-

中国竹子资源丰富,素有“第二森林”之美称。中国竹林面积达720万hm2,约占世界总量的30%,种类、面积、蓄积量、产量均居世界首位[1]。竹材资源是中国除木材外第二大重要资源,而且竹材具有生长周期短、强度大和韧性好的特点,被认为是代替木材的最佳资源[2-4]。近些年来竹材产业的发展也愈来愈受到重视,毛竹Phyllostachys edulis竹秆被当成材料广泛用于各种生产,例如建筑材、造纸材、竹家具等[5]。但是竹材属于中空有节结构,表面覆有蜡质层,从而导致竹材利用率低,采伐剩余物累积量增大[6-7]。王红彦等[8]估算了中国林木剩余物数量的参考值,指出竹枝叶质量相当于竹材质量的38.07%,相当于竹材加工剩余物质量的62.00%。辜夕容等[9]也曾指出竹枝、竹梢竹叶等采伐剩余物占整竹的40.00%,由此估算出中国大概有720万t的竹材采伐剩余物[10]。这些采伐剩余物大部分都是被焚烧或者直接填埋[11-13],利用方式都比较初级,技术含量低,不仅造成环境污染,还对竹资源造成了极大的浪费。在中国森林资源日益减少的情况下,如何充分有效地利用这些剩余物,实现资源“零剩余”,已成为竹资源综合利用的一个紧迫问题。竹采伐剩余物和竹加工剩余物都是竹资源废弃物,由于其组成的微观结构存在区别,其性质也是不同的[14],这直接关系到其加工利用途径。目前,虽然关于毛竹性质和竹加工剩余物有相关的研究[15-16],但针对竹采伐剩余物尚未见报道。鉴于此,本研究拟对毛竹采伐剩余物竹枝和竹梢的主要性质进行分析,并对毛竹采伐剩余物通过传统工艺制浆造纸,测试纸张性能,从而判断毛竹采伐剩余物作为纸基材料的优劣性,以期为竹采伐剩余物的高效利用提供参考依据。

HTML

-

实验材料为4年生毛竹采伐剩余物,主要为竹枝和竹梢部分,取自安徽省金寨县青山镇(31.43°N,115.90°E)。竹材砍伐后分别收集竹枝和竹梢部分竹材,运回实验室后放置1周,达到气干状态。利用微型植物粉碎机粉碎,过筛,截取40~60目的竹粉,并贮存于密封袋中保存,供原料分析使用。其中竹秆是指取毛竹胸径部位的竹材。

-

毛竹采伐剩余物竹枝、竹梢部位化学成分参照GB/T 2677.3-1993《造纸原料灰分的测定》,GB/T 2677.6-1994《造纸原料有机溶剂抽出物含量的测定》,GB/T 2677.5-1994《造纸原料1%氢氧化钠抽出物含量的测定》,GB/T 2677.8-1994《造纸原料酸不溶木素含量的测定》和GB/T 2677.10-1995《造纸原料综纤维素含量的测定》[17],分别测定灰分、苯醇抽提物、10.0 g·L-1氢氧化钠抽提物、酸不溶木质素、纤维素和综纤维素等化学组成的质量分数,其中灰分采用坩埚法测定,苯醇抽提物采用索式抽提法测定,10.0 g·L-1氢氧化钠抽出物采用蒸煮法测定,综纤维素采用索式抽提和脱木素法测定,纤维素测定采用硝酸乙醇和α-纤维素方法测定,酸不溶木质素采用索式抽提和硫酸法测定。

-

分别取竹枝、竹梢竹粉样品,用苯醇[V(苯):V(乙醇)=2:1]抽提6 h脱脂,然后参照GB/T 2677.10-1994《造纸原料综纤维素含量测定》脱木素后,得到综纤维素。将得到的综纤维素加入到1 000 mL锥形瓶中,加入50.0 g·L-1的氢氧化钠,固液质量比m(固):m(液)=1:25,在60 ℃水浴中反应。4 h后,用纱布过滤,蒸馏水洗涤至中性,待滤液沉淀后,将上层清液移出,下面沉淀用滤纸抽滤,将所有的滤液pH值调制为pH 5.5~6.0。将调好的滤液浓缩后透析1周,再浓缩,冷冻干燥后得到半纤维样品。

-

用1.00 mol·L-1硫酸在105 ℃下浸泡半纤维素样品(5.0 mg)2.5 h后,过滤并稀释50倍,采用高效离子交换色谱(HPAEC, Dionex, ICS-3000, 美国)测定水解液中的单糖,该检测系统包括安培检测器,AS50自动进样器,PA-20柱(4 × 250 mm, Dionex)。流动相先用5.00 mmol·L-1氢氧化钠洗脱20 min,其次用溶解于5.00 mmol·L-1氢氧化钠的0.75 mmol·L-1醋酸钠梯度洗脱15 min,可分离出中性糖和醛酸。然后用200 mmol·L-1氢氧化钠冲洗柱子10 min,最后用5.00 mmol·L-1氢氧化钠平衡柱子5 min。分析过程中温度始终保持30 ℃。

-

将毛竹采伐剩余物竹枝、竹梢部位以及竹秆部位试样劈成火柴杆大小,取适量放入试管中,加入300.0 g·L-1的过氧化氢与冰醋酸[V(过氧化氢):V(冰醋酸)=1:1]配比溶液,淹没试样,放入70~80 ℃水浴锅中,直至试样变白为止,大约8 h。离析后在40倍显微镜下测定纤维长度和宽度。

-

采用傅里叶变换红外光谱仪(6670 Nicolei,美国)对毛竹采伐剩余物竹枝和竹梢样品进行分析,谱图扫描次数32次,分辨率为4 cm-1,光谱采集范围为4 000~400 cm-1。

-

毛竹采伐剩余物竹枝和竹梢的热解特性采用热重分析仪(209 Netzsch)进行测定。即随机称取2~5 mg热分析样品置于坩埚内,然后将坩埚放入热重分析仪。升温速率为20 ℃·min-1,最终温度为600 ℃,同时加入保护气氮气。

-

采用硫酸盐法对毛竹采伐剩余物进行蒸煮实验。根据对竹枝竹稍化学成分的分析以及对比其他竹材蒸煮工艺,选择以下参数:料液比m(料):V(液)=4:1,蒸煮最高温度为170 ℃,升温时间约30 min(100~170 ℃),保温为2 h,用碱量为200.0 g·L-1的氢氧化钠。按照GB/T 1546-2004《纸浆卡伯值的测定》的方法测定纸浆卡伯值。

-

取适量未漂白浆,使用PFI型立式磨浆机(ZQS7)打浆,打浆度为51 °SR,利用抄片机(M153200,MESSMER)抄造纸张,根据GB/T 454-2002《纸耐破度的测定》,GB/T 12914-2008《纸和纸板扩张强度的测定》,GB/T 455-2002《纸和纸板撕裂度的测定》综合评价纸张耐破、抗张和撕裂度性能。

1.1. 材料

1.2. 化学成分的测定

1.3. 半纤维素的提取及多糖的测定

1.3.1. 提取半纤维素

1.3.2. 多糖测定

1.4. 纤维形态测定

1.5. 红外光谱(FT-IR)分析

1.6. 热重分析

1.7. 蒸煮试验方法

1.8. 纸浆及纸张性能评价

-

植物纤维原料中纤维素、半纤维素及木质素3大成分直接影响了原料的用途。由表 1可知:毛竹采伐剩余物的硝酸-乙醇纤维素质量分数为403.6~342.9 g·kg-1,而α-纤维素质量分数约420.0 g·kg-1。其中,竹梢部位的硝酸-乙醇纤维素质量分数高于竹枝部位的,但都小于竹秆部位的(417.0 g·kg-1),而α-纤维素,竹枝与竹梢竹秆差不多,这是因为α-纤维素中还有抗碱的半纤维素,这也说明竹枝、竹梢中半纤维素较多,可以在打浆时增加纤维细纤维化程度[18]。与毛竹竹秆相比,采伐剩余物竹枝、竹梢含有较高的木质素,且竹枝、竹梢的木质素差异不大。表明毛竹采伐剩余物可作为生产木质素衍生物的原料。毛竹的竹梢综纤维素质量分数高于竹秆和竹枝,综纤维素一般用来表示原料中碳水化合物的多少,这与制浆得浆率的高低有关,也说明竹梢满足了纸浆材中对碳水化合物的需求。与毛竹竹秆相比,采伐剩余物灰分质量分数较高,其中竹枝中含有最高的灰分(26.5 g·kg-1)。与毛竹竹秆相比,采伐剩余物抽出物较高,其中竹枝的抽出物最高,这样会使制浆过程中浸渍药品消耗量增加,且抽出物质量分数在一定程度上可以预估原料在碱法制浆中的纸浆得率情况[19]。

部位 化学成分质量分数/(g·kg-1) 灰分 苯醇抽提物 10.0 g·L-1氢氧化钠抽提物 酸不溶木素 α-纤维素 综纤维素 硝酸-乙醇纤维素 竹枝 26.5 54.3 296.7 243.6 427.5 630.2 342.9 竹梢 8.5 36.7 256.7 245.0 434.8 708.8 403.6 竹秆 7.3 31.0 251.3 239.4 434.4 667.1 417.0 Table 1. Chemical constituents of the logging residues in Phyllostachys edulis

-

半纤维素在水中润胀性较好,会提高竹纤维细纤维化程度,增加纤维间的结合力[18]。半纤维素由酸水解可以成多种单糖。表 2可以看出:竹材半纤维素主要成分是木糖,无论竹枝还是竹梢,均在850.0 g·kg-1以上,表明竹采伐剩余物半纤维素中有大量木聚糖存在。第二大组分是阿拉伯糖。此外,还有少量的糖醛酸和葡萄糖,有微量的鼠李糖和半乳糖。糖醛酸主要是葡萄糖醛酸和半乳糖醛酸。与竹枝相比,竹梢的半纤维素中各种单糖均与竹枝的各个单糖差异不明显,其中鼠李糖、半乳糖、阿拉伯糖均比竹枝稍低。

部位 占总成分比例/% 质量分数/(g·kg-1) 鼠李糖 阿拉伯糖 半乳糖 葡萄糖 木糖 葡萄糖醛酸 半乳糖醛酸 竹梢 29.57 2.0 71.4 8.0 13.0 872.1 30.9 2.6 竹枝 29.38 2.3 78.6 10.2 11.1 864.2 30.9 2.6 Table 2. Composition of hemicellulose of the logging residues in Phyllostachys edulis

-

纤维形态是衡量造纸原料是否适用于造纸的一个重要指标,其包括纤维长度、纤维宽度和长宽比等指标,它们数值的大小直接影响了纸张性能。

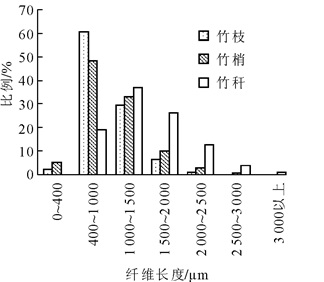

如表 3所示:竹秆的平均纤维长度>竹梢纤维长度>竹枝纤维长度,竹秆的纤维长度为514~3 391 μm,竹梢的最长纤维为2 947.3 μm,最短为128.9 μm,而竹枝纤维长度分散在115.9~2 545.9 μm。竹杆和竹梢、竹枝纤维长度差异显著(P<0.05)。竹枝、竹梢、竹秆平均宽度分别为15.05,16.47和15.55 μm,其宽度差异不大。竹秆的纤维长宽比最大,但竹枝、竹梢的长宽比差异并不明显,而竹杆与枝梢、竹枝的差异显著(P<0.05)。由图 1所示:竹枝的纤维长度60.62%分布在400~1 000 μm,29.62%以上分布在1 000~1 500 μm,还有少量分布在400 μm以下;竹梢的纤维长度约48.14%分布在400~1 000 μm,33.14%分布在1 000~1 500 μm,还有13.57%以上分布在1 500 μm以上;竹秆的纤维长度主要分布在1 500~2 500 μm,400 μm以下几乎没有,少量分布在2 500 μm以上。按照造纸原料要求[20],毛竹采伐剩余物可以作为造纸原料使用。

部位 纤维长度/μm 纤维宽度/μm 长宽比

(平均值±标准差)最大值 最小值 平均值±标准差 最大值 最小值 平均值±标准差 竹秆 3 391.0 514.0 1 643.66 ± 585.50 a 26.4 5.0 15.55 ± 3.77 b 123.12 ± 34.74 a 竹梢 2 947.3 128.9 1 030.70 ± 537.28 b 30.3 5.2 16.47 ± 7.39 a 64.70 ± 35.29 b 竹枝 2 545.9 115.9 948.54 ± 361.37 b 30.4 3.9 15.05 ± 4.38 b 65.54 ± 30.52 b 说明:同列不同字母表示差异显著(P<0.05),相同字母表示差异不显著 Table 3. Fiber morphology of the logging residues in Phyllostachys edulis

-

由图 2可知:毛竹采伐剩余物与竹秆在FT-IR图谱中的出峰位置相同,这表明毛竹采伐剩余物和竹秆的化学成分相同。3 435 cm-1处的吸收峰为羟基键的伸缩振动吸收峰,2 924 cm-1处的吸收峰为碳氢键的伸缩振动吸收峰,1 059 cm-1处的吸收峰为醚键的伸缩振动吸收峰。这些吸收峰均为典型的纤维素特征峰[21-22]。与毛竹竹秆相比较,竹枝和竹梢分别在1 510 cm-1处出现木质素吸收峰[23],且竹枝在1 510 cm-1处吸收峰相对强度更高,这与竹枝含有较高的木质素有关。此外,1 735 cm-1处的吸收峰为羰基键的伸缩振动吸收峰,1 249 cm-1处的吸收峰为乙酰基的伸缩振动吸收峰,均为半纤维素的特征吸收峰[24-25]。由FT-IR图谱可知:毛竹采伐剩余物与竹秆一样,均由纤维素、半纤维素和木质素构成,而3大素结构影响了毛竹采伐剩余物在蒸煮时的反应。

-

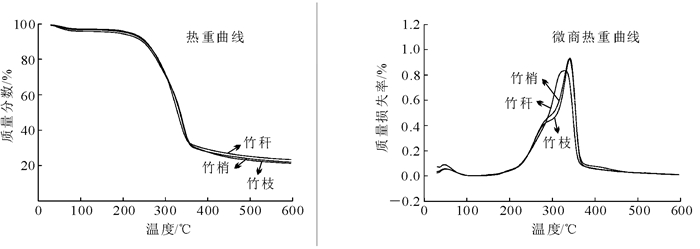

由图 3可知:毛竹采伐剩余物和竹秆一样,热降解过程相似主要包括3个阶段,但降解温度不同。第1阶段,竹枝、竹梢和竹秆热降解温度一致,均是从30 ℃到156 ℃,与毛竹竹秆相比,竹枝质量损失最大(4.50%),竹梢质量损失最小(3.11%),这可能是竹枝、竹梢和竹秆中水分析出的阶段。第2阶段,竹枝、竹梢的热降解温度从156 ℃到369 ℃,而竹秆部位的热降解温度则从156 ℃到360 ℃。这是纤维素、半纤维素和部分木质素发生降解的阶段,是热降解过程中的主要阶段。与毛竹竹秆相比,该阶段毛竹采伐剩余物的质量损失率较高,其中竹枝达65.10%,竹梢达66.98%。由图 3可知:毛竹采伐剩余物的最大热解温度高于竹秆部位的(330 ℃),其中,竹枝的最大热解温度为341 ℃,此时质量损失达50.88%;竹梢的最大热解温度为339 ℃,此时质量损失为51.86%。这可能与竹采伐剩余物中木质素含量较高有关。表明毛竹采伐剩余物的热稳定性稍优于竹秆,其中竹枝的热稳定性最好。第3阶段,毛竹采伐剩余物的热分解温度从369 ℃到595 ℃,而竹秆的则从360 ℃到595 ℃。该阶段竹枝、竹梢质量损失率分别达9.18%和7.94%。通过毛竹竹枝和竹梢的热解过程可以看出,毛竹采伐剩余物组分从156 ℃开始热解,与竹秆的热解过程对比,并参照毛竹硫酸盐法制浆时[26]的工艺条件,选定毛竹采伐剩余物制浆时蒸煮温度为0~170 ℃,防止选取更高的温度导致纤维素在碱水解时剥皮反应剧烈而纸浆强度下降[27]。

-

根据对毛竹采伐剩余物竹枝、竹梢的化学成分、纤维形态等信息,参照其他竹材蒸煮工艺参数,经初步探究后,确定了以下打浆工艺:料液比m(料):V(液)=1:4,蒸煮最高温度为170 ℃,用碱量为200.0 g·L-1的氢氧化钠,打浆度51 °SR。蒸煮实验结果及浆料物理性质:毛竹采伐剩余物制得的竹浆卡伯值为31.10,残碱量为27.60%(相对于加入量),pH 12.2,筛渣率为2.20%,粗浆得率为44.71%,比细浆得率高2.00%,介于德宏州巨龙竹Dendrocalamus sinicus(粗浆得率44.00%)和金平龙竹Dendrocalamus peculiaris(粗浆得率45.26%)之间[28-29],但是卡伯值比这2种竹种高,与针叶木浆差不多(一般针叶木未漂白浆卡伯值达30以上[29]),说明毛竹采伐剩余物的纸浆比其他竹种竹浆较硬,这也是为什么后期其打浆度较高的原因。

-

纸张的物理性能是多因素综合作用的结果。原料纤维长度的大小与纸张抗涨性能、耐破度和撕裂指数等性能指标直接相关,而纤维长宽比的大小直接影响了纸张的撕裂强度、交织性、柔韧性等性能。如表 4所示:毛竹采伐剩余物打浆度普遍比其他几种高,这可能是因为毛竹采伐剩余物的抽出物和灰分比较高,而且其纤维平均长度较其他几种较短,增加了打浆难度。而成浆纸片抗张指数和耐破指数分别为63.88 N·m-1·g-1,4.14 kPa·m-2·g-1,都达到漂白硫酸盐竹浆质量规定的优等品级别(抗张指数>58.00 N·m-1·g-1,耐破指数>4.00 kPa·m-2·g-1),虽然撕裂指数(6.96 mN·m-2·g-1)不是很高,但也达到了一级漂白硫酸盐竹浆质量规定(>6.50 mN·m-2·g-1)。对比其他竹种物理性能,毛竹采伐剩余物所制得纸片的抗张指数、耐破指数均大于巨龙竹和龙竹,这可能是毛竹采伐剩余物的半纤维素质量分数高,使得打浆时细纤维化程度提高,增加了纤维间的结合力,增加了纸张强度,但稍低于木浆和毛竹竹秆的抗张指数和耐破指数。毛竹采伐剩余物的撕裂指数较低,这可能是毛竹采伐剩余物的纤维属于短粗纤维的原因。

2.1. 化学成分分析

2.2. 半纤维素中多糖分析

2.3. 纤维形态分析

2.4. 毛竹采伐剩余物FT-IR分析

2.5. 热重分析

2.6. 制浆性能分析

2.7. 手抄纸片性能分析

-

毛竹采伐剩余物竹枝、竹梢的主要化学成分均为纤维素、半纤维素及木质素,各部位主成分的化学结构与毛竹竹秆部位的竹材相似。毛竹采伐剩余物半纤维素主要由木糖、阿拉伯糖和糖醛酸组成,竹枝、竹梢半纤维素各个组分质量分数相差不大,其中鼠李糖、半乳糖、阿拉伯糖质量分数竹梢均比竹枝稍低。纤维长度和长宽比,均是竹秆>竹梢>竹枝,竹秆、竹梢、竹枝纤维平均长度分别为1 643.66,1 030.7和948.54 μm,长宽比分别为123.12,64.70和65.55,其次竹梢和竹枝纤维主要分布在400~2 000 μm,而竹秆主要分布在1 500~2 500 μm。毛竹采伐剩余物竹枝、竹梢的热分解过程与毛竹竹秆相似,热分解温度不同。热分解过程主要发生在第2阶段,毛竹采伐剩余物竹枝、竹梢的最大热分解温度分别为341和339 ℃,与毛竹竹秆相比,毛竹采伐剩余物具有较好的热稳定性。毛竹采伐剩余物经硫酸盐法成浆后,纸浆得率为44.71%,有良好的成浆性能,有较高的抗张强度和耐破强度,比巨龙竹和龙竹要优良,可作为纸浆材使用。

DownLoad:

DownLoad: