-

蔺草 Juncus effusus 属灯心草科 Juncaceae 多年生宿根性草本,俗称席草,原产亚热带,中国、日本、韩国以及东南亚一些国家都有栽培。在中国主要分布于浙江、江苏、安徽、江西、上海及四川等省市。蔺草是一种重要的经济作物,宁波是全国最大的蔺草栽植和草制品加工出口基地,连续数年栽培面积超过10 000 hm2,占全国栽培面积3/5以上,一般草茎干质量为9~12 t·hm-2,年出口创汇近10亿元[1]。目前,蔺草的主要栽培品种有‘冈山3号’‘伊索拉米’‘鄞蔺1号’‘农林1号’‘农林4号’‘宁草’‘白头草’和‘长草’等[2-3]。蔺草茎秆是一种优质天然纤维,具有表面接触性好,吸湿放湿性优越,保温隔热性能强等特点[4]。其茎秆多用于编织榻榻米、草席、草垫、草帽等十大系列百余种日常用品。近年来,中国蔺草种植规模日益扩大,但品种混杂情况严重,极大地影响和限制了蔺草制品的生产需求。因此,培育优质的蔺草品种,对中国蔺草产业的发展极其重要。茎秆的力学性能研究是利用遗传工程改变作物内部结构与机械性能,选育良种的前提[5]。关于农作物茎秆力学特性方面,国内学者主要对小麦 Triticum aestivum,水稻 Oryza sativa,玉米 Zea mays,苎麻 Boehmeria nivea,工业大麻 Cannabis sativa,蓖麻 Ricinus communis 等进行了深入的研究工作,并取得较多的成果[6-11],国外学者也开展了大量的相关研究[12-16],但关于蔺草茎秆力学特性的研究还鲜见报道。本研究以5份蔺草种质为研究对象,通过对蔺草底部茎秆解剖构造和力学特性进行观测测试,分析有关特性的影响因素及其变化规律,为蔺草机械收割技术参数设计提供理论支持,为进一步选育优良蔺草品种及其开发利用提供参考。

HTML

-

5份蔺草种质均由新艺蔺草制品公司收集并栽培于“中国蔺草之乡”的浙江省宁波市鄞州区,分别用XY001,XY002,XY003,XY004和XY007表示。其中,XY001,XY004和XY007来源于日本,XY002来源于浙江鄞州,XY003来源于四川眉山。试验选用2014年6月上旬收割的成熟期蔺草,高度均大于900 mm,长势良好,无病虫害,并尽量避免对茎秆的机械损伤。试验用样均取自距基部100 mm以上部位。

-

解剖构造观测:蔺草收割期田间取样后,立即用FAA[(V(甲醛):V(冰醋酸):V(体积分数为70%乙醇)=5:5:90)]固定液固定样品。每份蔺草种质随机选取3株,选取3根·株-1,长度为10~15 mm。采用常规石蜡切片法制作切片,用番红-固绿染色,然后置于显微镜下观察不同种质蔺草底部茎秆的解剖构造,并测量茎秆横切面直径、维管束数量、茎壁厚等相关参数(茎壁厚指茎秆横切面上从表皮到基本组织与髓部相连处的厚度)。纤维形态观测:取长度为30 mm的干燥茎秆放入试管中,注水至淹没材料,然后将试管放入水浴锅中加热煮沸,以排除其中的空气。将试管的水倒出,加入体积分数为30%的硝酸和适量氯酸钾放在水浴锅中煮,待茎秆变成黄白色或白色,并至软化,倒去硝酸。待试管冷却后,用蒸馏水冲洗数次至无酸。注水于试管中,用手指按压试管口用力振荡,至茎秆细胞被分离,加入1~2滴番红试剂染色。用毛笔和解剖针挑出少许材料置于载玻片上,加水1滴,制成临时切片,置于显微镜下观测。每份蔺草种质至少测量100个试样。

-

将干燥试样粉碎,45 ℃恒温干燥12 h,过40目筛,保存。粗纤维质量分数测定依据GB/T 5009.10-2003《植物类食品中粗纤维的测定》,含水量测定依据GB/T 1931-2009《木材含水率测定方法》。主要仪器为VELP FIWE6纤维素测定仪。

-

试验在浙江农林大学国家木质资源综合利用工程技术研究中心力学实验室进行。利用CTM 6000型微机控制电子万能力学试验机,参考GB/T 1040-2006《塑料和复合材料拉伸强度、拉伸模量和拉伸应力—应变关系的测定方法》对蔺草茎秆进行力学性能测试。试样长度为80 mm,试验标距为40 mm,每份蔺草种质制作10个试样,试样含水率为12%。

-

采用Excel 2007软件对数据进行统计并作图,利用数据处理系统SPSS 19.0软件对相关数据进行统计和方差分析,方差分析采用SSR法。

1.1. 试验材料

1.2. 试验方法

1.2.1. 解剖构造研究

1.2.2. 粗纤维质量分数测定

1.2.3. 力学性能测试

1.3. 数据处理

-

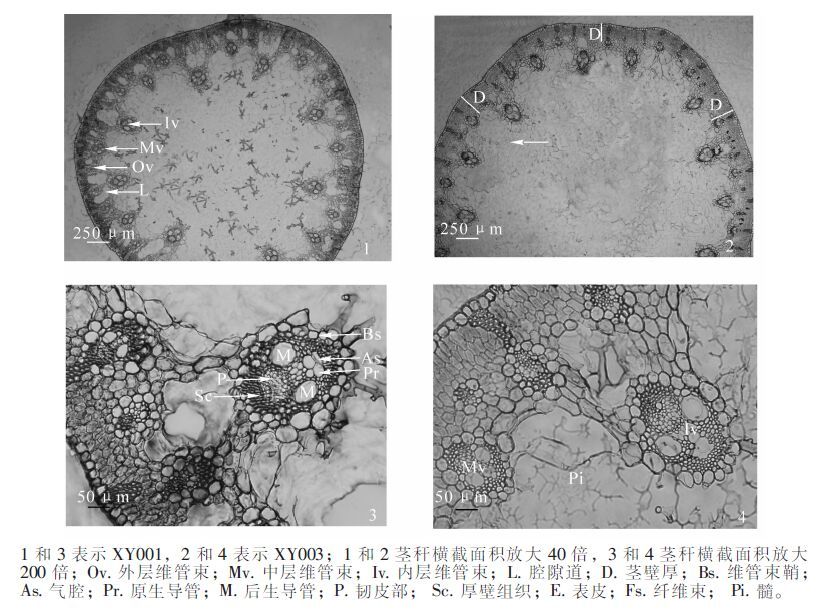

XY001和XY003蔺草底部茎秆的横切面微观结构见图 1,其余3份与这2份相似。可以看出:蔺草底部茎秆的横切面呈圆形或近圆形,5份蔺草种质底部茎秆横切面的基本结构大致相同,分为表皮、基本组织、维管束和髓,基本组织包括同化组织和纤维2部分。最外层为1层表皮细胞构成的表皮,表皮外被角质层。表皮下的5~7层是由排列较为紧密的薄壁细胞和在薄壁细胞之间间隔排列的成束纤维构成的基本组织。基本组织内紧靠表皮的2~3层细胞紧密排列呈栅状,细胞内富含叶绿体,即为同化组织。纤维束沿茎秆切向周围紧靠表皮层与基本组织间隔排列,在蔺草茎秆的横切面上纤维束成楔形,狭的一端径向地伸向基本组织,其大小和伸入的程度不等。大多数纤维束的内侧与外围维管束的外侧相接。维管束分散在基本组织中,数量多,大小不一,大致呈外、中、内3层排列。中、外2层维管束数量多,但其横切面面积小;内层的维管束数量少,但横切面面积大,并向内突入髓部较深。髓部由无数多孔疏松的星状细胞组成,又称海绵组织,位于基本组织和维管束以内,居于茎的中部,占有较大面积。茎秆结构外坚内松,外密内疏,坚韧且富有弹性,吸湿力强。在基本组织的细胞间还存在着与维管束相间排列的数个腔隙道,腔隙道横切面为圆形或椭圆形的空腔。

-

5份蔺草种质底部茎秆横切面直径、茎壁厚、茎壁厚/茎半径,以及维管束数目统计结果见表 1。由表 1可见:5份蔺草种质茎秆维管束的总数目为47~58个,其多少的排列顺序为XY004>XY003>XY001>XY002>XY007;横切面直径为3.78~4.09 mm,大小的排列顺序为XY001>XY004>XY007>XY002>XY003;茎壁厚313.20~361.80 μm,其大小的排列顺序为XY004>XY003>XY001>XY007>XY002;茎壁厚/茎半径比值为0.161~0.189,其大小排序为XY003>XY004>XY001>XY007>XY002。方差分析表明:5份蔺草种质之间横切面直径无显著性差异;XY002和XY007之间茎壁厚无显著性差异,与其他3份之间均存在显著性差异(P<0.05);XY003与XY004之间茎壁厚/茎半径无显著性差异,与其他3份之间均存在显著性差异(P<0.05)。

阎早种质 维管束数目/个 横切面直径/mm 茎壁厚/μm 茎壁厚/茎半径 内层 中、外层 总数 XY001 12 41 53 4.09 ± 0.37 a 351.00 ± 29.69 a 0.172 ± 0.008 bc XY002 11 39 50 3.90 ± 0.32 a 313.20 ± 19.14 b 0.161 ± 0.009 c XY003 15 42 57 3.78 ± 0.19 a 358.00 ± 19.90 a 0.189 ± 0.004 a XY004 14 44 58 3.99 ± 0.11 a 361.80 ± 35.73 a 0.181 ± 0.013 ab XY007 10 37 47 3.91 ± 0.28 a 327.40 ± 21.36 ab 0.168 ± 0.006 c 说明:同列数据(平均值±标准差)后面不同小写字母表示5C水平显著差异。 Table 1. Comparison of micro-structure on five rush stems

-

XY001和XY003茎秆纤维细胞的形态见图 2,其余3份与这2份相似。可以看出:纤维细胞的长度大小不一,均呈纺锤形,中部较宽,两头较尖。中部粗细均匀,且有较厚的细胞壁,细胞壁上有具缘纹孔。

-

5份蔺草种质纤维的长度、宽度、腔径和壁腔比见表 2。由表 2可知:5份蔺草种质的纤维长度为681.47~712.04 μm,宽度为5.58~8.00 μm,腔径为2.34~3.94 μm,壁腔比为1.194~1.556。不同种质纤维的长度和宽度不同,长度的大小排列顺序为XY004>XY001>XY002>XY003>XY007,宽度的大小排列顺序为XY007>XY002>XY004>XY003>XY001。不同种质的壁腔比有明显的差别,大小排列顺序为XY003>XY004>XY001>XY002>XY007。方差分析表明:5份蔺草种质之间纤维长度均无显著差异;XY007与其他4份蔺草的纤维宽度之间均存在显著差异(P<0.05);XY003的壁腔比与XY004之间无显著性差异,与其他3份蔺草均存在显著差异(P<0.05)。

蔺草种质 长度/μm 变异系数 宽度/μm 变异系数 腔径/μm 变异系数 壁腔比 变异系数 XY001 710.59±126.52 a 0.18 5.58±1.08 c 0.19 2.48±0.77 c 0.31 1.373±0.499 bc 0.36 XY002 704.61±146.70 a 0.21 6.54±1.54 b 0.24 3.19±1.29 b 0.41 1.235±0.621 cd 0.50 XY003 684.01±127.55 a 0.19 5.66±1.16 c 0.21 2.34±0.76 c 0.33 1.556±0.583 a 0.38 XY004 712.04±165.58 a 0.23 6.34±1.72 b 0.27 2.67±0.98 c 0.37 1.497±0.521 ab 0.35 XY007 681.47±167.39 a 0.25 8.00±2.59 a 0.32 3.94±1.82 a 0.46 1.194±0.528 d 0.44 Table 2. Comparison of morphology of the rush fiber

-

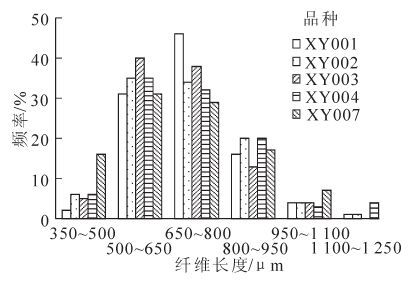

由图 3可以看出:5份蔺草种质纤维长度的分布频率有所差异,但整体分布规律基本相同,集中在350~1 250 μm,其中长度在500~800 μm长的纤维占到了60%以上,小于500 μm和大于800 μm的纤维所占比例很小。

-

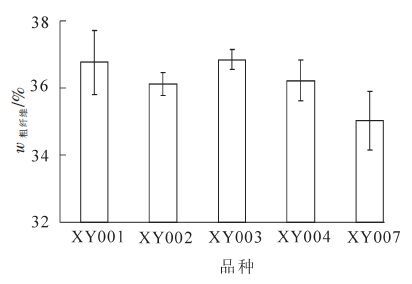

XY001,XY002,XY003,XY004和XY007的平均含水率分别为10.73%,10.60%,10.52%,9.35%,10.08%,其相应的粗纤维质量分数测定结果见图 4。由图 4可以看出,5份蔺草种质粗纤维的质量分数为35.04%~36.85%,平均为36.20%,不同蔺草种质粗纤维质量分数的百分比有所不同,其高低排列顺序为XY003>XY001>XY004>XY002>XY007。方差分析表明:5份蔺草种质之间粗纤维质量分数无显著差异性(P>0.05)。

-

反应茎秆力学性能的指标有拉伸强度、剪切强度、弹性模量、刚性模量以及茎秆的压缩特性等。对5份不同种质蔺草底部茎秆进行抗拉测试,其力学性能指标测试结果见表 3。

蔺草种质 面积/mm2 最大拉力/N 拉伸强度/MPa 拉伸变形量/mm 拉伸弹性模量/MPa XY001 1.80±0.32 b 72.67±9.80 a 41.09±6.37 b 1.04±0.30 a 1 679.66±472.65 bc XY002 1.68±0.33 bc 61.59±7.29 b 38.13±10.23 b 0.94±0.19 a 1 640.58±313.30 bc XY003 1.17±0.11 d 69.06±10.62 ab 59.11±9.48 a 1.04±0.13 a 2 297.10±320.15 a XY004 1.47±0.28 c 72.71±11.06 a 51.52±14.80 a 1.05±0.19 a 1 998.21±611.47 ab XY007 2.24±0.49 a 71.89±12.60 a 33.28±8.44 b 0.93±0.20 a 1 438.23±251.74 c 说明:同列数据(平均值±标准差)后面不同小写字母表示5%水平显著差异。 Table 3. Mechanical properties of stems of five rush genetic resources

-

对蔺草茎秆力学性能与微观结构、纤维的壁腔比及粗纤维素含量进行相关性分析,结果如表 3所示。由表 3可以看出:5份蔺草种质底部茎秆的横截面积为1.17~2.24 mm2,最大拉力为61.59~72.71 N,拉伸强度为33.28~59.11 MPa,拉伸变形量为0.93~1.05 mm,拉伸弹性模量为1 438.23~2 297.10 MPa。不同蔺草种质底部茎秆的横截面积有所不同,茎秆横截面积大小的排列为XY007>XY001>XY002>XY004>XY003,XY007的横截面积与其他4份之间均有显著的差异性;不同种质的拉伸强度、拉伸弹性模量有明显差别:拉伸强度的大小排列顺序为XY003>XY004>XY001>XY002>XY007,XY003的拉伸强度与XY001,XY002和XY007之间均有显著性差异,与 XY004之间无明显差异;拉伸弹性模量的大小排序与拉伸强度相同,XY003的拉伸弹性模量与XY001,XY002和XY007之间均有显著性差异(P<0.05)。由表 4可以看出:蔺草茎秆拉伸强度与维管束总数、茎壁厚/茎半径之间均具有极显著正相关关系,与纤维壁腔比呈显著正相关;拉伸弹性模量与维管束总数、茎壁厚/茎半径之间均呈极显著正相关,与纤维壁腔比呈显著正相关;拉伸强度和拉伸弹性模量与粗纤维质量分数之间均呈正相关,但不显著。

维管束总数 茎壁厚/茎半径 纤维壁腔比 粗纤维质量分数 拉伸强度 0.818** 0.740** 0.584* 0.258 拉伸弹性模量 0.724** 0.748** 0.663* 0.398 说明:*表示显著相关(P<0.05),**表示极显著相关(P<0.01) Table 4. Correlation analysis between anatomical structure and mechanical properties

2.1. 茎秆解剖构造研究

2.1.1. 茎秆微观结构观察

2.1.2. 茎秆微观结构相关参数

2.1.3. 纤维形态分析

2.1.4. 纤维的长度、宽度、腔径和壁腔比

2.1.5. 纤维长度分布频率

2.2. 粗纤维质量分数

2.3. 茎秆力学性能研究

2.4. 茎秆解剖构造与力学性能的关系

-

拉伸强度指材料产生最大均匀塑性变形的应力。在拉伸试验中,试样到断裂为止所承受的最大拉伸应力就是拉伸强度。拉伸变形量是用来反映拉伸前后材料纤维变形程度的参量,拉伸变形量小,说明材料纤维的韧性好。拉伸弹性模量指在弹性范围内拉伸应力与相应拉伸应变之比,主要反应的是抗弹性变形的能力,弹性模量越大,刚性越强,变形越小,不易被拉断,在构件的理论分析和设计计算时,拉伸弹性模量是经常被用到的一个重要力学性能指标[9-10, 17]。抗拉测试中,蔺草底部茎秆横截面积最大的是XY007,最小的是XY003,不同种质之间最大拉力和拉伸变形量相差不大,拉伸强度和拉伸弹性模量最大的都是XY003,最小的是XY007,结果与上述描述相符合。5份蔺草种质底部茎秆的最大拉力范围为61.59~72.71 N,拉伸强度为33.28~59.11 MPa,拉伸弹性模量为1 438.23~2 297.10 MPa。与其他3份种质相比,XY003和XY004底部茎秆具有较高的强度和良好的弹性。郭维俊等[9, 18]对小麦茎秆力学性能进行测试,得出小麦成熟期茎秆的最大拉力为182.38~242.74 N,抗拉强度为30.36~52.65 MPa,弹性模量为1 143.44~1 985.86 MPa;段传人等[10]研究显示:水稻茎秆拉伸强度极限8.70~14.21 MPa,拉伸弹性模量1 640~2 670 MPa;高梦祥等[19]对玉米秸秆的力学特性进行测试,得出茎叶连接力为0.7~16.0 N,叶鞘抗拉力为3.0~21.0 N,叶鞘抗冲击能量为0.5~3.8 J,茎秆抗冲击能量为23.0~42.8 J。O′ DOUGHERTY等[20]研究表明:小麦秸秆拉伸强度2 112~3 112 MPa,剪切强度4 191~7 126 MPa,杨氏模量4 176~6 158 GPa,刚性模量267~547 MPa,秸秆成熟度、含水率等对以上参数都有影响。国外学者所测小麦力学性能与国内有所不同,这可能与不同种源、栽培条件、测试处理方法等有关[6]。将蔺草底部茎秆力学性能与国内研究的小麦和水稻进行相比,可以看出小麦茎秆的最大拉力约是蔺草的3倍,拉伸强度相差不大,拉伸弹性模量比蔺草的小;水稻茎秆的拉伸强度极限小于蔺草底部茎秆,拉伸弹性模量两者相差不大。可见蔺草底部茎秆具有较高的强度和良好的弹性,有利于蔺草生长和抗倒伏。

有关茎秆力学性能与其微观结构关系的研究已有很多报道。王芬娥等[9]认为小麦茎秆具有较高的强度和良好的弹性,其承载能力取决于机械组织的厚度、维管束的数量以及各组织及其细胞之间的连接形式和连接强度;段传人等[10]指出,水稻茎秆的力学性能主要由茎粗、茎壁厚、大小维管束数目所决定;赵春花等[21]发现牧草茎秆力学性能主要取决于机械组织厚度和维管束组织数量,以及各组织及其各细胞之间的连接形式和连接强度。张西良等[22]认为,黄瓜Cucumis sativus藤秸茎秆强度主要由表皮、机械组织和维管束承担,薄壁组织起连接和传递载荷的作用。日本蔺草不同品种的坚韧性和弹性与其内部的组织形态特征密切相关[23-24]。江浙地区蔺草品种解剖结构与茎秆光洁度、坚韧性和弹性密切相关[2-3, 25]。本研究发现:蔺草茎秆力学性能与其维管束总数目、茎壁厚/茎半径均呈极显著正相关,结果与前人研究结论相一致。此外,角质层的加厚方式及表皮细胞壁加厚程度是影响蔺草坚韧性的因素之一。蔺草茎的横切面呈圆形或椭圆形,由表皮、基本组织、维管束和髓组成。表皮细胞排列致密,且外面覆盖有较厚而硬的角质层,对表皮有加固和保护的作用。基本组织内纤维的存在形式有2种:一是形成纤维束,一是形成维管束。纤维束近似楔形,向内延伸与外层维管束相连接,与茎内外2层维管束以间隔排列的形式贯穿于基本组织中。这种排列方式以及众多的数量使得蔺草茎秆具有很强的坚韧性。

5份蔺草种质纤维细胞大多呈纺锤形,中部粗细均匀,有较厚的细胞壁,细胞壁上有具缘纹孔。对苎麻属野生植物研究发现[26],离析纤维细胞形态多样,有的单纤维一端较尖细,另一端较钝圆,个别呈螺旋状扭曲;部分单纤维细胞壁较厚,均匀光滑,有的细胞壁有孔洞存在;存在分布不均匀的外突型、内陷型、平滑型结节。张艳[27]发现:龙须草Eulaiopsis binata纤维较细,表面有明显纵纹,无扭转,无明显横结。俞春华等[28]发现,香蕉Musa nana等5种植物纤维大多纵向平直、具有横节、无天然扭曲。蔺焘等[29]测得棉Gossypium spp. 秆皮部纤维的平均长度为(1 484.43 ± 753.78) μm,宽度为(18.90 ± 6.61) μm;潘明珠等[30]测得蓖麻纤维的长度分布范围为0.95~1.38 mm,宽度范围为21.80~30.11 mm,平均壁腔比范围为0.13~0.22。根据国际木材解剖学会(1937年)公布的纤维长度分级标准:纤维长度大于1.6 mm为长纤维,在0.9~1.6 mm为中等纤维,小于0.9 mm为短纤维[31],故蔺草纤维属于短纤维。稻草纤维的长度为920.0 μm,宽度为8.1 μm;玉米秆的纤维长度为990.0 μm,宽度为13.2 μm[16]。将蔺草纤维形态与上述研究结果相比,蔺草纤维的长度和宽度都比较小,壁腔比较大。纤维的壁腔比是胞壁厚度与胞腔直径之比,蒋坤云等[32]对乔木单根抗拉性能与微观结构和纤维的关系进行研究,发现纤维单根抗拉特性与木纤维的壁腔比成正相关,纤维的胞壁厚,胞腔小,材料密实,表现的强度大。试验发现,蔺草茎秆纤维的壁腔比与茎秆拉伸强度和拉伸弹性模量呈显著正相关,5份蔺草种质纤维壁腔比的大小排列顺序为XY003>XY004>XY001>XY002>XY007,拉伸强度和拉伸弹性模量的大小排列顺序为XY003>XY004>XY001>XY002>XY007。这些结果与前人研究结果相符合。说明蔺草茎秆纤维的壁腔比与拉伸强度、拉伸弹性模量密切相关,细胞壁越厚,细胞腔越小,纤维的拉伸强度和拉伸弹性模量越大。

粗纤维是植物细胞壁的主要成分,在硫酸的作用下,试样中的糖、淀粉、果胶质和半纤维素经水解除去后,再用碱处理,除去蛋白质及脂肪酸,剩余的残渣为粗纤维。5份蔺草种质粗纤维的质量分数为35.04%~36.85%,平均为36.20%,XY003的最高。林燕萍等[33]研究认为,茶树嫩梢的力学特性与粗纤维质量分数关系密切,最大应力、断裂应力与弹性模量随着粗纤维质量分数的增加而增大,最大力点应变与断裂应变随着纤维素质量分数的增加而减小。蔺草茎秆拉伸强度、拉伸弹性模量与粗纤维素质量分数之间有一定的相关性,XY003粗纤维的质量分数最高,其拉伸强度和拉伸弹性模量也最大,研究结果与林燕萍等[33]的结论较一致,说明蔺草茎秆的拉伸力学性能和粗纤维质量分数有一定的关系。关于蔺草不同部位的解剖构造与力学性能差别还有待进一步研究。

DownLoad:

DownLoad: