非晶结构,存在较多支链,受热易降解成挥发分,稳定性最差。纤维素热解温度为270~400 ℃,主要由葡萄糖聚合物组成,没有支链,分子结构规整,因此热稳定较强。木质素由多糖组成,化学键的活性范围覆盖广,因此降解温度范围较宽(100~800 ℃)[11]。方竹原料固定碳相对含量为18.25%,挥发分为79.93%,灰分为1.82%;随着烘焙温度升高,烘焙产物中固定碳和灰分相对含量升高,挥发分则降低;与此同时,质量产率和能量产率逐渐减低,能量密度增加,高位热值则由原料的18.32 MJ·kg-1升高至21.65 MJ·kg-1。由此认为,烘焙预处理有效降低了原材料中的氧碳比,提升了热值,增加了固定碳相对含量,从而提高固体产物能量密度。

-

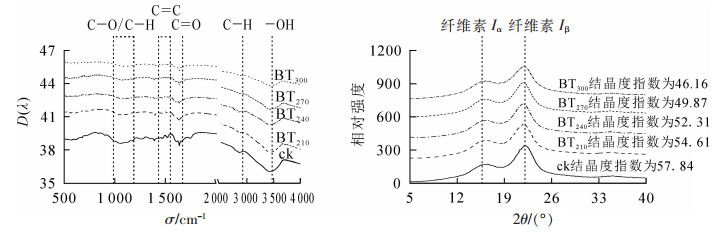

随烘焙温度升高,固体产物各官能团的吸光度值均有一定减小,存在5条显著的特征吸收带。由图 2可知:3 460 cm-1处的伸缩振动为羟基(-OH)官能团吸收带。羟基主要来源于水分子,随着烘焙温度升高,游离水、结合水中羟基脱除,半纤维素、纤维素中脂族羟基脱落[12];与原料相比,羟基官能团吸收带峰值降低,表现为烘焙产物水分相对含量减小,吸光度值降低。2 840 cm-1对应碳-氢(C-H)键的伸缩振动。碳-氢官能团一般来源于脂肪族的亚甲基(-CH2)和烷烃的甲基(-CH3)[12-13]。随烘焙温度升高,半纤维素木聚糖单元、纤维素葡聚糖单元发生脱甲基、亚甲基反应,生成甲烷(CH4),导致C-H官能团吸光度值逐渐降低[14]。在1 778 cm-1处的碳=氧(C=O)键主要源于半纤维素、纤维素中的羧基和羰基,随烘焙温度升高,半纤维素中4-O-甲基葡聚糖醛酸单元和纤维素葡聚糖单元发生脱羧、脱羰反应生成CO2和CO,是C=O官能团吸光度值降低的原因[14]。1 400 cm-1频带为苯环骨架碳=碳(C=C)键的伸缩振动,随烘焙温度升高吸光度值有所下降。此外1 600,1 580,1 500 cm-1特征峰的出现,最可能的物质是单环芳烃[15]。1 475~1 000 cm-1频带为典型的指纹区,该区域主要由芳香族苯基及酚类的碳-氧(C-O)键、C-H键和碳链伸缩振动产生,随着烘焙温度升高,吸光度值逐渐下降,归因于木质素苯丙单元醚键的断裂导致固体产物酚类相对含量减少[7]。

-

前期研究发现[13],2θ=18°与2θ=22°(2θ为角度,就是入射光线和反射光线的夹角)分别为纤维素非结晶区与纤维素结晶区。图 2发现:烘焙温度对固体产物结晶度的影响主要表现为16°的纤维素Iα(三斜晶系)结构峰和22°的纤维素Iβ(单斜晶系)结构峰。随着烘焙温度升高,纤维素结晶区与非结晶区峰值均降低,结晶度指数由57.84降低至46.16,以22°结晶区吸收强度下降尤为明显;原因在于随温度升高,纤维素分子间氢键发生变化[16-17],结晶纤维素逐渐降解为无定形纤维素,导致结晶度指数降低。

-

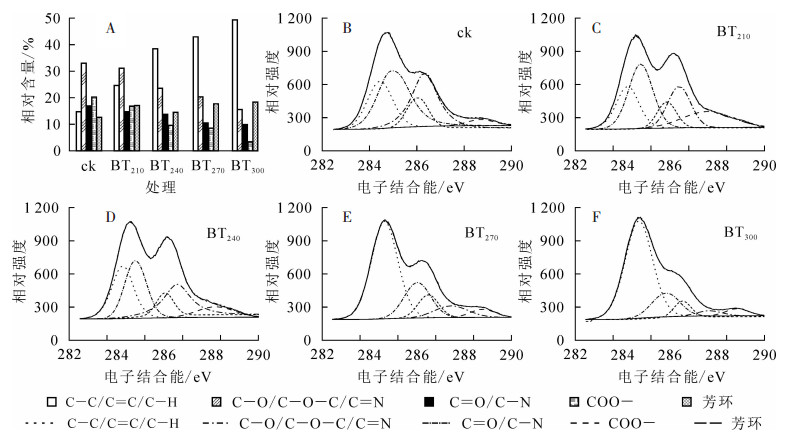

图 3A为5类官能团含量图,原料(图 3B)、210 ℃烘焙产物(图 3C)、240 ℃烘焙产物(图 3D)、270 ℃烘焙产物(图 3E)和300 ℃烘焙产物(图 3F)的C1s图谱均解聚出5类峰。284.8 eV处为石墨/脂肪族碳峰(C-C/C=C/C-H);随烘焙温度升高,半纤维素、纤维素逐渐发生热降解,相比较于原料,固体产物石墨化程度加深,石墨/脂肪族特征峰(C-C/C=C/C-H)峰值逐渐升高,吸收强度增强[17]。285.9~286.2 eV处为(C-O/C-O-C/C=N)峰,主要来源为碳水化合物和木质素中的醚类物质;随烘焙温度升高,碳水化合物热降解,木质素苯丙单元醚键(C-O-C)断裂生成CO气体[18],是烘焙产物C-O/C-O-C/C=N峰值逐渐降低的原因。286.7~287.3 eV处代表羰基和奎宁类物质C=O/C-N峰;烘焙造成奎宁类物质C-N键断裂,半纤维素4-O-甲基葡聚糖醛酸单元发生脱羰反应,生成酮类、醛类和CO2气体,C=O吸收强度由此逐渐降低[15]。287.9~288.9 eV处为羧基和酯基中COO-峰;随烘焙温度升高,纤维素葡聚糖单元发生脱羧反应,产生较多羧酸和酯类并释放CO2气体,吸收峰峰值逐渐降低。289.3~289.7 eV处为芳环特征峰;随烘焙温度升高,半纤维素木聚糖单元、纤维素葡聚糖发生缩聚反应和环化反应,导致芳香族含量增加[19-20],芳环特征峰峰值由此增大。

-

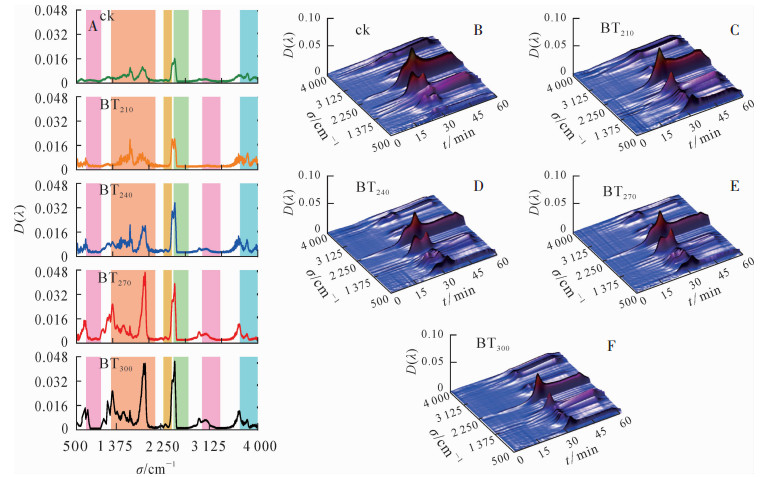

由图 4A可知:随着烘焙温度升高,固体残余物相对含量由对照(ck)19.98%升高至300 ℃的37.02%。由图 4B可知:热解过程分为脱水、快速热解和慢速热解3个阶段。脱水阶段温度为30~150 ℃,该阶段质量损失主要源于游离水、结合水和细胞腔吸附水的脱除[13]。快速热解阶段为主要失重区,烘焙温度由210 ℃升高至270 ℃时,聚合度和热稳定性较低的半纤维素[12]中糖苷键断裂,生成挥发性物质(CO2,CO和碳氢化合物等),纤维素和木质素相对含量随之增加并成为热解的主要物质,最大失重率达118.6 g·kg-1·min-1;当烘焙温度由270 ℃升高至300 ℃,半纤维素热解基本完成,结晶纤维素和木质素成为主要热解物质,纤维素葡聚糖单元大量分解,木质素富集程度更显著,最大失重速率逐渐减小。至慢速热解阶段,半纤维素、纤维素与木质素未反应完全部分再次降解,失重速率趋于平缓。

-

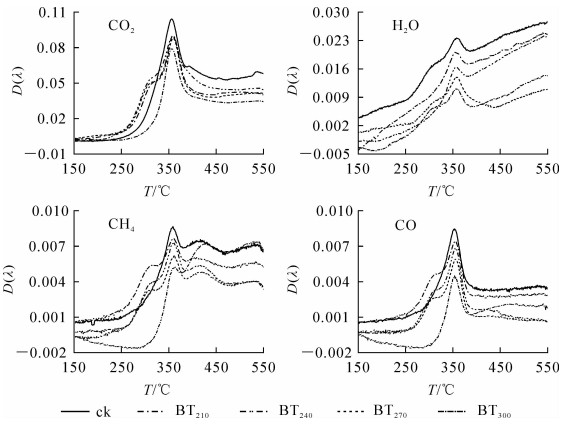

对最大失重峰处的二维红外图(图 5A)和原料(图 5B)、210 ℃烘焙产体(图 5C)、240 ℃烘焙产体(图 5D)、270 ℃烘焙产体(图 5E)、300 ℃烘焙产物(图 5F)的热解3D-FTIR图分析,根据Lambert-Beer定律,认为特征吸收峰的吸光度越高,对应挥发分的相对含量也就越高。从整体来看,随烘焙温度的升高,各个峰的峰值逐渐下降,吸光度降低,表明热解产物挥发分相对含量逐渐减少。对方竹原料及烘焙产物热解过程最大失重峰处所对应的小分子气体产物的二维红外图的分析发现(图 6),不同吸收峰处对应官能团的气体组分不同,小分子气体组分(如H2O,CH4,CO2及CO等)存在5条显著的特征吸收带。其中3 734 cm-1处为-OH的伸缩振动,代表性物质为水分子;随热解进程加剧,游离水、结合水脱除,半纤维素、纤维素侧链中脂族羟基裂解,热解过程水分相对含量逐渐降低[12, 21],导致特征吸收峰峰值随之降低。2 938 cm-1处为CH4气体中的C-H键的伸缩振动。CH4主要来源于半纤维素、纤维素基本单元侧链连接的甲基(-CH3)亚甲基(-CH2-)的裂解和木质素苯丙单元甲氧基的(-OCH3)的热降解[15];烘焙使得半纤维素、纤维素大量分解,-CH3和-CH2-官能团大量脱落,木质素-OCH3官能团裂解,生成的CH4气体相对含量总体呈下降趋势[22],表现为C-H特征吸收峰峰值逐渐降低。2 358 cm-1和667 cm-1是CO2气体C=O键的伸缩振动,CO2气体主要来源于半纤维素4-O-甲基葡糖醛酸单元发生脱羧、脱羰反应和纤维素葡聚糖单元C1,C2位置上开环反应中的脱羰基反应[13, 15, 23]。随烘焙温度升高,半纤维素葡萄糖醛酸单元大量分解,纤维素葡聚糖单元和木质素苯丙单元成为热解的主要物质,CO2相对含量逐渐降低,吸光度值逐渐下降。2 173 cm-1处为CO气体中C-O键伸缩振动。CO的形成有2条途径,其一为木质素苯丙基单元中醚键的断裂,例如β-O-4,α-O-4等连接键的断裂[22, 24];另一种途径是纤维素中的葡聚糖单元和半纤维素中的糖基单元开环反应过程中羧基的裂解[25]。热解造成结晶纤维素与木质素的降解,导致CO相对含量降低,吸光度值逐渐下降。除此之外,热解还产生H2及部分有机气体组分,其中H2源于苯环脱氢形成芳香烃反应,烘焙产物中苯环结构增加,导致热解过程中H2相对含量逐渐;有机气体组分可以通过热解气质联用分析仪进行分析[22]。

-

方竹热解后得到酸类、酚类、呋喃类、酮类和醛类等5类液体组分。由表 1可知:随烘焙温度升高,热解液体中酸类相对含量由12.69%降低至9.06%,主要成分是乙酸。研究认为[21, 25]:乙酸主要来源于半纤维素中C2位置上木聚糖连接的O-乙酰基基团的脱落,并伴随乙醛、乙烯酮、丙酸等物质的生成。烘焙预处理使得方竹半纤维素大量分解,热解油中乙酸相对含量显著减少,生物油酸性成分逐渐降低,进而提高了热解油的抗腐蚀性[22, 26]。生物油中酚类相对含量由32.52%上升至38.19%。烘焙导致方竹半纤维素和纤维素大量分解,木质素相对含量提高;而酚类物质主要源于木质素苯丙烷单元结构的侧链和苯环上的C-C键和β-O-4,α-O-4醚键的裂解以及结晶纤维素葡聚糖单元的热降解,而较高温度又使得纤维素葡聚糖上的双环结构通过C1和C2位置上C-O键断裂生成自由基碎片,再聚合生成苯酚等物质,导致愈创木酚与其他酚类物质相对含量提高。呋喃类和醛类物质相对含量分别从29.8%和11.85%降低至10.85%和4.03%,酮类含量由9.46%上升至24.34%。随烘焙温度的升高,半纤维素、纤维素热降解反应加剧,半纤维素、纤维素中吡喃环发生开环和重排,半纤维素O-乙酰基木聚糖单元和4-O-甲基葡糖醛酸单元发生热降解,是热解油中呋喃类、醛类相对含量逐渐下降,酮类相对含量增加[31]的原因。

类别 化合物 相对含量/% 原料 210 ℃烘焙 240 ℃烘焙 270 ℃烘焙 300 ℃烘焙 酸类 乙酸 5.46 5.96 6.09 5.30 2.79 十四烷酸 0.49 0.26 0.23 0.48 0.58 3, 5-二甲氧基-4-羟基苯乙酸 3.04 3.07 3.44 2.98 2.73 正十六烷酸 2.10 1.73 1.09 1.49 1.99 十八烷酸 1.60 1.18 0.64 0.78 0.97 总和 12.69 12.20 11.49 11.03 9.06 酚类 苯酚 0.42 0.68 0.89 1.05 0.95 2-甲氧基-苯酚 2.13 2.99 3.59 3.57 5.59 4-乙基-苯酚 0.82 0.81 0.80 0.90 0.63 甲酚 0.34 0.58 0.49 0.79 1.09 邻苯二酚 0.48 0.57 0.48 1.01 0.96 4-甲基-1, 2-苯二酚 0.40 0.26 0.61 1.23 3.92 2-甲氧基-4-乙烯基苯酚 8.49 8.61 9.06 8.43 4.83 2, 6-二甲氧基-苯酚 5.33 5.91 6.79 10.56 12.40 2-甲氧基-4-(1-丙烯基)苯酚 0.76 0.64 1.03 0.96 2.73 反式异丁香酚 4.66 4.55 4.46 3.22 1.41 (E)-2, 6-二甲氧基-4-(丙-1-烯-1-基)苯酚 9.69 9.05 8.94 5.94 3.70 总和 32.52 34.65 37.14 37.66 38.19 呋喃类 糠醛 0.53 0.34 0.64 2.58 3.21 2, 3-二氢-苯并呋喃 29.27 27.37 24.81 15.40 7.64 总和 29.80 27.71 25.45 17.98 10.85 酮类 2-羟基-3-戊酮 1.11 1.87 2.08 2.61 5.23 1-(3-羟基-4-甲氧基苯基)-乙酮 0.42 1.08 2.01 2.60 4.89 1-(4-羟基-3-甲氧基苯基)-2-丙酮 2.61 2.87 2.94 2.42 1.45 3, 5-二甲氧基苯乙酮 4.57 4.99 5.69 7.21 9.99 1-(4-羟基-3, 5-二甲氧基苯基)-乙酮 0.61 0.51 0.41 2.01 2.78 总和 9.46 11.32 13.13 16.14 24.34 醛类 2, 3-二羟基苯甲醛 0.35 0.31 0.36 ND ND 4-羟基-苯甲醛 1.68 1.20 0.79 ND ND 香草醛 2.51 2.45 1.86 1.41 1.09 4-羟基-3, 5-二甲氧基-苯甲醛 1.74 1.64 1.74 1.85 2.94 松柏醛 5.59 4.95 4.71 2.67 1.19 总和 11.85 10.55 9.46 5.93 4.03 说明:“ND”表示未检测出 Table 1. Effect of torrefaction temperature on the relative content of organic components in pyrolysis oil

2.1. 烘焙产物分析

2.1.1. 温度对烘焙产物基本特性影响

2.1.2. 烘焙产物的傅里叶变换红外光谱(FTIR)分析

2.1.3. 烘焙产物X射线衍射图谱(XRD)分析

2.1.4. 烘焙产物的X射线光电子图谱(XPS)分析

2.2. 烘焙固体产物的TGA-FTIR分析

2.2.1. 烘焙固体的热失重规律(TGA)分析

2.2.2. 三维傅里叶变换红外光谱(3D-FTIR)分析

2.2.3. 生物油组分及其相对含量分析

-

不同温度烘焙预处理对方竹热解行为有影响,表现为随烘焙温度升高,热解三态产物存在差异。烘焙产物碳元素相对含量由47.27%升高至54.61%,氧元素相对含量则由45.47%降低到38.83%,高位热值从18.32 MJ·kg-1升高到21.65 MJ·kg-1。热解液体产物有机组分由酸类、呋喃类、酚类、酮类和醛类5类构成,酚类相对含量最高,为38.19%,主要来源于木质素苯丙基单元(如β-O-4,α-O-4连接键)的断裂。热解气由H2O,CO2,CO,CH4和少量H2组成。其中,CO2相对含量最高,随烘焙温度升高,热解气中CO2,H2O,CO,CH4相对含量逐渐降低,H2相对含量有所升高;烘焙预处理能有效去除生物油中的水分和含氧物质,烘焙后固体再热解过程的液体产物可作为一种液体燃料,用于工业化利用。

DownLoad:

DownLoad: