-

防腐处理可以提高木材抗真菌、抗虫等性能[1],使木材免受生物危害,从而延长木材的使用年限,是减少木材使用量和延长木材储碳周期的重要途径[2]。木材防腐行业经过几十年的发展取得了显著进步,目前逐渐朝着对人和环境友好的方向发展,有机防腐剂因具有高效、环保的优点而成为研究热点[3−6]。多数有机防腐剂来源于工业和农用杀菌剂,嘧菌酯(azoxystrobin)是一种低毒、高效、广谱的杀菌剂,它对非靶标生物安全,具有环境相容性好的优点[7−8]。嘧菌酯用于木竹材保护[4, 9]的研究表明:嘧菌酯对木材腐朽菌表现出较优的抑制效果,载药量为0.22~0.44 kg·m−3的防腐处理辐射松Pinus radiata 在腐朽菌侵染后的质量损失率均小于8%,且嘧菌酯对串珠镰刀菌Fusarium moniliforme和可可球二孢Botryodiplodia theobromae等木竹材霉变菌具有较好的防治效果;同时,嘧菌酯和有机碘化合物复配(质量分数为0.1%)对竹材霉菌的防治效率在90%以上[10],因此可作为新型木材防腐剂进行开发利用。良好的抗流失性能是防腐木材保持较长耐久性的重要因素[11−14],因此进行嘧菌酯处理木材的抗流失性能研究非常必要。

防腐材中防腐剂流失率测试的关键在于准确分析其含量。嘧菌酯检测可采用气相色谱(GC)和高效液相色谱(HPLC)分析方法[15],HPLC分析方法因具有使用条件便捷、定量准确度高的优点成为常用的分析方法[16−17]。木材存在丰富的抽提物,处理材流失液中抽提物的色谱峰可能会对HPLC分析嘧菌酯造成干扰,所以检测处理材流失液中的嘧菌酯,需要建立一种准确、快捷的分析方法。鉴于此,本研究建立了嘧菌酯的HPLC分析方法,并对方法精准性进行评价。同时制备了嘧菌酯水基化制剂,探究水基化制剂和乙醇溶解药剂处理材抗流失性能差异;选择马尾松Pinus massoniana、杉木Cunninghamia lanceolata和107杨Populus×euramericana为处理材研究对象,探究树种类型和药剂质量分数对处理材中嘧菌酯抗流失性能的影响,旨在为嘧菌酯的户外使用提供研究基础。

-

马尾松产自广西派阳山林场,树龄为38 a,气干密度为0.70 g·cm−3,含水率为8.2%;杉木产自湖南,树龄为23 a,气干密度为0.37 g·cm−3,含水率为9.2%;107杨产自山东,树龄为15 a,气干密度为0.44 g·cm−3,含水率为8.0%。选取无明显节子、年轮分布均匀的边材作为试验用材,锯切制成规格为20 mm × 20 mm × 20 mm (纵向×弦向×径向)的试件。

药剂主要为甲醇(色谱纯)和嘧菌酯(有效成分≥98%,白色粉末),其他试剂均为分析纯。

-

前期研究发现:质量分数为0.040%~0.056%的嘧菌酯处理木材(载药量为0.31~0.44 kg·m−3),室内耐腐效果较优[4]。考虑户外处理木材的使用条件不同,本研究流失试验药剂质量分数设置为0.05%和0.15%共2个水平。

-

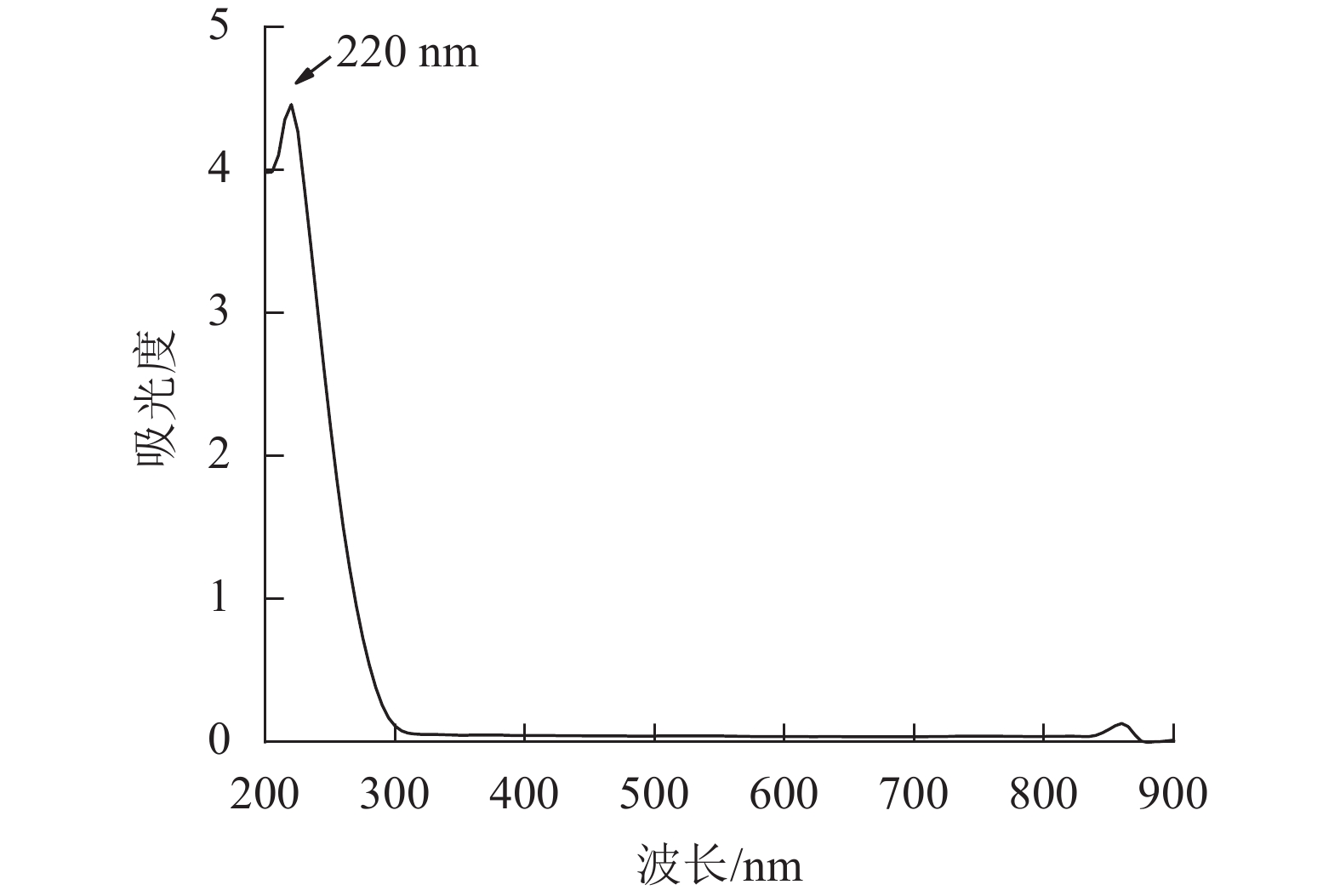

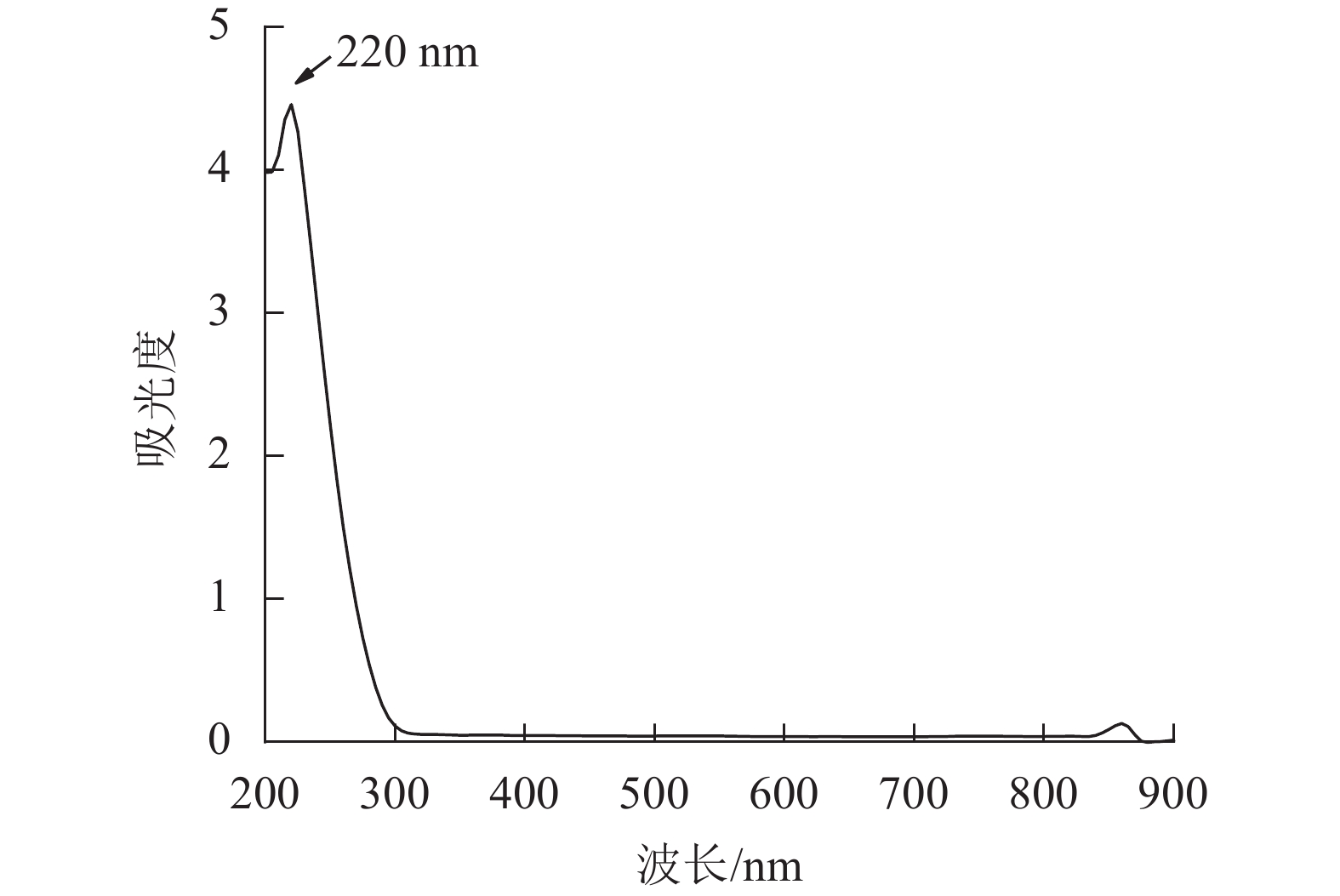

使用Elite P230高效液相色谱仪、UV230+紫外-可见光检测器等仪器,在参考文献[15−17]的基础上,结合本研究各种木材的抽提物分离条件,确定如下色谱条件:依利特Supersil ODS2 C18色谱柱为250.0 mm×4.6 mm,5 μm;柱温为30 ℃;V(甲醇)∶V(水)=80∶20为流动相;流速为0.8 mL·min−1;检测波长为220 nm;进样量为20 μL;保留时间约6.1 min。

-

准确称取0.050 0 g的嘧菌酯标准品,置于50 mL容量瓶中,加入少量甲醇使之溶解,用甲醇稀释至刻度,摇匀;移取上述溶液2 mL,用甲醇和水(体积比为80∶20)的混合溶剂定容至10 mL,配制成200 mg·L−1的标准溶液,再用上述混合溶剂稀释,配得质量浓度为80、40、20、5、1 mg·L−1的嘧菌酯系列标准溶液,在上述色谱条件下进样分析,绘制标准曲线。

-

①嘧菌酯制剂。参考张景朋等[9]的方法,称取1.00 g嘧菌酯原药于25 mL锥形瓶中,缓慢加入1.00 g乙腈和3.00 g乙酸乙酯,在45 ℃下搅拌溶解,依次加入3.00 g乳化剂、2.00 g蒸馏水,充分搅拌后得质量分数为10%的嘧菌酯制剂。选用苯乙烯基苯酚聚氧乙烯醚和辛基酚聚氧乙烯醚为乳化剂,分别制备A1和A2共2种制剂,使用建立的HPLC分析方法对制剂的质量分数进行分析。2种制剂均分别用水稀释200倍、67倍得到质量分数为0.05%和0.15%的防腐工作液。②嘧菌酯乙醇溶液。称取1.00 g嘧菌酯原药,加入9.00 g乙醇溶解,搅拌均匀后得质量分数为10%的嘧菌酯乙醇溶液。使用乙醇稀释分别配置成质量分数为0.05%和0.15%的防腐工作液。

-

防腐处理参照GB/T 29905—2013《木材防腐剂流失率试验方法》进行[18]。处理前将试件进行编号、称量(精确至0.01 g),将试件放入500 mL烧杯中,用重物压稳,注入防腐处理液,置于真空干燥箱中,抽真空至−0.09 MPa,保持10 min,卸压后常压浸泡5 min。处理完毕后取出试件,用滤纸擦去表面残留药液,称取处理后质量(精确至0.01 g),于常温下气干至含水率小于20%。

试件中嘧菌酯总质量计算公式为:m=(m2-m1) ×c×1 000。其中:m为试件中嘧菌酯的总质量(mg);m1为试件处理前质量(g);m2为试件处理后质量(g);c为防腐液中嘧菌酯的质量分数(%)。

-

流失试验参照GB/T 29905—2013《木材防腐剂流失率试验方法》进行[18]。将相同处理条件的6块试样作为1组,置于500 mL烧杯中,加入180 mL蒸馏水,试样浸没在蒸馏水液面以下,用磁力搅拌器搅拌,在6、24、48 h时更换1次蒸馏水,之后每隔48 h更换1次蒸馏水,共计14 d。收集每次更换的滤出液,合并后用于质量浓度分析。

分别取各组收集的流失液50 mL,用旋转蒸发器除水后,加入适量色谱甲醇和蒸馏水混合溶剂充分溶解,经0.45 μm聚四氟乙烯膜过滤后用于HPLC分析。采用外标法,根据1.2.2绘制的标准曲线和HPLC色谱图面积计算流失液中嘧菌酯质量浓度,流失液分析进行3次重复,计算平均值。

嘧菌酯流失率计算公式为:L = kv/m × 100%。其中:L为防腐剂的流失率(%);k为流失液中待测成分的质量浓度(mg·L−1);v为流失液的体积(L);m为试件中嘧菌酯总质量(mg)。

-

将甲醇溶解的嘧菌酯标准溶液放置于石英比色皿,以甲醇作为空白样,采用紫外-可见光分光光度计,测定嘧菌酯标准溶液在波长190~900 nm下的吸光度。得到嘧菌酯的全波长扫描图(图1),发现嘧菌酯的吸收峰在220 nm处获得较高的灵敏度,因此本研究选择220 nm作为检测波长。

-

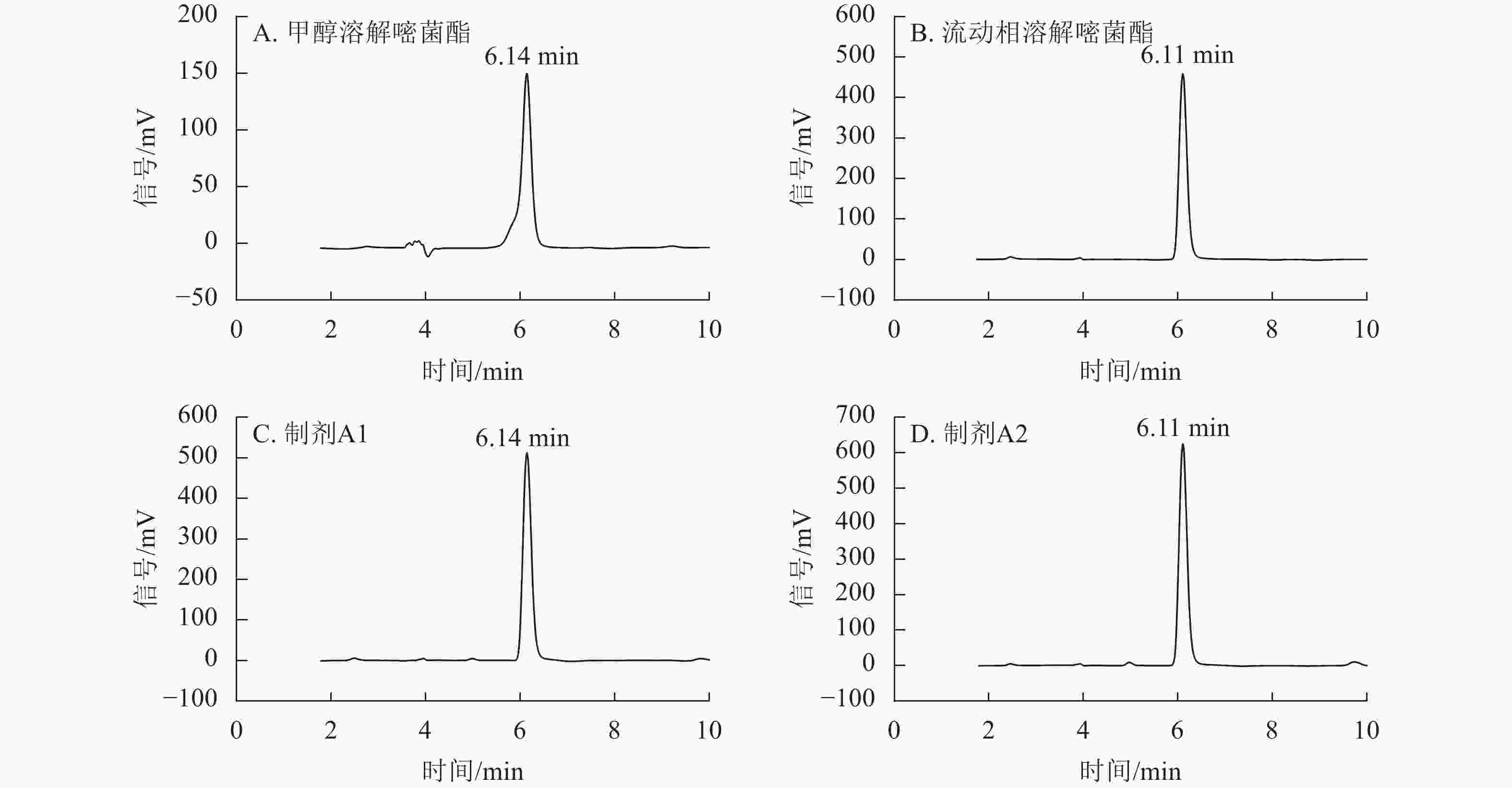

木材抽提物色谱峰一般出峰时间较早[19],分析条件要首先保证抽提物色谱峰和嘧菌酯色谱峰完全分开,同时能使嘧菌酯较早出峰,可以节省分析时间。采用V(甲醇)∶V(水)=80∶20为流动相,流速为0.8 mL·min−1的分析条件。从图2A可见:甲醇溶解的嘧菌酯标准溶液的色谱图中,基线较稳,保留时间为6.14 min,无拖尾,但是出现前沿峰。前沿峰的出现会造成定量分析准确性下降,这一般是由于样品溶剂的洗脱能力大大强于流动相或者柱效能下降造成的[20]。此处可能是使用了甲醇溶解嘧菌酯,因为甲醇洗脱能力强于流动相造成前沿峰的出现。如图2B所示:流动相溶解嘧菌酯进样分析的色谱图中,前沿峰消失,峰形对称,保留时间为6.11 min,同时用流动相溶解稀释制剂A1和A2进行分析,发现除了嘧菌酯色谱峰外,无其他辅助成分的干扰峰(图2C和2D),可实现嘧菌酯的准确分析。

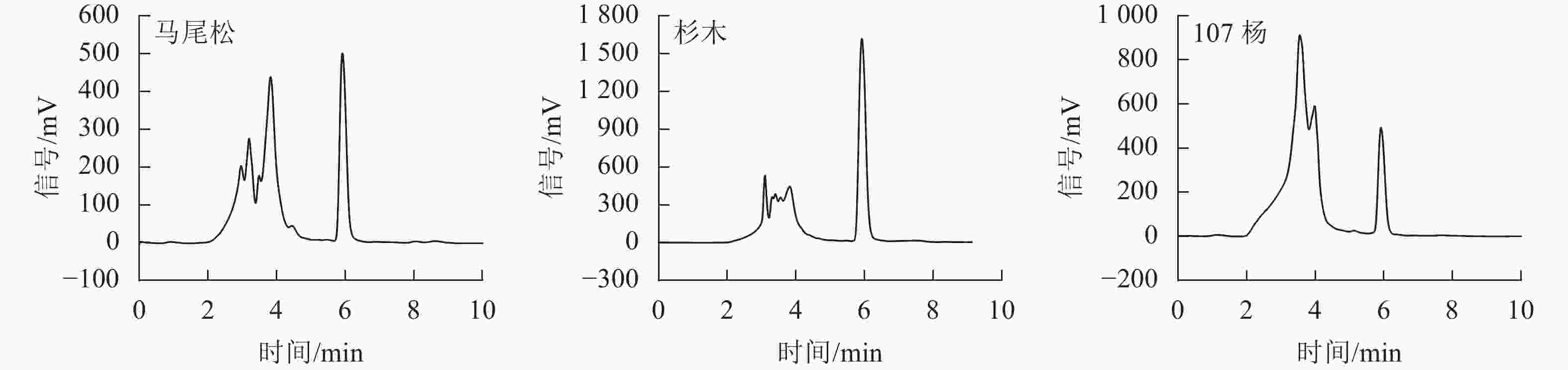

此外,检测流失液中的嘧菌酯质量浓度,需确保木材抽提物的色谱峰对嘧菌酯色谱峰定量分析无影响。将马尾松、杉木和107杨防腐处理材的流失液进行液相分析(图3)可见:3种处理材流失液的高效液相色谱图中,虽然不同木材的抽提物种类不同,但是3种木材总抽提物的色谱峰均在5 min之前出峰完成,对嘧菌酯定量分析无干扰,所以此色谱条件能实现对流失液中嘧菌酯的准确分析。

-

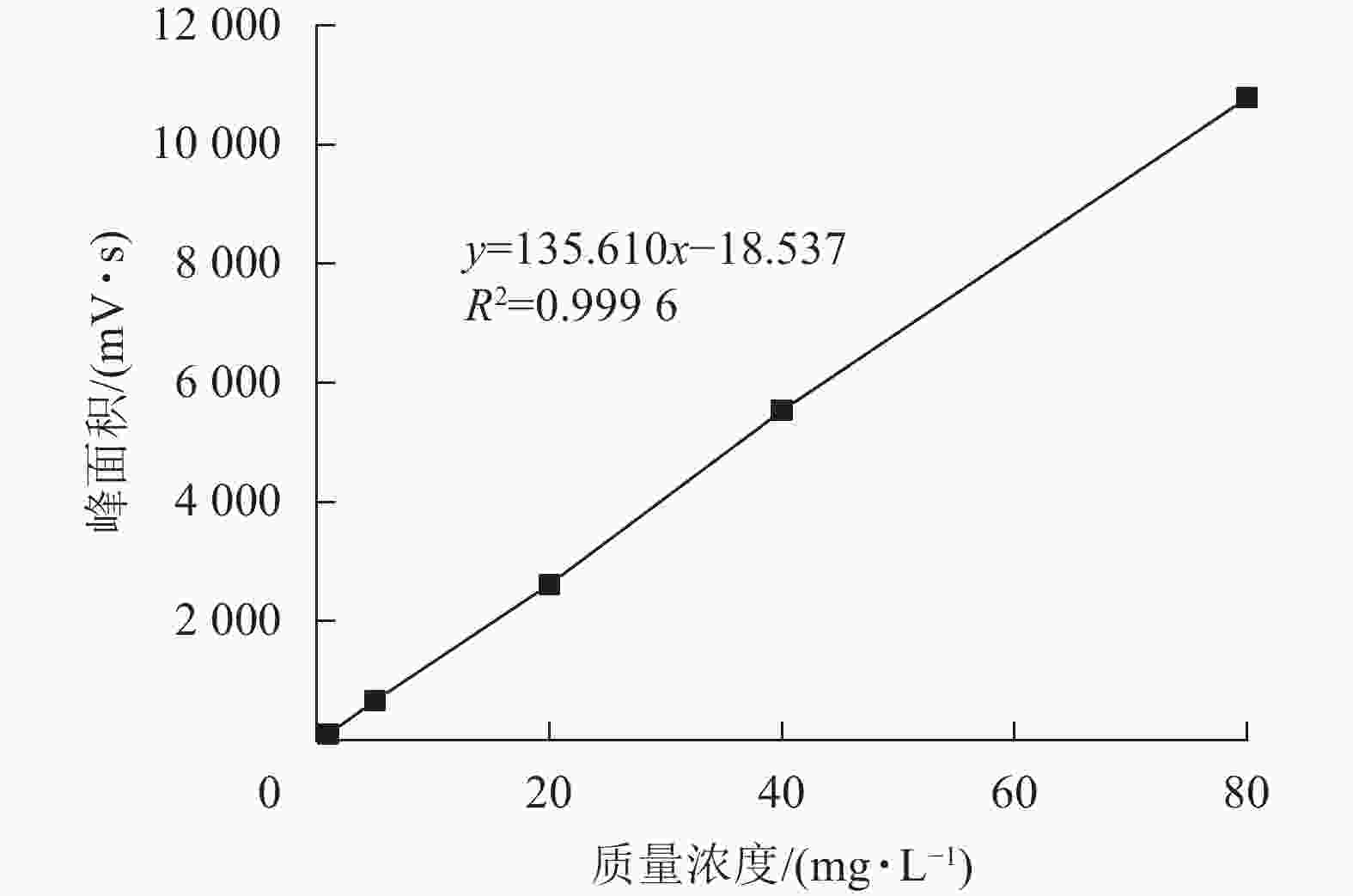

在1.2.1的色谱条件下,对不同质量浓度的嘧菌酯标准溶液进行测定,以质量浓度(x,mg·L−1)为横坐标,峰面积(y)为纵坐标,绘制标准曲线如图4。在嘧菌酯为1~80 mg·L−1时,得到线性方程为y=135.610x −18.537,决定系数(R2)=0.999 6,线性相关性强。

-

准确称取0.106 0 g制剂A1,置于20 mL容量瓶中,用流动相溶解并定容至刻度,摇匀,再将此溶液用流动相稀释10倍,制得待分析样品,取6份平行试样进行HPLC分析;准确称取0.111 2 g的制剂A2,进行上述相同操作。从表1可见:制剂A1中嘧菌酯的平均质量分数为10.15%,标准偏差为0.06%,变异系数为0.59%;制剂A2中嘧菌酯的平均质量分数为10.13%,标准偏差为0.05%,变异系数为0.45%。表明平行分析结果之间数据非常接近,分析方法精密度高。

表 1 精密度试验结果

Table 1. Precision test results

试样 平行试样质量分数/% 标准偏差/% 变异系数/% 1 2 3 4 5 6 平均值 制剂A1 10.06 10.17 10.13 10.23 10.20 10.12 10.15 0.06 0.59 制剂A2 10.17 10.18 10.11 10.09 10.07 10.15 10.13 0.05 0.45 -

在空白溶液和已知质量浓度的嘧菌酯样品中分别添加不同质量浓度的嘧菌酯标准品,配成一定质量浓度的样品溶液,在上述色谱条件下进行分析,计算回收率。从表2可见:嘧菌酯的回收率为98.2%~100.4%,平均回收率为99.7%,表明该方法准确度较高。综上所述,该分析方法标准曲线线性相关性好,精密度及准确度较高,可应用于有效成分嘧菌酯质量分数的分析。

表 2 准确度试验结果

Table 2. Accuracy recovery test results

试样

编号本底值/

(mg·L−1)加入标样量/

(mg·L−1)理论值/

(mg·L−1)实测值/

(mg·L−1)回收率/

%1 0 10 10.00 9.82 98.2 2 0 20 20.00 19.94 99.7 3 0 40 40.00 39.66 99.1 4 28.16 10 38.16 38.24 100.2 5 28.16 20 48.16 48.28 100.3 6 28.16 40 68.16 68.42 100.4 -

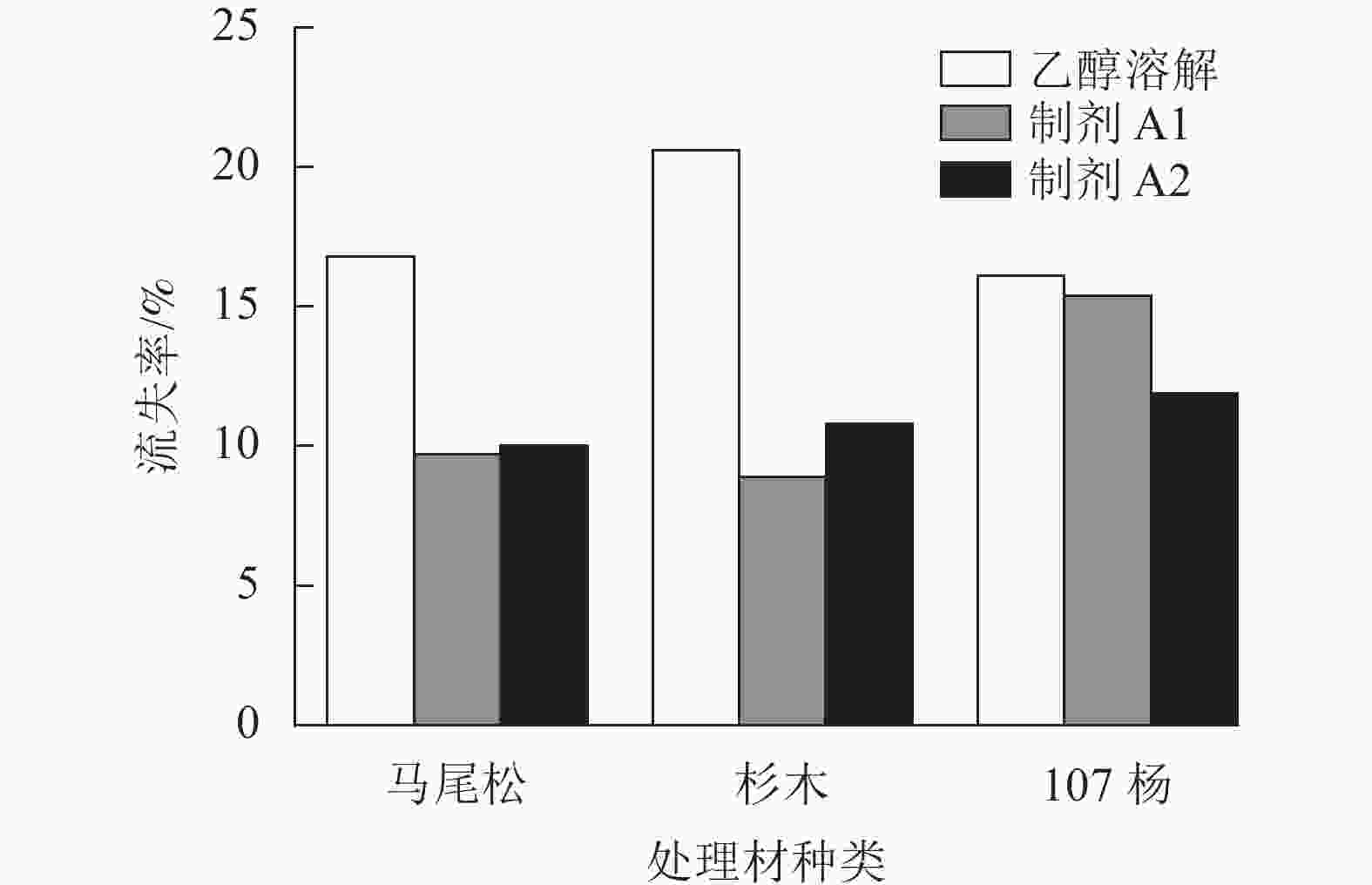

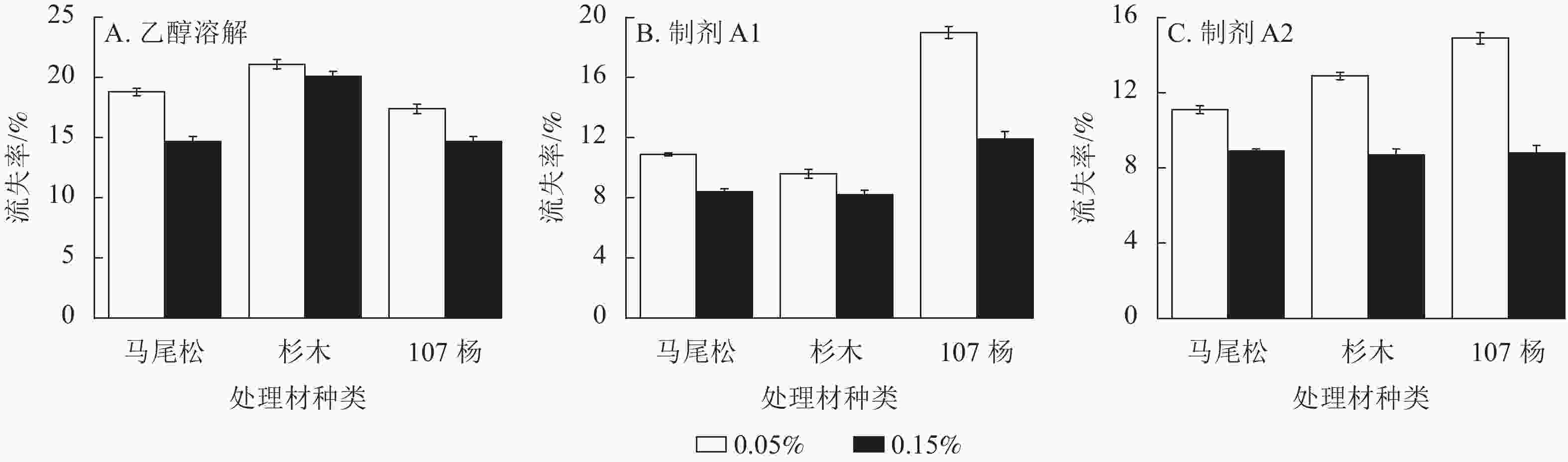

从图5A可见:乙醇溶解嘧菌酯溶液的处理材中,嘧菌酯的抗流失性较好,各处理材中嘧菌酯的流失率相对较低,即防腐剂在处理材中的固着性能较好。具体地,在质量分数为0.05%和0.15%的药剂处理下,马尾松嘧菌酯的流失率分别为18.8%和14.7%,107杨嘧菌酯的流失率分别为17.4%和14.7%,杉木嘧菌酯的流失率分别为21.0%和20.1%。表明嘧菌酯在马尾松和107杨中的流失率水平相当,而杉木的高于马尾松和107杨。

图 5 质量分数为0.05%和0.15%的药剂下嘧菌酯3种制剂处理木材的流失率

Figure 5. Leaching rates of treated wood by 3 formulations of azoxystrobin with content of 0.05% and 0.15%

如图5B所示:嘧菌酯制剂A1的处理材中,嘧菌酯的流失率均小于20.0%,抗流失性能较优。马尾松和杉木处理材的流失率分别为8.4%~10.9%和8.2%~9.6%,两者均低于107杨处理材的流失率(11.9%~19.0%)。

如图5C所示:嘧菌酯制剂A2的处理材中,嘧菌酯的流失率均小于15%,抗流失性能较强。在质量分数为0.05%的药剂处理下,马尾松、杉木和107杨处理材的流失率分别为11.1%、12.9%和14.9%,3种处理材差异不大;在质量分数为0.15%的药剂处理下,马尾松、杉木和107杨3种处理材的流失率分别8.9%、8.7%和8.8%,3种处理材基本相同。

嘧菌酯3种制剂的处理表现出同样的流失规律,3种不同树种均为低质量分数制剂处理材的流失率大于高质量分数制剂处理材。2种不同质量分数制剂处理材的药剂流失量基本一致,而防腐液质量分数较高时处理材载药量较高,造成药剂流失量占载药量的比例更低。而木材种类对流失率的影响在每种制剂中的表现没有明确规律,只有在制剂A1的处理材中,107杨流失率明显高于马尾松和杉木,另外2种制剂处理材在不同树种之间的流失率差别较小。

-

为了比较嘧菌酯制剂和乙醇溶液处理木材流失率的差异,以质量分数为0.05%和0.15%的制剂处理下流失率的平均值作为嘧菌酯在此树种上的流失率。如图6所示:乙醇溶解、制剂A1和制剂A2处理的107杨药剂流失率非常接近,但以制剂A2处理材稍低;对马尾松和杉木而言,乙醇溶解嘧菌酯处理材的药剂流失率高于制剂A1和制剂A2。表明将嘧菌酯制备成水基化制剂处理木材不会造成流失率的升高,可用于处理户外木材及其制品。

-

有研究认为:有机防腐药剂处理木材的流失性能主要与其在水中的溶解度相关[21],嘧菌酯在水中溶解度为6 mg·L−1(20 ℃)[22],而醚菌酯在水中的溶解度仅为2 mg·L−1(20 ℃),醚菌酯在水中极小的溶解度可能是各处理材中醚菌酯流失率均较小的原因。醚菌酯是甲氧基丙烯酸酯的另一代表化合物,其处理马尾松、107杨等木材的药剂流失率为3.1%~18.4%[23],而本研究处理木材嘧菌酯的流失率为8.7%~21.0%,可见,醚菌酯抗流失性能优于嘧菌酯。三唑类化合物是已被广泛应用的有机木材防腐剂,关于其抗流失性能已有较多研究,其中戊唑醇和丙环唑制剂处理马尾松防腐材的流失率分别为28.0%~41.0%和18.0%~26.0%,环丙唑醇等其他三唑化合物流失率高达34.0%~43.0%[24],嘧菌酯抗流失性能明显高于三唑类化合物,这可能与三唑化合物在水中的溶解度高达31~110 mg·L−1(20 ℃)有关[21]。此外,通过三唑化合物和铜复配制剂处理木材可增加三唑固着性能,或者三唑制剂中添加疏水剂处理木材可减少水中溶解防腐剂的量,这2种方法均可降低处理材中三唑化合物的流失率[24]。如果嘧菌酯等制剂处理材用于水流失严重的环境区域,亦可考虑进行上述处理进一步降低其流失率。

然而,木材防腐剂流失是一个非常复杂的过程,不仅受药剂溶解度的影响,还与药剂、助剂和木材之间的相互作用有关[25−26]。不同木材的构造与性质差异较大也会有一定影响,嘧菌酯在木材上表现出不同的流失性,具体原因需要深入研究。

-

本研究通过高效液相色谱分析方法建立了检测嘧菌酯质量分数的方法,2个分析样品的变异系数为0.45%和0.59%,样品的回收率为98.2%~100.4%,具有较高的精密度及准确度,可用于嘧菌酯质量分数的准确分析。马尾松、杉木和107杨3种处理材的嘧菌酯流失率差异不大,且均表现为低质量分数制剂处理材的流失率大于高质量分数制剂处理材;同时,与乙醇溶解制剂相比,嘧菌酯制成的水基化制剂处理木材不会造成流失率升高,因此嘧菌酯制剂可用于户外处理木材及其制品。

Analytical method of azoxystrobin by HPLC and leaching performance of treated wood

-

摘要:

目的 探究嘧菌酯(azoxystrobin)的高效液相色谱(HPLC)分析方法及抗流失性能,旨在确定嘧菌酯处理材的抗流失性能,为其户外使用提供研究基础。 方法 采用紫外检测器及C18反相色谱柱,通过优化检测波长、流动相组成及配比、柱温及流动相流速等色谱条件,确定分析嘧菌酯的色谱条件,采用外标法对嘧菌酯质量浓度进行检测,并进行标准曲线相关系数、精密度、准确度等分析;参照GB/T 29905—2013《木材防腐剂流失率试验方法》开展流失试验,并利用建立的分析方法测定各处理材流失液中嘧菌酯的质量浓度,以确定防腐材的抗流失性能。 结果 优化得到嘧菌酯分析的色谱条件:V(甲醇)∶V(水)=80∶20为流动相,流速为0.8 mL·min−1,检测波长为220 nm。嘧菌酯标准溶液在质量浓度为1~80 mg·L−1内,标准曲线相关系数为0.999 6,线性相关性强;2个分析样品的变异系数为0.45%和0.59%,样品的回收率为98.2%~100.4%。抗流失试验结果表明:处理材中嘧菌酯的抗流失性较好,马尾松Pinus massoniana、杉木Cunninghamia lanceolata和107杨Populus×euramericana处理材的流失率分别为8.4%~18.8%、8.2%~21.0%和8.8%~19.0%。3种处理材之间的嘧菌酯流失率差异不大,均表现为低质量分数制剂处理材的流失率大于高质量分数制剂处理材的规律;乙醇溶解嘧菌酯处理材的流失率稍高于2种水基化制剂处理材的流失率。 结论 采用HPLC测定嘧菌酯的质量浓度,标准曲线线性相关性强,精密度和准确度高,能准确分析嘧菌酯的质量浓度;嘧菌酯的2种水基化制剂的抗流失性能较好,可用于户外木材及其制品。图6表2参26 -

关键词:

- 木材保护 /

- 嘧菌酯 /

- 高效液相色谱(HPLC) /

- 防腐材 /

- 抗流失性

Abstract:Objective This study, with an exploration of the high performance liquid chromatography (HPLC) analysis method and leaching resistance of the azoxystrobin formulation, is aimed to provide a research basis for its outdoor utilization. Method On the one hand, UV detector and C18 reversed-phase chromatographic column were used for detection before an investigation was conducted of the chromatographic conditions, such as detection wavelength, flow phase composition and ratio, column temperature and flow phase flow rate with further discussion so as to optimize the chromatographic conditions suitable for the analysis of azoxystrobin. On the other hand, the mass concentration of azoxystrobin was detected by external standard method, and the standard curve correlation coefficients, precision and accuracy were evaluated after which the leaching procedure was adopted according to the Chinese standard GB/T 29905−2013 Laboratory Method of Determining the Leachability of Wood Preservatives, and leaching rate of azoxystrobin in treated wood were tested by the established analytical method. Result The optimized chromatographic conditions for analysis of azoxystrobin were as follows: flow phase methanol-water ratio of 80∶20, flow rate of 0.8 mL·min−1, and UV detection wavelength of 220 nm. There was a good linear relationship between azoxystrobin concentration and chromatographic peak area in the range of 1−80 mg·L−1 for azoxystrobin standard solution, with a determination coefficient of 0.999 6. The coefficient variation of samples were 0.45% and 0.59%, and the recovery rates of the samples were 98.2%−100.4%. The leaching rate of azoxystrobin from Pinus massoniana, Cunninghamia lanceolata and Populus×euramericana were 8.4%−18.8%, 8.2%−21.0% and 8.8%−19.0%, respectively, with little difference in leaching rates between the three treated woods. The leaching rate of azoxystrobin in the treated Pinus massoniana, C. lanceolata and Populus×euramericana were all below 21% and the leaching resistance were excellent. All of the three tree species exhibit a pattern where the leaching rate of low concentration treated woods is greater than that of high concentration treated woods whereas the leaching rate of the treated wood with ethanol-dissolved azoxystrobin was slightly higher than that of the water-based formulations. Conclusion The HPLC method for determining azoxystrobin mass concentration showed good linear correlation of the standard curve, high precision, and recovery rate, which can be used for analysis of azoxystrobin mass concentration. The leaching resistance of the two water-based formulations of azoxystrobin was good and can be used for outdoor treatment of wood and its products. [Ch, 6 fig. 2 tab. 26 ref.] -

表 1 精密度试验结果

Table 1. Precision test results

试样 平行试样质量分数/% 标准偏差/% 变异系数/% 1 2 3 4 5 6 平均值 制剂A1 10.06 10.17 10.13 10.23 10.20 10.12 10.15 0.06 0.59 制剂A2 10.17 10.18 10.11 10.09 10.07 10.15 10.13 0.05 0.45 表 2 准确度试验结果

Table 2. Accuracy recovery test results

试样

编号本底值/

(mg·L−1)加入标样量/

(mg·L−1)理论值/

(mg·L−1)实测值/

(mg·L−1)回收率/

%1 0 10 10.00 9.82 98.2 2 0 20 20.00 19.94 99.7 3 0 40 40.00 39.66 99.1 4 28.16 10 38.16 38.24 100.2 5 28.16 20 48.16 48.28 100.3 6 28.16 40 68.16 68.42 100.4 -

[1] 孙芳利, PROSPER N K, 吴华平, 等. 木竹材防腐技术研究概述[J]. 林业工程学报, 2017, 2(5): 1−8. SUN Fangli, PROSPER N K, WU Huaping, et al. A review on the development of wood and bamboo preservation [J]. Journal of Forestry Engineering, 2017, 2(5): 1−8. [2] 劳万里, 段新芳, 吕斌, 等. 碳达峰碳中和目标下木材工业的发展路径分析[J]. 木材科学与技术, 2022, 36(1): 87−91. LAO Wanli, DUAN Xinfang, LÜ Bin, et al. Development path of China wood industry under the targets of carbon dioxide emission peaking and carbon neutrality [J]. Chinese Journal of Wood Science and Technology, 2022, 36(1): 87−91. [3] 张斌, 马星霞, 张景朋, 等. 含石蜡水基型有机木材保护复合制剂的性能研究[J]. 浙江农林大学学报, 2022, 39(2): 423−429. ZHANG Bin, MA Xingxia, ZHANG Jingpeng, et al. Preparation and properties of containing paraffin water based organic wood protective agent [J]. Journal of Zhejiang A&F University, 2022, 39(2): 423−429. [4] 张景朋, 蒋明亮, 马星霞, 等. 甲氧基丙烯酸酯类制剂的木材防腐性能研究[J]. 北京林业大学学报, 2021, 43(3): 131−137. ZHANG Jingpeng, JIANG Mingling, MA Xingxia, et al. Wood decay performance of strobilurins preservatives [J]. Journal of Beijing Forestry University, 2021, 43(3): 131−137. [5] 孙芳利, 鲍滨福, 陈安良, 等. 有机杀菌剂在木竹材保护中的应用及发展展望[J]. 浙江农林大学学报, 2012, 29(2): 272−278. SUN Fangli, BAO Binfu, CHEN Anliang, et al. Application and prospect of organic biocides in timber preservation [J]. Journal of Zhejiang A&F University, 2012, 29(2): 272−278. [6] SHAO Chuang, MA Xingxia, JIANG Mingliang, et al. In-situ growth of hexaconazole/polydopamine/hexadecyltrimethoxysilane in multi-scale structured wood to prepare superhydrophobic wooden materials with decay resistance [J/OL]. Chemical Engineering Journal, 2023, 476 : 146396[2024-05-01]. DOI: 10.1016/j.cej.2023.146396. [7] BARTLETT D W, CLOUGH J M, GODWIN J R, et al. The strobilurin fungicides [J]. Pest Management Science, 2002, 58(7): 649−662. [8] 赵培亮. 新型Strobilurins衍生物的设计、合成及生物活性研究 [D]. 武汉: 华中师范大学, 2008. ZHAO Peiliang. Design Synthesis and Bioactivity of Novel Strobilurin Derivatives [D]. Wuhan: Huazhong Normal University, 2008. [9] 张景朋, 蒋明亮, 马星霞, 等. 一种微乳液型木竹材防腐剂及其制备方法: CN112476682B[P]. 2020-12-03. ZHANG Jingpeng, JIANG Mingling, MA Xingxia, et al. One kind of micro emulsion wood & bamboo preservative and its preparation method: CN112476682B [P]. 2020-12-03. [10] ZHANG Jingpeng, JIANG Mingliang, ZHANG Bin, et al. Mold and stain resistance of bamboo treated with pyraclostrobin fungicide [J/OL]. Polymers, 2022, 14 (24): 5537[2024-05-01]. DOI: 10.3390/polym14245537. [11] YU Lili, CAO Jinzhen, COOPER P A, et al. Effect of hot air post-treatments on copper leaching resistance in ACQ-D treated Chinese fir [J]. European Journal of Wood & Wood Products, 2009, 67: 457−463. [12] WANG Qingping, CAO Jinzhen, JIANG Mingling. Self-healing coating to reduce isothiazolinone (MCI/MI) leaching from preservative-treated bamboo [J]. BioResources, 2020, 15(1): 1904−1914. [13] JANIN A, COUDERT L, MERCIER G, et al. Copper extraction and recovery from alkaline copper quaternary and copper azole treated wood using sulfuric acid leaching and ion exchange or electrodeposition [J/OL]. Journal of Cleaner Production, 2021, 279 : 123687[2024-05-01]. DOI: 10.1016/j.jclepro.2020.123687. [14] 韩利平, 王卿平, 张景朋, 等. IPBC高效液相色谱分析方法及处理材抗流失性能[J]. 北京林业大学学报, 2021, 43 (5): 140−146. HAN Liping, WANG Qingping, ZHANG Jingpeng, et al. Analytical method of IPBC by HPLC and leachability in treated wood and bamboo [J]. Journal of Beijing Forestry University, 2021, 43 (5): 140−146. [15] 陈秀宽, 顾静, 梁少东, 等. 气相色谱-串联质谱法测定茶叶中嘧菌酯残留量的不确定度评定[J]. 食品安全导刊, 2022(5): 61−64. CHEN Xiukuan, GU Jing, LIANG Shaodong, et al. Uncertainty evaluation for the determination of azoxystrobin residues in tea by gas chromatography-tandem mass spectrometry [J]. China Food Safety, 2022(5): 61−64. [16] 孙钰洁, 颜明. 28%三环唑·嘧菌酯悬浮剂的高效液相色谱分析[J]. 世界农药, 2022, 44(3): 57−60. SUN Yujie, YAN Ming. An analysis method of tricyclazole·azoxystrobin 28% SC by HPLC [J]. World Pesticide, 2022, 44(3): 57−60. [17] 王陈杰, 余德勉, 王丹斌, 等. 40%粉唑醇·嘧菌酯悬浮剂分析方法研究[J]. 农药科学与管理, 2020, 41(12): 39−42. WANG Chenjie, YU Demian, WANG Danbin, et al. Development of 40% azoxystrobin·flutriafol SC analytical method [J]. Pesticide Science and Administration, 2020, 41(12): 39−42. [18] 中国木材标准化技术委员会. 木材防腐剂流失率试验方法: GB/T 29905—2013[S]. 北京: 中国标准出版社, 2013. National Technical Committee on Timber of Standardization Administrator of China. Laboratory Method of Determining the Leachability of Wood Preservatives: GB/T 29905−2013 [S]. Beijing: Standards Press of China, 2013. [19] 张景朋, 张卿硕, 吴玉章, 等. 防腐木材中戊唑醇和丙环唑的高效液相色谱分析方法[J]. 林业工程学报, 2022, 7(5): 99−105. ZHANG, Jingpeng, ZHANG Qingshuo, WU Yuzhang, et al. Determination of the content of tebuconazole and propiconazole in treated wood by high performance liquid chromatography [J]. Journal of Forestry Engineering, 2022, 7(5): 99−105. [20] 孔璐璐, 范丽岩, 王晓岗. 高效液相色谱技术中常见问题分析及解决方法[J]. 实验室科学, 2021, 24(2): 95−98. KONG Lulu, FAN Liyan, WANG Xiaogang. Analysis and solutions of common problems in high performance liquid chromatography [J]. Laboratory Science, 2021, 24(2): 95−98. [21] 李晓文, 席丽霞, 蒋明亮. 5种三唑微乳液及其铜胺制剂的抗流失性能[J]. 林业科学, 2017, 53(3): 147−153. LI Xiaowen, XI Lixia, JIANG Mingling. The leachability of five kinds of triazoles and their copper triazole formulations [J]. Scientia Silvae Sinicae, 2017, 53(3): 147−153. [22] 冷阳. 对氯虫苯甲酰胺和嘧菌酯等的制剂及开发思路的分析和评价[J]. 世界农药, 2012, 34(1): 49−55. LENG Yang. Analysis and evaluation of formulations of chlorantraniliprole and azoxystrobin as well as their development ideas [J]. World Pesticide, 2012, 34(1): 49−55. [23] 张景朋, 张卿硕, 蒋明亮, 等. 醚菌酯高效液相色谱分析方法及其防腐材抗流失性能研究[J]. 木材科学与技术, 2023, 37(2): 66−71. ZHANG Jingpeng, ZHANG Qingshuo, JIANG Mingling, et al. Analytical method of kresoxim-methyl by HPLC and leaching performance from treated wood [J]. Chinese Journal of Wood Science and Technology, 2023, 37(2): 66−71. [24] 席丽霞. 三唑类木材防腐剂的制备及其性能研究 [D]. 北京: 中国林业科学研究院, 2014. XI Lixia. Study on Preparation and Properties of Triazole Wood Preservatives [D]. Beijing: Chinese Academy of Forestry, 2014. [25] ZHANG J, KAMDEM D P. FTIR characterization of copper ethanolamine-wood interaction for wood preservation [J]. Holzforschung, 2000, 54(2): 119−122. [26] KARTAL S N, BRISCHKE C, RAPP A O, et al. Biological effectiveness of didecyl dimethyl ammonium tetrafluoroborate (DBF) against basidiomycetes following preconditioning in soil bed tests [J]. Wood Science and Technology, 2006, 40(1): 63−71. -

-

链接本文:

https://zlxb.zafu.edu.cn/article/doi/10.11833/j.issn.2095-0756.20240339

下载:

下载: