-

无患子Sapindus mukorossi,又名肥皂果,落叶乔木,树高可达25 m,是典型的南方树种[1]。无患子果皮富含的皂苷成分具有良好的起泡性和去污性能,可作为天然活性物质用于洗发香波及各种洁肤护肤化妆品中[2-4],甚至还可用于清洁被有机物污染的土壤[5-6]。无患子果核无需抛光就可以串成手饰[7],如佛珠;果仁可以提炼木本生物柴油,油酸含量丰富[8],也可用于制作高级润肤油、润滑油、航空与军用油,是开发生物质能源的理想原料[9-11]。近年来,国内外对无患子的研究和开发应用日益增多,无患子产业将来必然成为中国一个独具特色的产业[12]。从无患子果皮中提取与加工皂苷是无患子产业的最重要环节之一,无患子果皮含有大量皂苷可以通过水提法[13-14]或有机溶剂萃取法提取。其中,有机溶剂萃取法主要以乙醇[15]和正丁醇[16]萃取为主,但考虑到所用溶剂易挥发或有毒性,故高纯度提取法都还处于初步研究阶段,离实现规模化生产还存在成本高、可操作性差等缺点;而水提法以水作为萃取介质,成本低,工艺稳定,虽然提取物中往往会萃出其他杂质,但可采用微波法[17]或超滤法[18]对皂苷进行分离纯化,得到高纯度皂苷。因此,在目前一线生产中,采用了水提法提取皂苷,但处理果皮萃后物时采用的是人工捞取的方法,这种方法会导致效率低、车间黏滑与皂苷浪费等一系列问题,而国内外现存的农产品干燥机[19-21]结构大多较为复杂、能耗大。针对以上问题,本研究研制了一种双向旋转式无患子果皮萃后物滤水分料装置,并对其性能进行了测试。

HTML

-

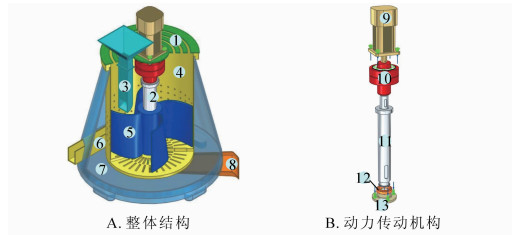

设计的双向旋转式无患子果皮萃后物滤水机如图 1所示,尺寸为600 mm × 590 mm × 766 mm。该装置包括机架、动力传动机构、进料机构、滤水分料机构和沥水机构。滤水机的动力传动机构包括电机、联轴器、主轴、轴承及轴承端盖。选用的电机功率为300 W,转速为90~1 400 r·min-1,安装在机架上,电机输出轴通过联轴器连接主轴的一端;主轴的另一端依次安装轴承和轴承端盖,并与滤水分料机构连接。在滤水分料机构中,为了减小装置运行时搅动叶片被果皮卡住的概率,将叶片与沥水内桶的间距设置为浸水后果皮弯曲有效厚度(即为果皮凹面朝上,水平放置所测得的最大高度),平均为5 mm。在出料机构中,采用了切线形长条导槽,出料口在垂直半径方向上的投影长度可为内桶半径的10%~50%,此处选取20%。本装置通过动力传动机构向滤水分料机构提供动力,实现滤水分料机构及沥水机构对浸水无患子果皮的双向旋转式脱水。

-

滤水方式如图 2A和图 2B所示,当搅动叶片由电机控制正向旋转时,浸水无患子果皮以一定速率从进料漏斗进入沥水内桶,并被搅动叶片带动正向旋转,果皮上的游离水将因离心作用被甩出,水将从沥水内桶侧壁与底部排出,进入沥水外桶,并从沥水外桶内底面中心向下流至沥水导槽直至流出装置。

出料方式如图 2C所示,当装置正向转动一定时间即游离水被充分甩出后,搅动叶片由电机控制反向旋转,脱水无患子果皮在搅动叶片带动下以一定速率反向旋转。由于搅动叶片的构造,使得其反向旋转时,脱水无患子果皮贴着沥水内桶的侧壁运动。当转到与出料导槽对应的切线位置时,果皮将沿着沥水内桶的切线方向从出料导槽中排出至装置外,至此实现浸水无患子果皮的脱水以及果皮与萃取液的固液分离。

1.1. 双向旋转式无患子滤水机结构

1.2. 工作原理

-

为验证搅动叶片的功能实现情况,对果皮在搅动叶片作用下的受力情况进行了分析。在此将果皮简化为半球壳体,由于搅动叶片为正向旋转弧度的四叶扇,在任意轴向位置处,径向切面各不相同,可设果皮和叶片内侧廓线切线的平行线与果皮和转动中心的连线夹角为θ,果皮质心和转动中心的连线段长度为R。当果皮的转动半径改变时,即R发生改变,所在位置处的叶片轴向偏角各不相同,可设果皮与叶片接触点处的叶片轴向偏角为α。由于进料时,搅动叶片已开始转动,故取果皮不受底板作用力的情况进行力学分析,F为叶片对果皮的驱动力,由叶片轴向偏角可分解为F1与F2;f为叶片对果皮的摩擦力,可分解为f1与f2。A为向视图(图 3)。

假设果皮能够受力平衡,则各力之间关系如式(1)~(4)所示。

式(1)~(4)中:θ为果皮和叶片内侧廓线切线的平行线与果皮和转动中心的连线夹角(rad);R为果皮质心和转动中心的连线段长度(m);α为果皮与叶片接触点处的叶片轴向偏角(rad);F为叶片对果皮的驱动力(N);F1与F2为叶片对果皮的驱动力的分力(N);f为叶片对果皮的摩擦力(N);f1与f2为叶片对果皮的摩擦力的分力(N);μ为果皮与叶片间的摩擦系数;m为果皮质量(kg);ω为叶片的转动角速度(rad·s-1);g为重力加速度,取9.8 m·s-2。

联立式(1)~(4)可得到式(5)。

由式(5)可知:要使平衡态存在,则必须满足式(6)。

下面对轴向偏角α进行分类讨论:①若α<90°,可得式(7)。

② 若α>90°,在此种情况下,轴向叶片旋向向上,可得式(8)。

由式(7)与式(8)可知:在理论上,2种情况下都可能存在果皮附着在叶片上达到平衡态的摩擦系数μ,但考虑到果皮与叶片间摩擦系数μ的实际值,式(7)中的θ必须大于45°才可能满足平衡态要求。其次,由于式(7)的区间范围小于式(8)的区间范围,故可知在叶片轴向偏角α<90°的情况下,果皮附着在叶片上的概率小于轴向偏角α>90°的情况下的概率。

在式(8)中:μ存在的概率相对较大的情况下,部分果皮在正转脱水时会被叶片不断托起,并不断碰撞进料漏斗与桶盖,使得大量果皮黏附在沥水内桶的上层桶壁,从而影响出料效果,大大降低出料效率。由式(7)可知:存在能让果皮附着在叶片上的摩擦系数μ的概率非常小,从而使得在正转时,大部分果皮分散在下层桶壁与桶底。因此,采用了轴向偏角α<90°的叶片旋向方式进行样机投产。

-

为进一步验证上述力学分析结论,本研究采用Adams虚拟样机仿真软件进行了仿真测试。在仿真中,建立的果皮模型为半球壳模型,初始位置在进料漏斗上方,为了使得仿真模拟过程更直观,隐藏了非关键零件,设置了沥水内桶底部圆心为参考点,由于设置的接触力较多,为使仿真结果精确,取步长为0.000 1 s,步数为0.8 s,转速为700 r·min-1,动静摩擦系数均为0.3。计算绘制出了果皮质心与该参考点的空间距离图象如图 4所示,从图 4可以直观看出:果皮通过进料漏斗进入沥水内桶,经过一段时间后,落在桶底,被搅动叶片带动贴在桶壁上一起转动,采用轴向偏角α<90°的搅动叶片后,结合实际材料摩擦系数,不论如何改变静摩擦与动摩擦系数,果皮均不会附着在叶片上,也不会从出料导槽中排出,故上文力学分析结论与1.2中滤水方式设想得证。

2.1. 力学分析

2.2. 运动学仿真分析

-

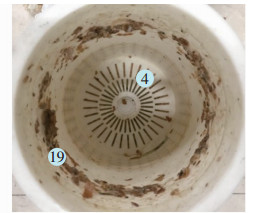

本研究研制的无患子滤水装置样机如图 5所示,传动机构、进料机构、滤水分料机构及沥水机构的关键件采用增材制造技术进行加工。对装配后的样机,本研究进行了滤水效果和出料效果实验。

滤水效果验证实验:取适量果皮,用滤布过滤后称取m1=100 g待用,将装置设定到规定转速后,再把样本放入分料装置中进行滤水,5 min后,用80%的转速(1 120 r·min-1)反转将果皮排出后,调节转速为0,并搜集排出的果皮和沥水内桶中残留果皮,放到电子天平上称量得总质量m2,称量完毕后,再将样本放入干燥箱中干燥至与实验前所测含水率相同的状态,称得质量m3,取下一份样本,设定不同转速(20%,40%,60%,80%满速转速,满速转速为1 400 r·min-1),重复上述步骤,重复3次·组-1,实验结果如表 1所示,滤前滤后果皮实验样品如图 6所示。滤水率n1计算式如式(9)所示。

转速/(r·min-1) 果皮滤水率/% 平均值/% 第1组实验 第2组实验 第3组实验 280 21.37 17.16 26.20 21.58 560 46.33 40.77 50.39 45.83 840 34.11 29.10 37.17 33.46 Table 1. Water filtration rate of the pericarp at different speeds

式(9)中:n1为滤水率;m1为用滤布过滤后的果皮质量(g);m2为滤后果皮总质量(g);m3为干燥后的果皮质量(g)。

随着转速的增加,滤水率先增大后减小;滤水率为20%~50%,符合滤水要求。由于设置的叶片与沥水内桶的间距为浸水后果皮的平均弯曲厚度,故在测试中几乎不存在搅动叶片被贴附在内桶桶壁上的果皮卡住的情况。在转速为1 120 r·min-1时,受切线形出料导槽与沥水内桶的安装误差影响,果皮易被高速转动的搅动叶片切碎,大量果皮附着在桶壁上,故造成了出料时只有少数果皮能够被搅动叶片推出,因此,该组实验数据无意义,未计算滤水率,故可说明在转速较高的状态下,本装置功能受限。在满速的80%转速滤水后的桶壁状态如图 7所示。

出料效果验证实验:准备步骤同滤水效果验证实验,用40%(560 r·min-1)的转速滤水5 min,再分别用40%(560 r·min-1),60%(840 r·min-1),80%(1 120 r·min-1)的转速反转出料,测量每次出料所耗时间与被排出的果皮质量m4,测量装置内残留果皮质量m5,重复3次·组-1。实验结果如表 2所示。

转速/(r·min-1) 耗时/s 平均耗时/s 果皮出料率/% 平均值/% 第1组实验 第2组实验 第3组实验 第1组实验 第2组实验 第3组实验 560 114.50 116.40 121.90 117.60 91.99 87.46 90.43 89.96 840 74.40 79.30 72.60 75.40 84.63 86.21 85.12 85.32 1 120 24.20 19.80 23.50 67.50 86.92 84.28 87.18 86.13 Table 2. Consumption time and discharge rate of pericarps at different speeds

出料率n2计算式如式(10)所示。

式(10)中:n2为出料率;m4为被排出的果皮质量(g);m5为沥水内桶中残留果皮质量(g)。

由表 2可知:当转速增大时,出料耗时显著缩短,但受出料口大小与切线形出料导槽形状限制,果皮会在出料口形成暂时堆积,从而影响出料效果,反而会使一部分果皮被搅动叶片托起高于出料口,从而沿桶壁转动,无法出料;由于加工处理水平有限,出料口边缘存在棱边,致使出料果皮在出料转速较大时会卡在棱边处,故转速较高的情况下,出料率会相对较低,但总体来说,平均出料率可达85%以上。通过调研福建省源容生物科技有限公司的实地生产情况,企业提出了初版样机出料率需达80%以上的要求,故本装置出料效果满足要求。

-

本研究设计了一种双向旋转式无患子果皮萃后物滤水分料装置,对其滤水过程进行了力学与Adams仿真分析以验证该设计方案,利用3D打印技术研制了样机,从滤水和分料效果角度对样机进行了性能测试。研究结果表明:①提出的新装置结构简单可靠,实用性强。装置采用了“双向旋转式”的理念,滤水分料机构及沥水机构实现了浸水无患子果皮的脱水与出料功能,操作简便高效,提高了无患子果皮皂苷萃取率。②采用的轴向偏角α<90°的搅动叶片设计方式可减小果皮在叶片上附着堆积的概率,促使果皮慢慢分散到下层桶壁与桶底上,从而使得装置能够更有效地完成脱水与出料工作。③通过对初版样机的性能测试,装置的平均滤水率可达45.83%,平均出料率可达85%以上,但仍需对搅动叶片与出料导槽加以设计改进。总的来说,初版样机能够较好地实现萃后物和皂苷混合物的分离、皂苷混合物的再回收利用,提高了无患子果皮皂苷的萃取率,滤水后的果皮更利于后续烘干和晒干工艺。

DownLoad:

DownLoad: