-

竹材作为可持续的生物质资源,具有生长迅速、可再生、碳汇能力强等优点,符合绿色发展的时代要求[1−2]。作为高质化应用形式,展平竹是指竹筒或弧形竹片经软化、展平、干燥、定型制成的片状材料,能够使中空结构的竹材平板化,提高竹质板材原材料利用率,拓展竹质板材的应用领域。现有竹材展平技术在环保、低能耗的同时,还能做到快速软化,并且已从刻痕展平逐渐发展到无刻痕展平[3−5],板材质量和价值显著提升,为后续开发应用提供了更多可能。依赖工业化的无刻痕竹展平技术,可将展平竹刨切成具有一定幅面的片状材料,极大地拓展了展平竹材的应用范围,展平竹已从家具用材向家居用材转化。

根据材料刨切单板可分为竹集成材刨切单板、重组竹刨切单板和展平竹刨切单板。与传统竹集成材刨切单板相比,展平竹刨切单板在保留竹材天然纹理的同时,还具备无胶的环保属性。目前,刨切单板以刨切竹集成材为主,研究集中于应用设计和生产加工[6],在附加性能方面也存在一定理论研究。展平竹目前集中于应用研究,如展平竹单板、复合材料和胶合板等性能研究[7−9],对于展平竹刨切单板的研究处于工艺优化阶段[10]。在展平竹制备过程中水热环境会影响后续材料的理化性能[11],刨切工艺对单板表面质量和力学性能有显著影响[12−14]。同时由于竹材径向上梯度结构差异[15],导致展平竹不同位置刨切下的单板物理力学性能存在差异。综上所述,梯度位置和处理工艺决定了展平竹刨切单板性能,会影响单板后续的生产成型与应用形式。因此,本研究以不同径向位置的展平竹刨切单板为对象,研究刨切方式、水煮处理对展平竹刨切单板结构和性能影响,以期为后续单板生产利用提供数据支撑。

-

4~6年生毛竹Phyllostachys edulis,采自中国福建省南平市,由福建龙竹科技集团股份有限公司加工。取离地1.1 m,长1.5 m,壁厚11.5 mm的基部竹材作为原料,经剖分、软化、去青去黄、展平、刨切(横向刨切/纵向刨切)形成0.4 mm厚的单板。将部分单板经80~90 ℃水煮清洗60 min,再统一进行干燥。

纵向刨切的单板经水煮清洗编号为ZS,横向刨切的单板经水煮清洗编号为HS,横向刨切的单板未经水煮清洗编号为HW (表1)。将刨切后的单板按照从竹黄到竹青的顺序,挑选等距的单板,分别编为1、2、3、4、5号。其中,纵向刨切材料因受刨切设备限制,有效刨切范围仅为横向刨切材料的一半,故挑选等距的3片单板。

单板编号 径向位置(竹黄到竹青) 第1层 第2层 第3层 第4层 第5层 ZS ZS-1 ZS-2 ZS-3 − − HS HS-1 HS-2 HS-3 HS-4 HS-5 HW HW-1 HW-2 HW-3 HW-4 HW-5 说明: “−”表示未制备该径向位置的试样。 Table 1. Sample number diagram

-

通过电子显微镜(SZM45T-LCD8)和扫描电子显微镜(Quanta 200)对水煮和未水煮的、不同刨切方向的、不同径向位置的刨切单板的表面形貌、纤维和薄壁细胞形态进行观察,探究表面质量的差异。

-

将单板制备成25 mm×25 mm的试样,径向位置(1~5号)的ZS、HS、HW试样制备6组对照样(每组至少2个平行样)。按照GB/T 1578—1995《竹材物理力学性能实验方法》,测量试样不同梯度结构、不同刨切方向、不同处理方式的单板密度的变化情况,其中包括基本密度、绝干密度、12%含水率(气干)时的密度。

-

将单板制备成800 mm×25 mm的试样,每片单板制备2个平行样,径向位置(1~5号)的ZS、HS、HW试样各准备6组对照样(每组至少2个平行样)。按照GB/T 18318.1—2009《纺织品弯曲性能的测定 斜面法》,测量试样的抗弯刚度。每个试样测量两端和正反的弯曲长度,共4次,求取平均弯曲长度、抗弯刚度及变异系数,根据弯曲长度和单位面积质量计算抗弯刚度。

根据公式分别计算2个方向的平均单位宽度的抗弯刚度,精确至0.001 mN·cm:$G=m\times {C}^{3}\times {10}^{-3}。 $其中:G为单位宽度的抗弯刚度 (mN·cm);m为试样的单位面积质量(g·m−3);C为试样的平均弯曲长度(cm)。

-

将单板制备成180 mm×15 mm的试样,径向位置(1~5号)的ZS、HS、HW试样各准备6组对照样(每组至少3个平行样)。按照GB/T 12914—2018《纸和纸板抗张强度的测定》制样,取材料节间部位180 mm作为试样,使夹持距离为150 mm。将试样按照25 mm·min−1的速度拉伸,使其在5~30 s内断裂。根据有效样计算材料的拉伸性能。

-

将不同径向位置(1~5号)的HS单板样品粉碎,使用X射线衍射仪(Ultima Ⅳ)检测样品的纤维素晶型以及结晶度。以粉末形式平铺于玻璃样品托上,每个样品制备3个试样。X射线衍射仪以5°~35°,10°·min−1的速度,用CuKα (λ=1.540 6 Å)辐射源测量纤维素晶体结构,并且根据Segal公式计算相对结晶度。

-

将不同径向位置(1~5号)的HS试样粉碎制备为竹粉,并进行绝干处理。根据美国可再生能源实验室(NERL)方法,用配备有Aminex HPX-87H柱(300 mm×7.8 mm)和折射率(RI)检测器的液相色谱仪(ICD-3000),并使用1260系统分析纤维和薄壁细胞中糖的质量分数,获得纤维素和半纤维素的质量分数。通过紫外分光光度计,用205 nm波长测得酸溶木质素的质量分数,用马弗炉测得酸不溶木质素的质量分数,最终得出木质素的质量分数。通过计算分析纤维素、半纤维素、木质素的质量分数,分析不同径向位置HS单板化学成分的差异。

-

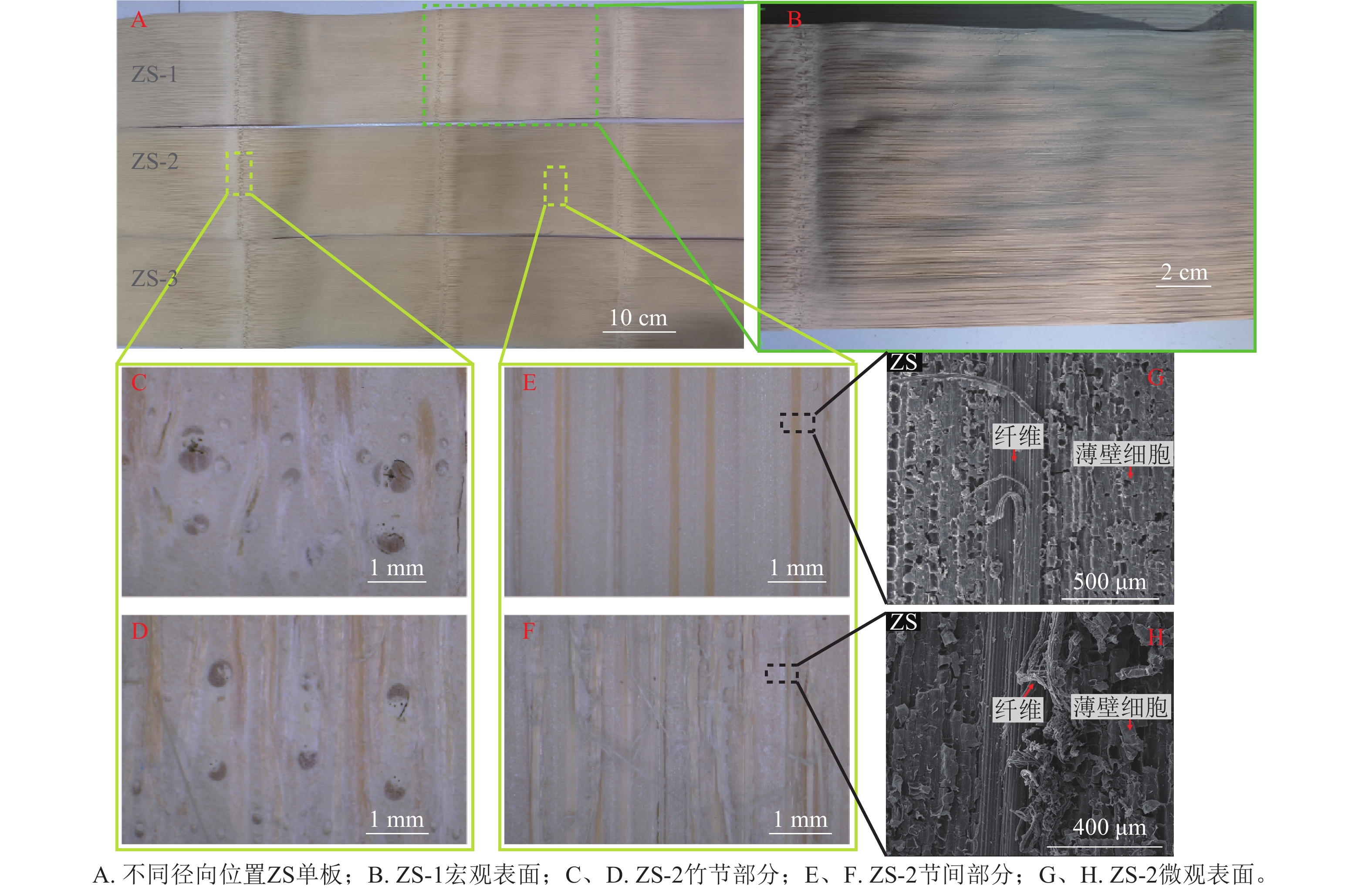

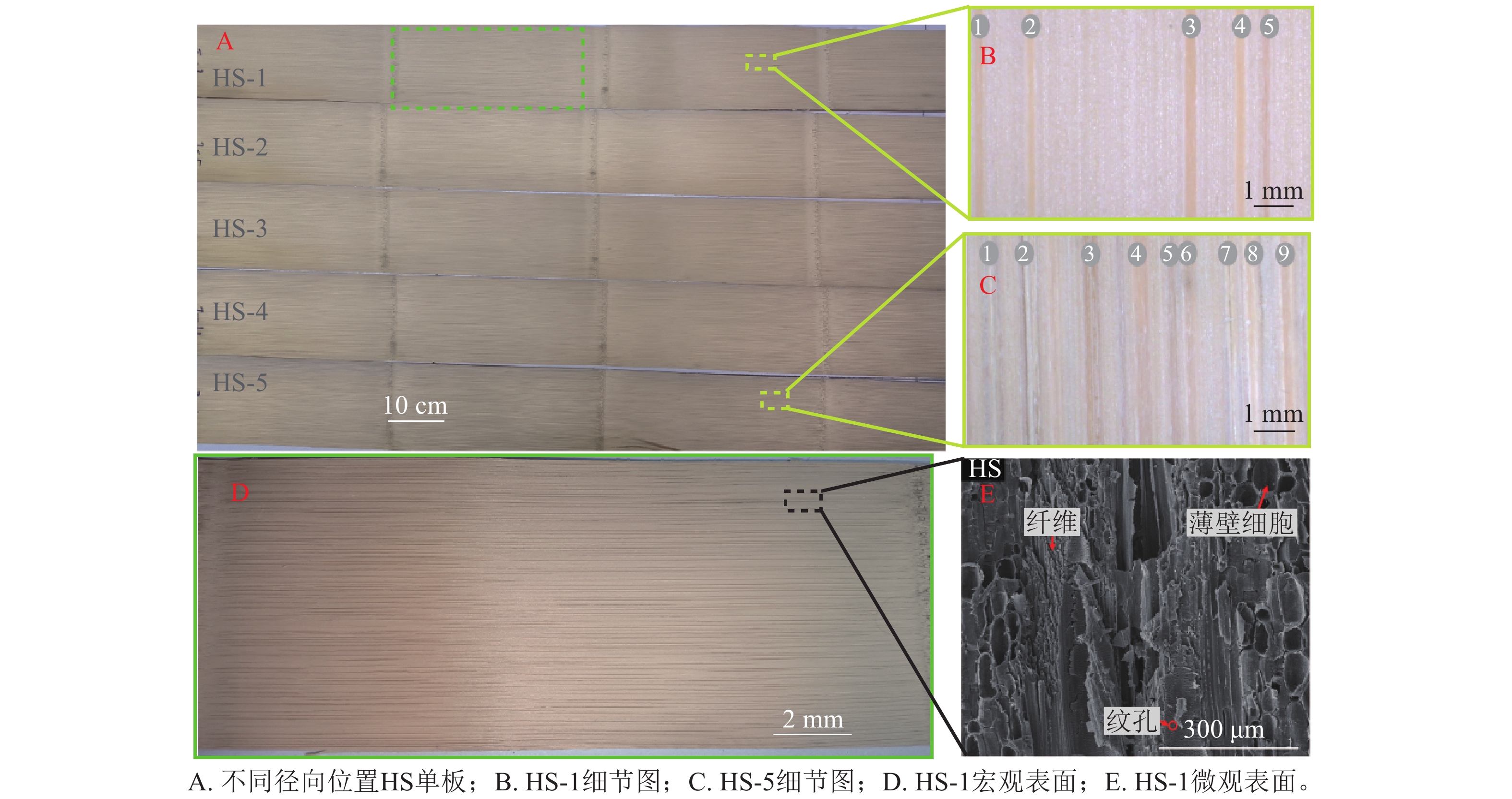

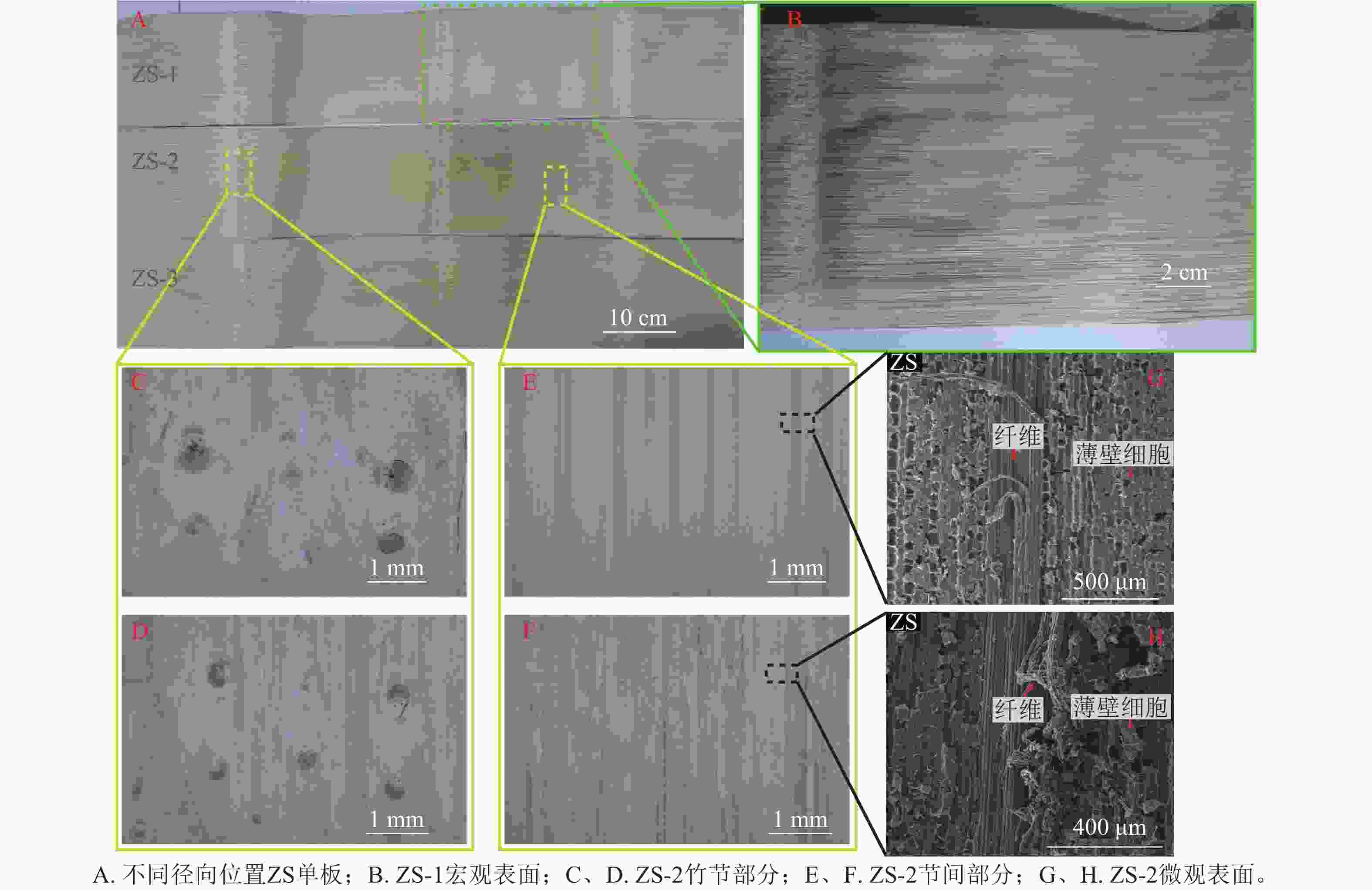

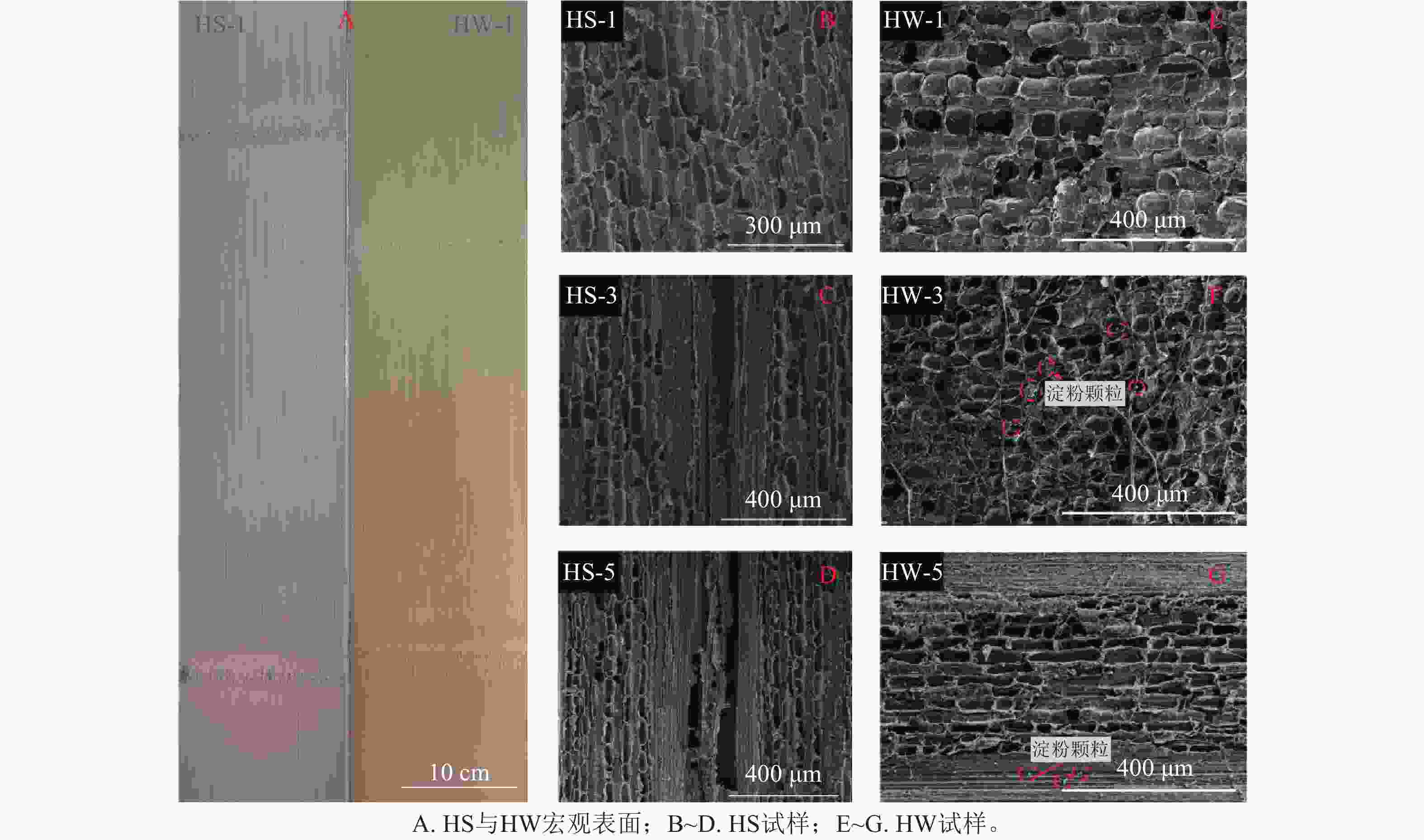

横向刨切(HS)单板可以观察到竹黄侧维管束少(图1A~C),表面更光洁平整(图1B);横向刨切竹青侧维管束数量较多(图1C),出现表面质量问题的概率变大。横向刨切刀具与竹材纤维走向形成一定夹角,且依赖薄木刨切机较小的刃倾角,刨切时纤维基本不会出现提前劈裂现象[16],薄壁细胞部分受起翘纤维影响较小,通常表面平整光滑(图1D、E)。

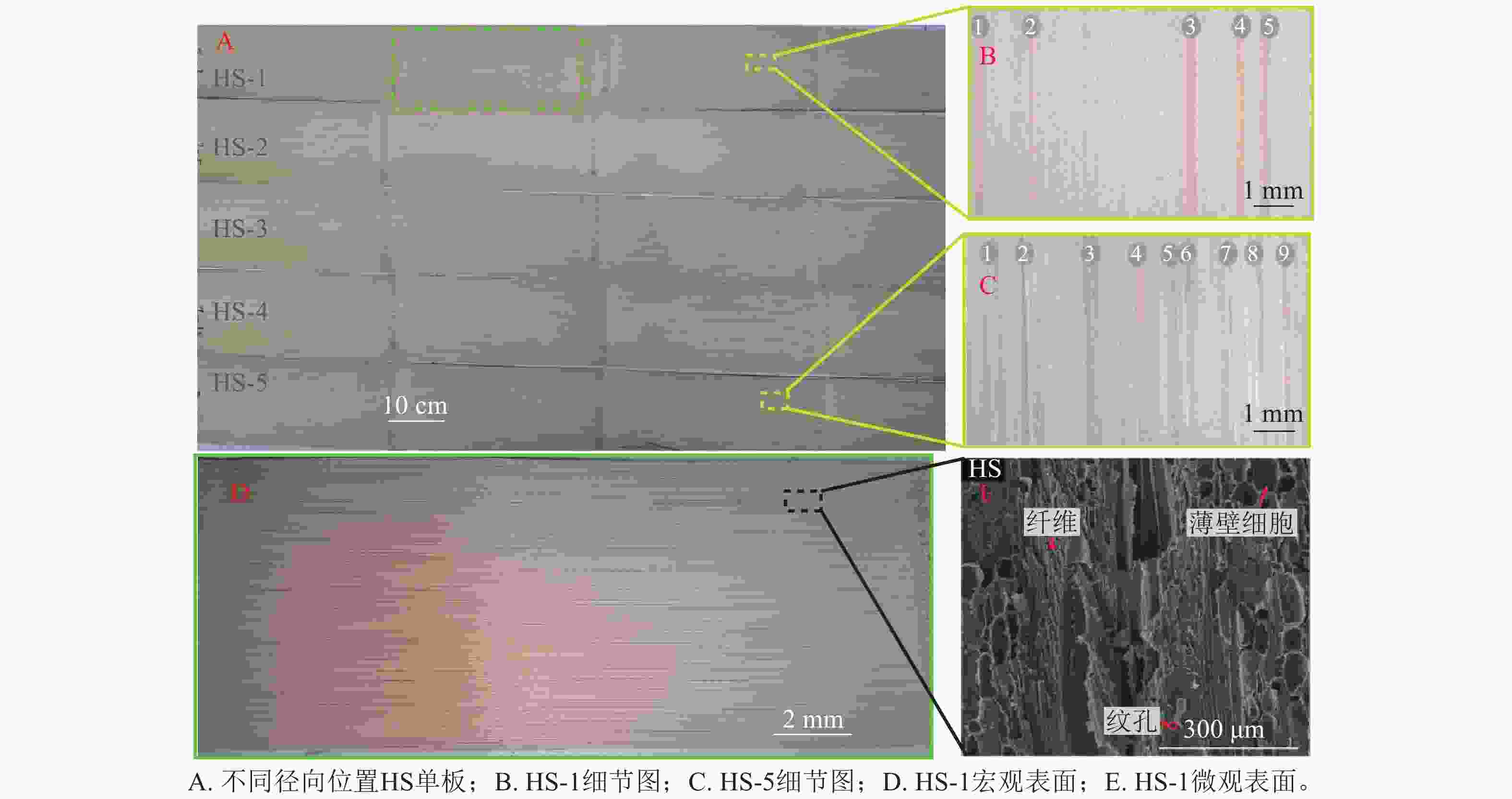

与横向刨切对比,纵向刨切(ZS)单板的表面质量较差,出现更多纤维毛刺,且不同径向位置单板表面质量不稳定(图2A、B)。一方面,纵向刨切因刨切方向与纤维走向平行,部分纤维在未被刀具切断时提前劈裂被破坏,提前劈裂的纤维不仅对维管束区域刨切质量造成影响,引起纤维的翘起和毛刺现象,同时会影响周围薄壁组织的刨切质量和材料的光泽感等。另一方面,刀具的精度对于纵向刨切单板的表面效果影响较大,刀具使用次数过多或竹材靠近竹青部分硬度的提升,增加了刨切难度,容易造成刨切质量不佳,影响刨切质量的稳定性和光泽度。

不同刨切方向竹节部分的材料较节间部分表现出良好的刨切质量及其稳定性(图2C~H),较少有小毛刺等缺陷。维管束纵横交错的结构使其在纵向刨切时较节间部分更少出现纤维起翘现象,横向刨切在竹节和节间部分基本没有表面质量差异。

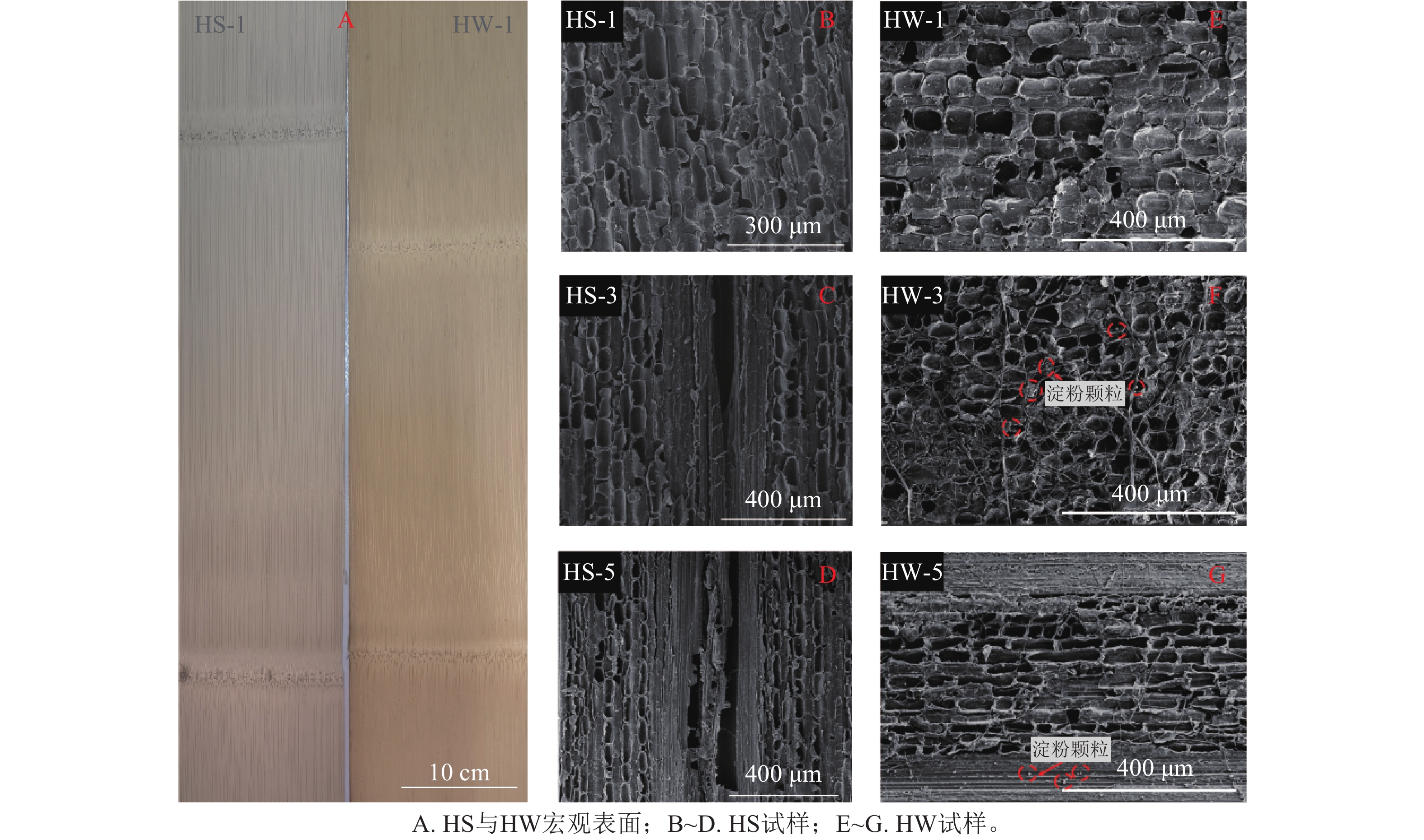

水煮清洗工艺对单板表面质量影响相对较小,但单板颜色有一定程度的改变。具体表现为经过水煮工艺处理后的单板颜色会变浅(图3A),同时去除单板薄壁细胞内残留淀粉颗粒(图3B~G)。软化工序对弧形竹片中的淀粉颗粒有一定影响,但未完全清除。通过80~90 ℃的水浴清洗60 min,充分去除内部淀粉残留,有效地提高了竹材的防霉性能[17−18]。同时,未水煮清洗的单板表面有部分因横向刨切断裂产生的细小纤维影响薄壁细胞部分的表面光泽,对比横向刨切水煮单板的表面,预处理很好地解决了这部分影响表面质量的因素。

-

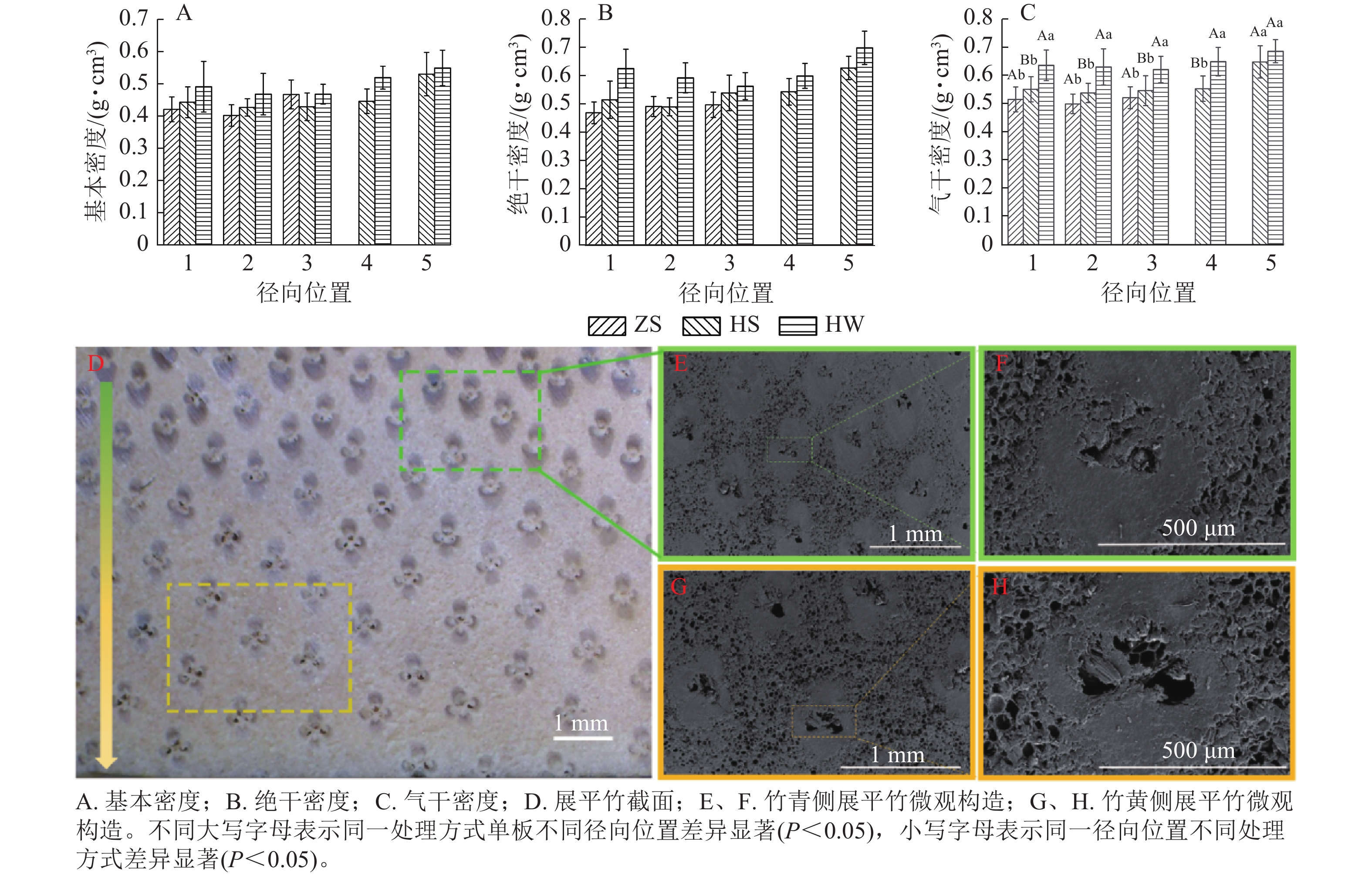

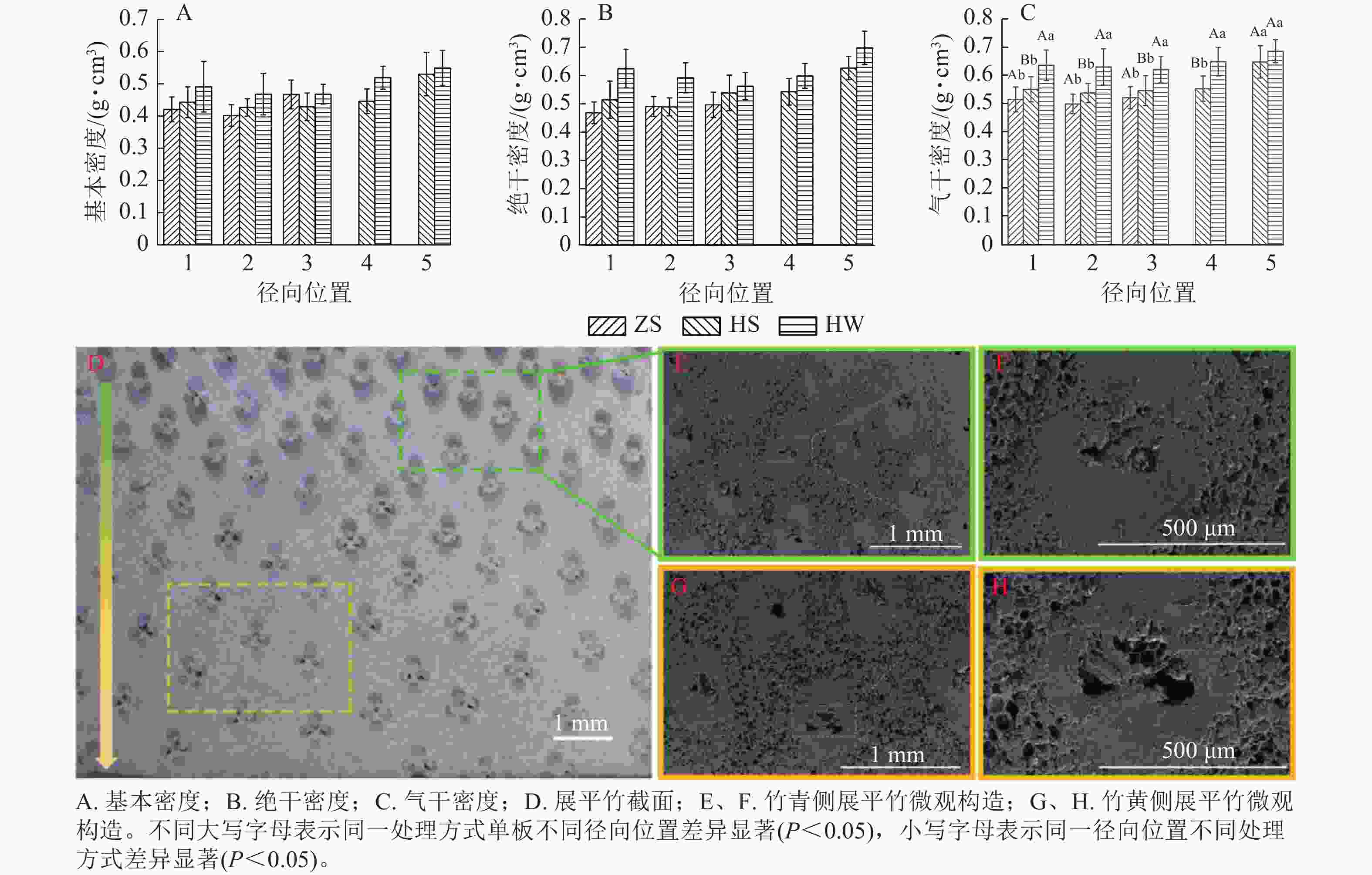

单板密度从竹黄到竹青先稍微减小再增加(图4A~C),竹壁同一径向位置刨切下的单板中,HW试样的密度最大,HS试样密度减小约11.03%,ZS试样密度减小约16.93%。展平竹刨切单板的基材展平竹,是将弧形竹片无刻痕展平,在展平过程中材料有一定致密化(图4D)。弧形竹片靠近竹黄部分的材料维管束大而稀疏、孔隙较大,在展平过程中竹黄部分受压严重,靠近竹黄部分基本组织受压致密化程度大于竹青部分(图E~H)[19−21],竹肉中密度更均匀化,靠近竹黄部分和竹肉中部差异不显著,HS试样竹青侧单板密度较其他部位差异显著(P<0.05)。水煮清洗和刨切方向对于密度的梯度变化规律基本没有影响,水煮清洗会去除部分淀粉颗粒,使材料密度较HW试样显著降低(P<0.05)。纵向刨切与横向刨切试样的密度有差异,但差异不显著,纵向刨切对表面质量的影响更大,厚度尺寸误差更大,同时纵向刨切造成的木毛现象可能导致厚度测量偏大,是纵向刨切(ZS)单板密度小于横向刨切(HS)单板的主要原因。

-

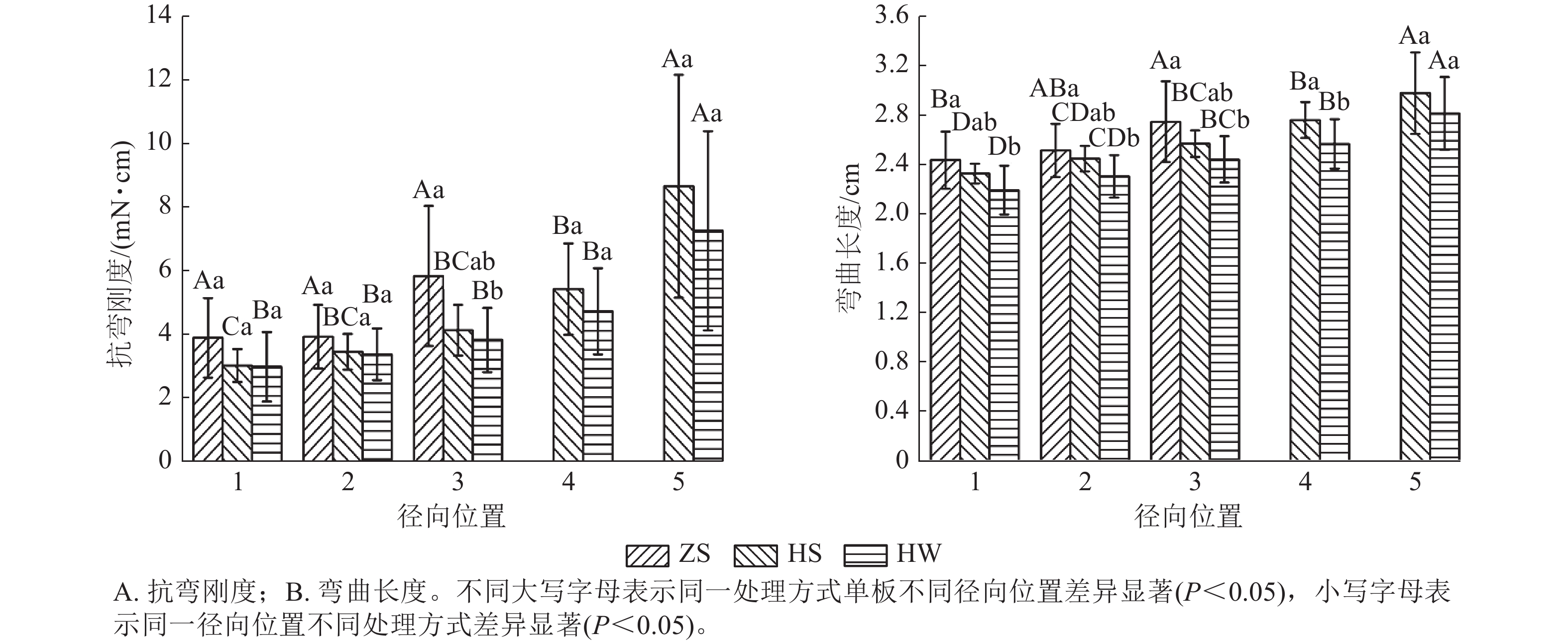

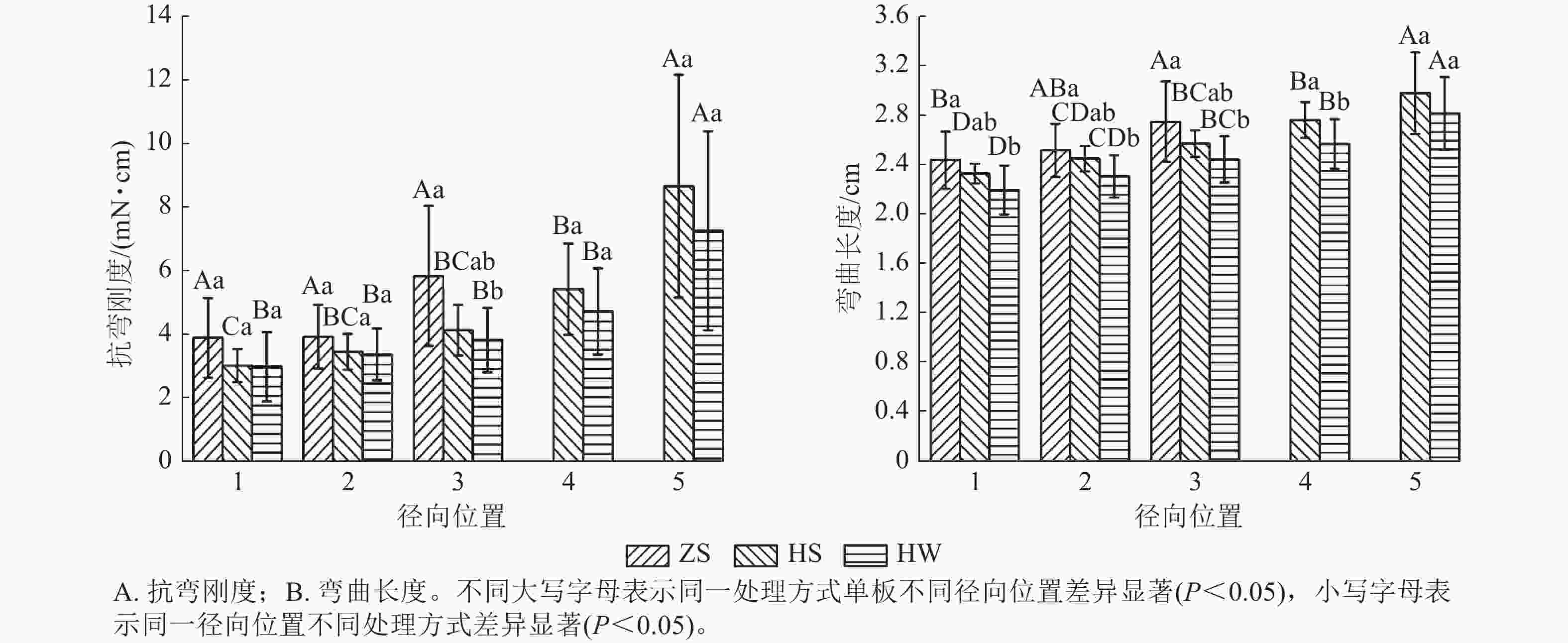

展平竹壁从竹黄到竹青,抗弯刚度呈递增趋势,HW试样的抗弯刚度最小,HS试样比HW试样增加约11.47%,ZS试样抗弯刚度比HW试样增加约34.22% (图5A)。抗弯刚度越大,柔韧性越差。纵向刨切材料抗弯刚度较横向刨切材料更大,柔韧性差,特别是竹肉中部差异较大(P<0.05);水煮清洗处理对于柔韧性起负面作用,经水煮清洗的横向刨切单板在同一梯度位置抗弯刚度增加约11.47%,但差异不显著。竹材从竹黄到竹青,纤维束逐渐变小而密集,纤维体积分数增加,薄壁细胞占比减少,材料弯曲变形空间减小,柔韧性逐渐变差[22−23]。刨切方向带来柔韧性的差异,可能是纵向刨切更多保留纤维的完整性,弯曲时应力在纤维上传递,容易应力集中,柔韧性较横向刨切更差。抗弯刚度与单位面积质量和弯曲长度成正比,受展平工序影响竹黄侧密度相对大于竹肉中部,竹黄侧抗弯刚度差异不如弯曲长度差异明显(图5)。

-

对于横向刨切单板(HW、HS),抗拉强度从竹黄到竹青呈现逐步增加的趋势(P<0.05),HS试样从70.3 MPa增加到128.7 MPa,HW试样从63.2 MPa增加到115.0 MPa;纵向刨切单板(ZS)的抗拉强度随梯度变化的递增趋势不显著(表2)。维管束是竹材力学性能的主要来源[24],越靠竹青侧的单板维管束占比增加,故竹青侧的单板抗拉强度更高,抗拉强度呈梯度变化。ZS在维管束逐渐密集时抗拉强度有所降低,可能是因为增加的毛刺现象使拉伸时主要提供强度的有效体积减小。

试材 不同径向位置抗拉强度/MPa 1 2 3 4 5 ZS 80.3±22.3 Aa 94.1±30.1 Aa 92.1±23.4 Aa − − HS 70.3±18.1 Cab 77.9±22.5 Cab 86.9±25.4 BCa 105.8±28.3 ABa 128.7±52.9 Aa HW 63.2±14.4 Cb 71.7±16.6 BCb 76.5±18.2 BCa 91.2±28.9 Ba 115.0±45.3 Aa 说明:“−”表示无此项。不同大写字母表示同一处理方式单板不同径向位置差异显著(P<0.05),小写字母表示同一径向位置不同处理方式差异显著(P<0.05)。 Table 2. Tensile strength

同一梯度位置,ZS的抗拉强度最高,HS较ZS降低约11.78%,HW较ZS降低约20.68% (表2),在靠近竹黄侧差异显著(P<0.05)。一方面,水煮预处理可能促进纤维素分子链的重新排列,形成更多结晶区域,提高了材料的拉伸性能。另一方面,刨切方向对于材料抗拉强度的影响,可能是纵向刨切更好地保留了纤维的连续性,因此ZS较HS的强度更高。此外,同一片材不同位置的抗拉强度受纤维分布、刀具等影响会有一定差异。

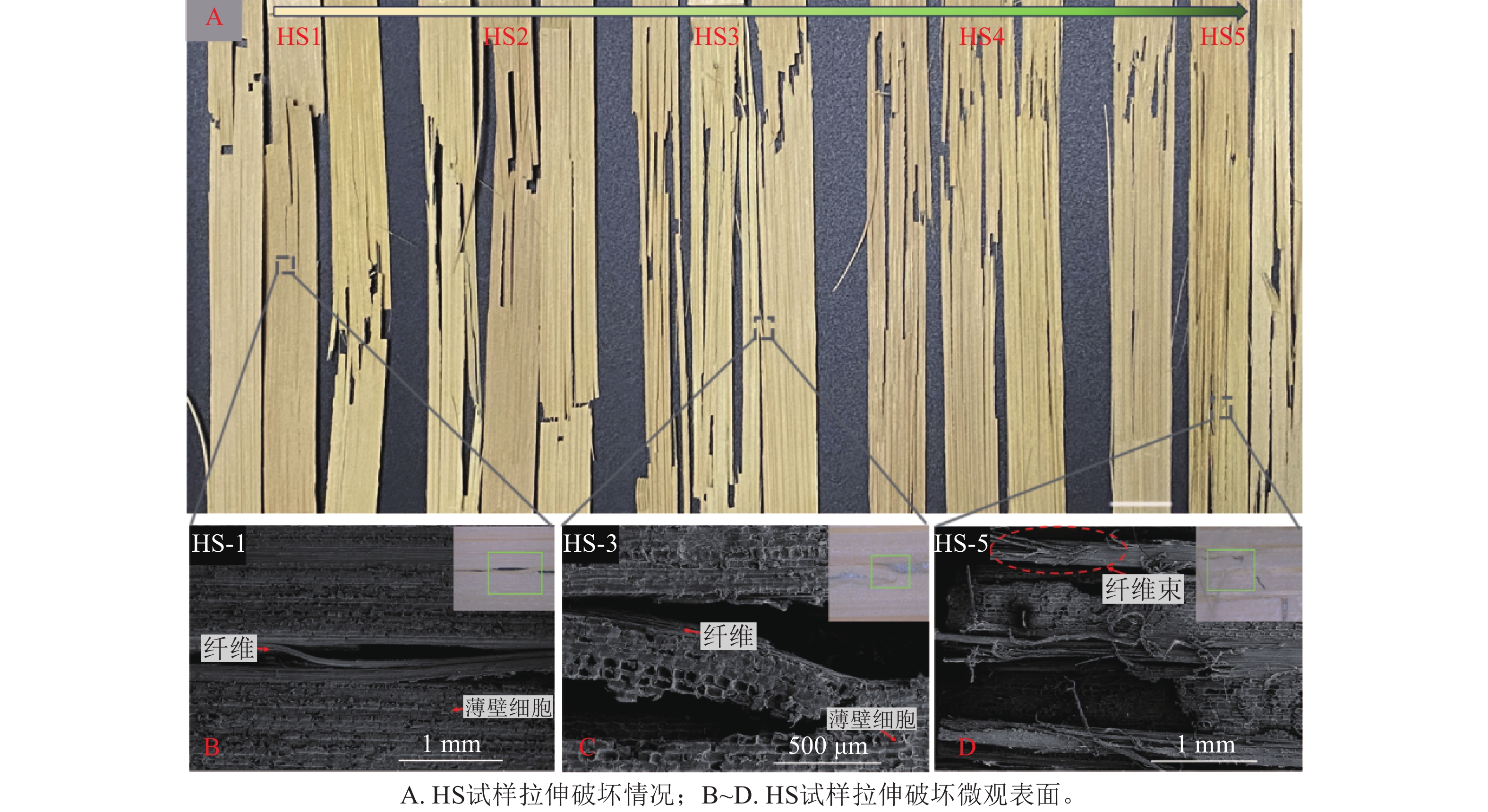

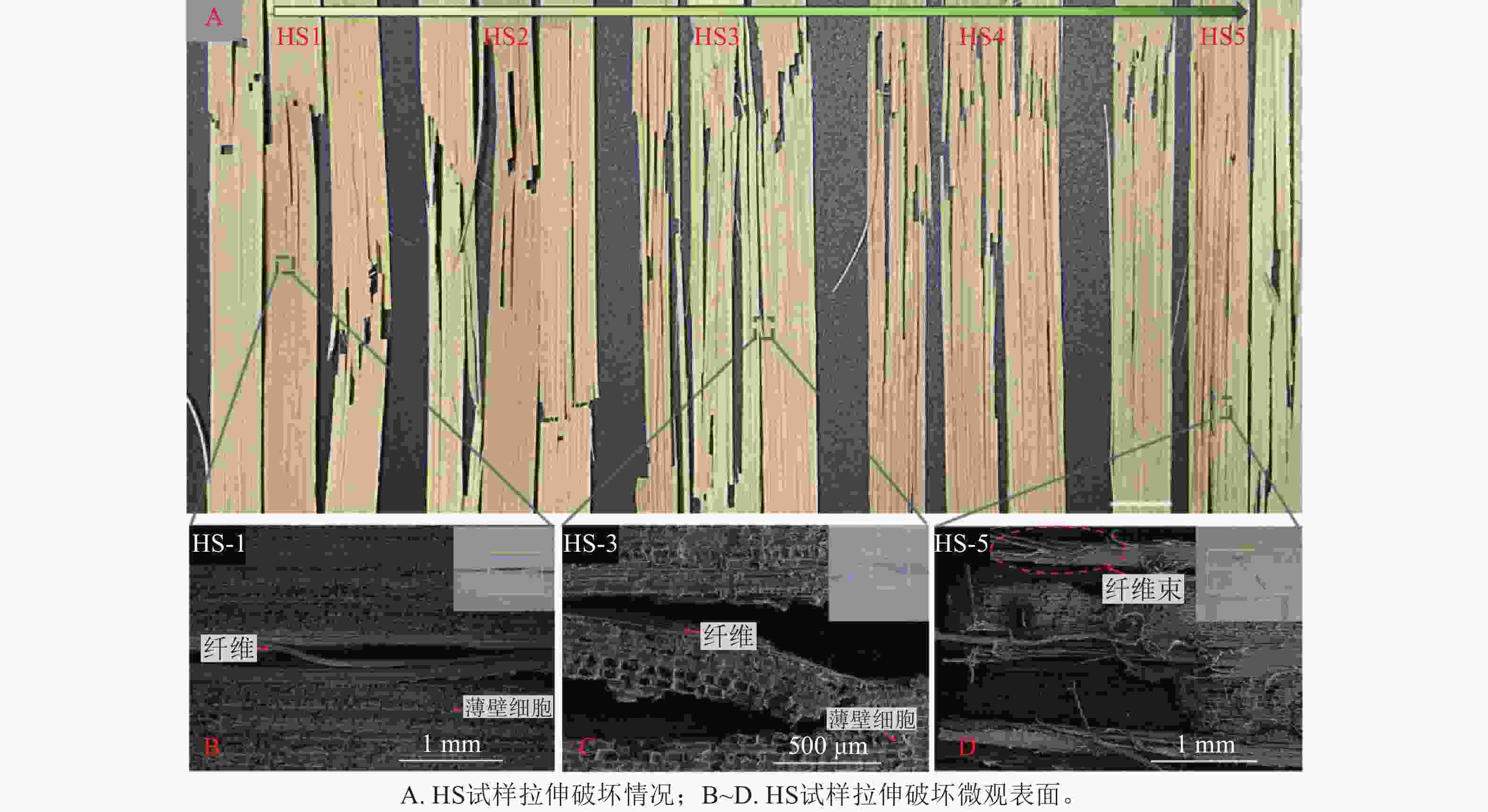

从竹黄到竹青,单板拉伸破坏形态逐渐从脆性断裂到韧性断裂,靠近竹青部分维管束更紧密,常见纤维的撕裂,拉伸裂纹更少集中在同一水平位置,破坏形态更多是“W”形(图6A)。拉伸造成的破坏分布在材料的弱界面。维管束受刀具影响较大时,被破坏处表现为裂纹沿着纤维方向延伸(图6B);在维管束连续性较好的位置被破坏处可能沿着纤维和薄壁细胞的界面以及在强度较低的薄壁细胞中延伸(图6C);在维管束较为完整紧实时,大多是在薄壁细胞处被破坏以及表现为纤维的拔出(图6D)。在靠近竹黄部分,维管束较为疏松且薄壁细胞占比更多,单板基本在同一水平高度断裂。靠近竹青部分维管束更紧实,受拉应力时维管束通常呈现整束拔出的状态,同时维管束占比较多,因此裂纹整体大多呈现极致的“W”形。

-

短时间的软化处理可能对于竹片中不同径向位置材料的影响程度不同,化学成分规律性变化不明显(表3)。半纤维素从竹黄到竹青先增加再减小,软化的湿热环境使HS-1的半纤维素降解更明显,较中部半纤维素质量分数有所降低。竹材纤维中纤维素、酸不溶木质素质量分数高于薄壁细胞,而薄壁细胞中半纤维素和酸溶木质素质量分数较高[25]。饱和蒸汽条件下,半纤维素中的乙酰基降解为乙酸,对纤维素稳定性造成影响[26],同时纤维占比更多的部分纤维素质量分数更高,在不同梯度结构和不同程度半纤维素降解的影响耦合作用下,不同径向位置的HS试样纤维素质量分数分布规律不明显。酸溶木质素基本呈现减小趋势,归因于单板随梯度结构变化薄壁细胞占比减小。HS-1至HS-5纤维质量分数逐渐增加,木质素质量分数从28.36%增加到29.87%;HS-1木质素质量分数较竹肉中部有一定上升,可能是软化导致HS-1的半纤维素降解明显,HS-1木质素质量分数更高。

样品编号 纤维素/% 半纤维素/% 木质素/% 酸不溶木质素/% 酸溶木质素/% HS-1 41.17 20.90 28.36 25.98 2.38 HS-2 41.50 22.00 27.04 24.79 2.25 HS-3 41.45 21.74 27.47 25.26 2.21 HS-4 40.04 21.78 27.31 25.15 2.16 HS-5 40.67 18.49 29.87 27.73 2.14 Table 3. Chemical composition content of HS samples

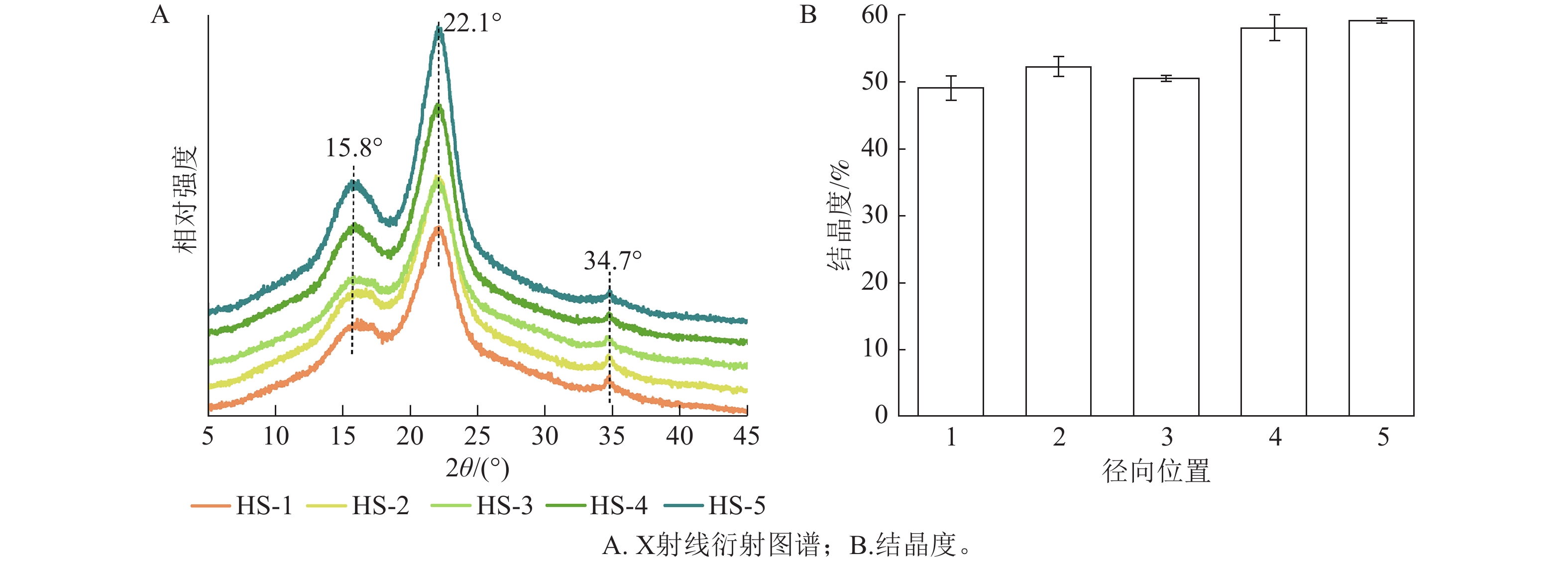

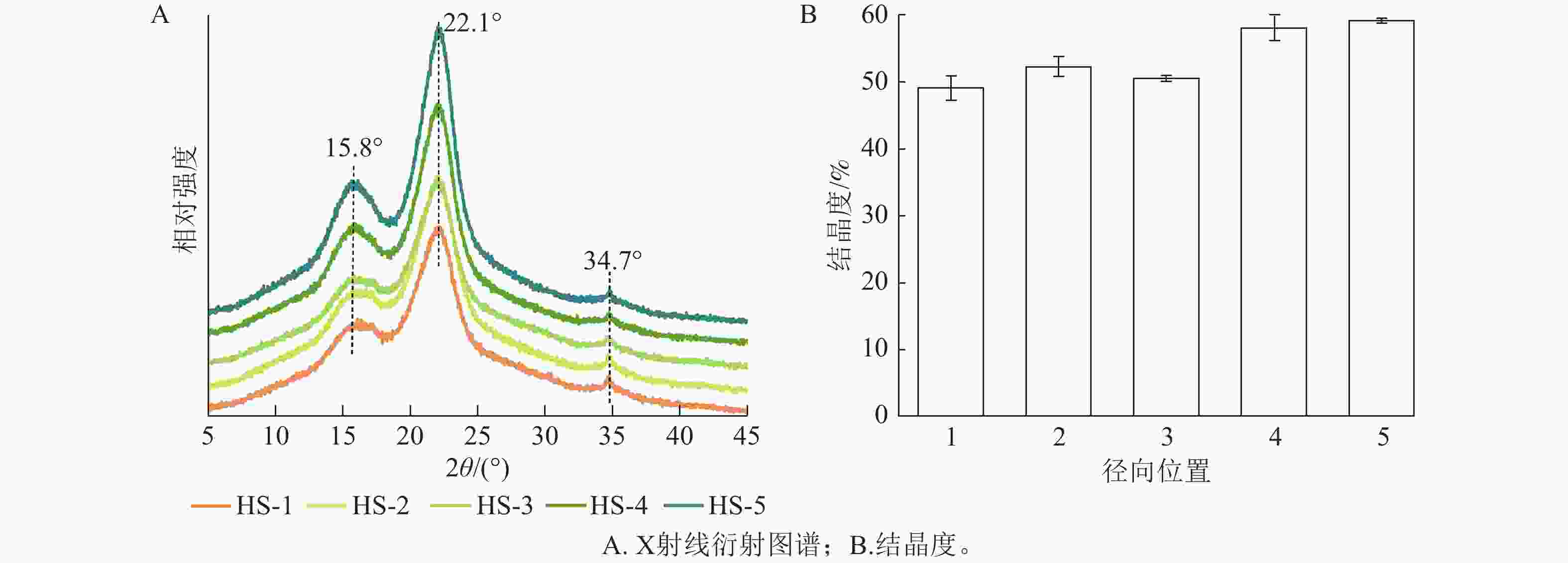

不同梯度结构单板的X射线衍射(XRD)图谱和结晶度(Cr I值)如图7所示。生产工艺未改变材料的纤维素晶型,从竹黄到竹青的单板结晶度在上升趋势中有一部分降低。单板的(1-10) / (110)、(200)和(004)晶面衍射峰分别位于15.8°、22.1°和34.7°附近,表明经软化等生产工序的不同径向位置单板中纤维素的晶型为典型的纤维素Ⅰ型。从竹黄到竹青,单板的结晶度整体呈现上升趋势,因为纤维的结晶度远大于薄壁细胞,纤维占比从竹黄到竹青逐渐增加[27−28]。中部的结晶度小于靠近竹黄部分的结晶度,可能是因为受软化工序影响较大的竹黄部分半纤维素相对含量减少,干燥后形成更紧密的氢键网络,结晶度相对上升。

-

本研究以展平竹刨切单板为研究对象,研究不同刨切方式和水煮处理下不同径向位置单板的理化性能差异,以期定向协调材料性能优势。主要结论如下:①在物理性能方面,刨切方式对单板表面质量影响最大。横向刨切效果更优且具有质量稳定性,纵向刨切受径向位置影响,竹青侧刨切难度增加。竹展平板密度均质化明显,竹黄侧和竹肉中部差异较小,水煮处理使单板密度平均降低约11.03%。②在力学性能方面,水煮处理和纵向刨切对拉伸性能起积极作用,单板从竹黄到竹青拉伸性能逐步递增;水煮处理和纵向刨切对柔韧性起消极作用,单板从竹黄到竹青柔韧性呈递减趋势。③在化学成分方面,展平竹生产工序使不同径向位置材料化学成分变化略微不同,不改变纤维素晶型。从竹黄到竹青结晶度基本呈现递增趋势,竹肉中部有一定下降。

Influence of cutting methods and pretreatment on the structure and performance of sliced bamboo veneers

doi: 10.11833/j.issn.2095-0756.20250370

- Received Date: 2025-07-08

- Accepted Date: 2025-11-21

- Rev Recd Date: 2025-11-16

-

Key words:

- sliced bamboo /

- radial position /

- planing method /

- water-boiling pretreatment /

- physical and chemical properties

Abstract:

| Citation: | LIU Xuan, HUANG Bin, CHEN Hong, et al. Influence of cutting methods and pretreatment on the structure and performance of sliced bamboo veneers[J]. Journal of Zhejiang A&F University, 2026, 43(2): 1−10 doi: 10.11833/j.issn.2095-0756.20250370 |

DownLoad:

DownLoad: