-

热固性树脂浸渍纸高压装饰层积板(high-pressure decorative laminates made from thermosetting resins impregnated sheets, HPL)是由不同树脂浸渍的表层纸、装饰纸和多层牛皮纸层积后在高压下热压而成的一种装饰材料[1]。HPL的层压复合结构赋予其优异的耐热、耐磨、耐化学等表面性能,当前HPL广泛应用于实验室、医院和商业场所等[2]。但是由于三聚氰胺甲醛(MF)树脂具有硬而脆、稳定性差的特点[3],使得HPL的韧性较差。在 HPL芯层加入纳米纤维或使用化学药剂改性浸渍树脂可有效改善HPL的脆性问题,同时赋予HPL机械强度、水解稳定性、耐火性等功能[4−5]。JI等[6]以牛皮纸作为HPL的底层材料,在2层牛皮纸中间加入无纺布醋酸纤维素(CA)纳米纤维垫,提升HPL的弯曲性能。当加入5层CA纳米纤维垫时,HPL的断裂伸长率为 27.9%,屈服强度为40.8 MPa,分别比原始HPL提高了4.4和5.9倍。但是使用静电纺丝法制备 CA 纳米纤维存在耗时长和成本高等问题。

HPL的外观和质感主要由表层装饰纸决定,近年来,数码打印和同步对纹技术可以使 HPL呈现不同的纹理、图案和颜色[7],但仍缺乏木质材料特有的自然纹理和亲和触感。重组装饰薄木是利用普通速生材生产的一种饰面材料,不仅具有天然木材的纹理和质感,而且原材料来源广泛[8]。以重组装饰薄木为基本单元,借鉴 HPL的层压复合结构,有望制备出一种性能优异的木质复合装饰板材,在轨道交通、室内装修、公共场所等领域具有广阔的应用前景。

胶黏剂和胶接技术在木质材料复合中发挥着重要作用,除了保证胶合质量外,环保性能、胶接效率和生产能耗均是工业界和学术界关注的重点。近年来,聚乙烯(PE)薄膜以其环境友好性、良好的柔韧性、耐水性和加工性等优势,成为传统的“三醛胶”木质复合材料的有效替代产品,广泛用于木质材料的胶接[9−10]。 PE薄膜具有受热软化、冷却固化的特性[11],其对木质材料的胶合是在木材表面熔融软化、流展、渗透和冷却固化的过程[12−13]。适宜的工艺条件下,熔融的热塑性树脂大分子在木材多孔性结构中的填充及其对损坏细胞的修复作用[14],能够赋予热塑性树脂复合材料优良的力学强度和耐水性能[15−16]。为了制备一种无醛、性能优异的装饰板,本研究提出使用PE薄膜对重组装饰薄木进行胶合以制备薄木-PE复合层积装饰板(wooden decorative laminates-sheets made from polyethylene film, WDL)。通过响应面方法分析热压温度、热压时间、热压压力对装饰板浸渍剥离性能和顺纹抗拉强度的影响,模拟优化出WDL的最佳制备条件,为推进其应用提供参考依据。

-

重组装饰薄木:椴木科技木,购于德清洛舍佳朋木皮厂,规格为200 mm×200 mm,厚度为0.2 mm,含水率为6%~12%;PE薄膜:购于沭阳登农商贸有限公司,厚度为0.1 mm,密度为0.91 g·cm−3。

-

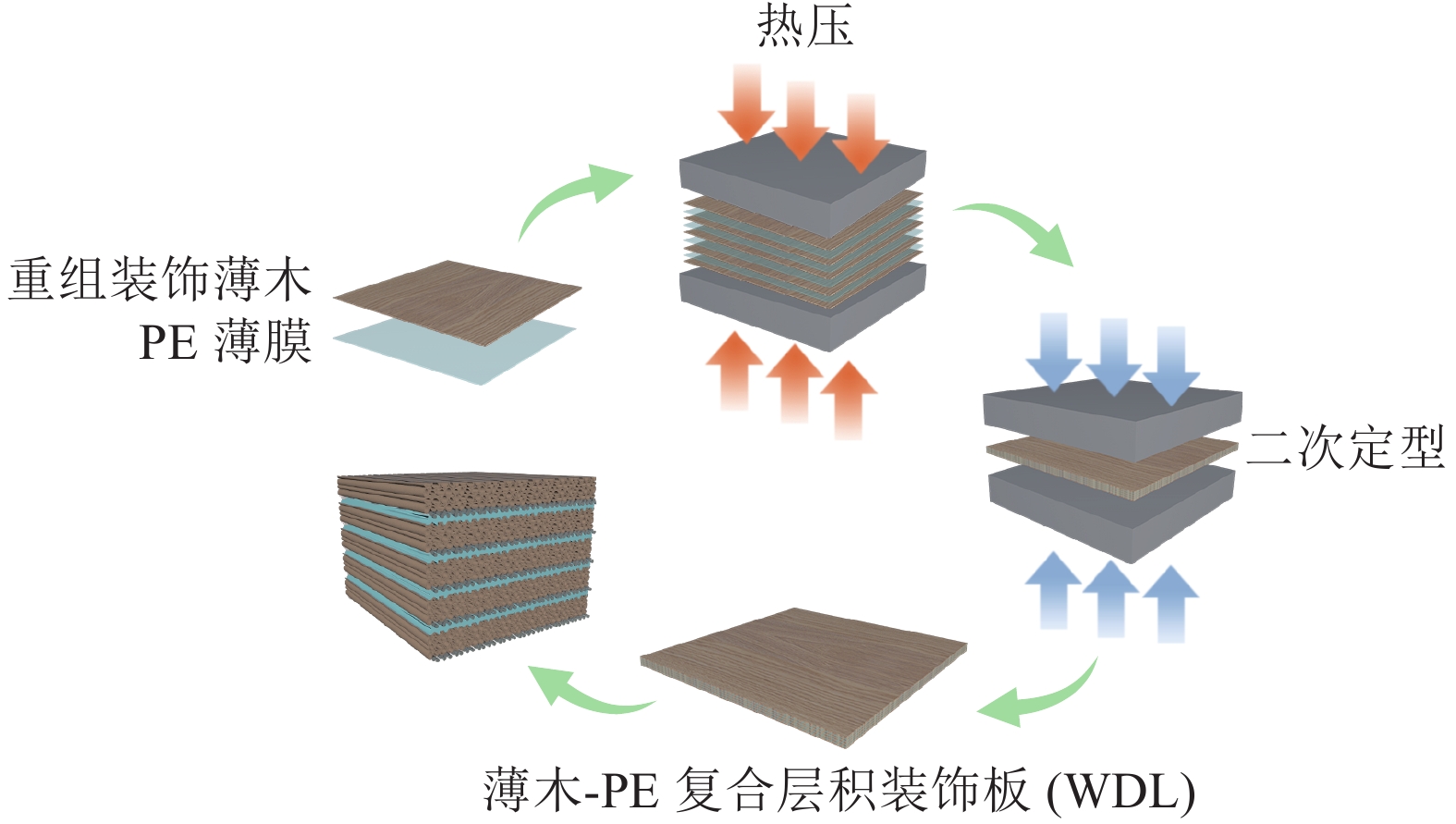

采取顺纹的方式将重组装饰薄木和 PE 薄膜进行组坯并热压复合,制备5层结构的薄木-PE复合层积装饰板(图1)。

-

以热压温度、热压时间、热压压力3个因素为自变量,以浸渍剥离长度(Y1)和顺纹抗拉强度(Y2)为响应值,选用3因素3水平进行响应面试验设计(表1)。应用Design Expert 13,建立数学回归模型,优化WDL的热压工艺。为了避免冷却过程中PE薄膜收缩产生的内应力,热压结束后对WDL进行二次冷压定型处理,定型时间为4 min,定型压力为1 MPa。

水平 因素 热压温度(A)/℃ 热压时间(B)/s 热压压力(C)/MPa $ - $1 130 30 0.50 0 155 90 1.25 $ + $1 180 150 2.00 Table 1. Level of experimental factors

-

根据响应面试验结果,得出最优的热压工艺参数,对最优工艺条件下的WDL进行浸渍剥离性能和顺纹抗拉强度的测试,选取测试的数据与响应面模型计算的预测值对比,以验证其可靠性。本研究利用Design Expert 13 进行数据分析和模型模拟,利用Origin 2021绘图。

-

浸渍剥离性能:根据国家标准GB/T 17657—2022《人造板及饰面人造板理化性能试验方法》中浸渍剥离性能测试要求,取尺寸为75 mm×75 mm的试件,将其放在(63±3) ℃热水中浸渍3 h,然后放置于(63±3) ℃的恒温干燥箱中干燥3 h。观察并测量试件每个胶层各边剥离的长度,结果精确至1 mm。测试结果为6个试件的平均值。

顺纹抗拉强度:根据国家标准GB/T 1040.2—2022《塑料 拉伸性能的测定 第2部分:模塑和挤塑塑料的试验条件》进行制样,在万能力学试验机上对薄木和 WDL 试样进行载荷-位移和强度的测试,试验速度为1 mm·min−1。测试结果为6个试件的平均值。

PE薄膜拉伸强度:根据国家标准GB/T 1040.3—2006《塑料 拉伸性能的测定 第3部分:薄膜和薄片的试验条件》中5型试样的形状和尺寸进行制样,在万能力学试验机上进行测试,试验速度为5 mm·min−1。测试结果为6个试件的平均值。

胶接界面形貌:将试样制备成尺寸为 7 mm×3 mm×1 mm (L×W×T)的样块,把样块导管侧黏附在铜片上,进行喷金处理后,使用环境扫描电子显微镜(FEI Quanta 200)观察重组装饰薄木和 PE 薄膜的胶接界面形貌。

-

以浸渍剥离长度和顺纹抗拉强度为指标,利用响应面法Box-Behnken模型试验考察热压温度、热压时间和热压压力对 WDL 性能的影响。响应面试验方案及结果见表2。

编号 热压温度

(A)/℃热压时间

(B)/s热压压力

(C)/MPa浸渍剥离长度

(Y1)/mm顺纹抗拉强度

(Y2)/MPa编号 热压温度

(A)/℃热压时间

(B)/s热压压力

(C)/MPa浸渍剥离长度

(Y1)/mm顺纹抗拉强度

(Y2)/MPa1 −1 −1 0 33 34.5 10 0 1 −1 0 43.0 2 1 −1 0 1 36.9 11 0 −1 1 8 43.3 3 −1 1 0 11 41.7 12 0 1 1 8 40.5 4 1 1 0 0 33.6 13 0 0 0 3 40.4 5 −1 0 −1 26 38.4 14 0 0 0 2 44.0 6 1 0 −1 0 37.7 15 0 0 0 6 44.2 7 −1 0 1 25 40.8 16 0 0 0 3 42.0 8 1 0 1 0 33.2 17 0 0 0 1 39.5 9 0 −1 −1 25 40.7 Table 2. Design and results of response surface test

以表2的结果进行响应面回归模型的方差分析,结果见表3。浸渍剥离长度的拟合模型极显著(P<0.000 1),决定系数(R2)=98.45%,校正决定系数($R_{\mathrm{Adj}}^2 $)=96.45%,与R2接近,说明响应面分析方法对浸渍剥离性能的评估是有效的。顺纹抗拉强度的拟合模型显著(P<0.05),且失拟项不显著(P>0.05)。分析结果中R2=88.98%>85%,说明该模型对WDL的顺纹抗拉强度预测结果可信。因此本研究设计方法及模型可较好地反映热压温度、热压时间、热压压力与WDL浸渍剥离长度之间的关系。

方差

来源浸渍剥离长度(Y1)/mm 顺纹抗拉强度(Y2)/MPa 平方和 均方 F P 平方和 均方 F P 模型 1 934.44 214.94 49.33 <0.000 1** 173.76 19.31 6.28 0.012 1* A 1 104.50 1 104.50 253.49 <0.000 1** 24.50 24.50 7.97 0.025 7* B 288.00 288.00 66.10 <0.000 1** 1.45 1.45 0.47 0.515 0 C 12.50 12.50 2.87 0.134 1 0.50 0.50 0.16 0.698 8 AB 110.25 110.25 25.30 0.001 5** 27.56 27.56 8.97 0.020 1* AC 0.25 0.25 0.06 0.817 6 11.90 11.90 3.87 0.089 8 BC 156.25 156.25 35.86 0.000 5** 6.50 6.50 2.12 0.189 2 A2 121.64 121.64 27.92 0.001 1** 98.94 98.94 32.19 0.000 8** B2 34.80 34.80 7.99 0.025 5* 1.04 1.04 0.40 0.5787 C2 80.59 80.59 18.50 0.003 6** 0.52 0.52 0.17 0.692 3 残差 30.50 4.36 21.52 3.07 失拟项 16.50 5.50 1.57 0.328 1 3.87 1.29 0.29 0.829 9 纯差 14.00 3.50 17.65 4.41 总离差 1 964.94 195.28 R2 0.984 5 0.889 8 RAdj 2 0.964 5 0.748 1 说明:**. 极显著(P<0.01);*. 显著(P<0.05)。$ R^2 $. 决定系数;$ R_{ {\mathrm{Adj} }}^2 $. 校正决定系数。 Table 3. Variance analysis of impregnation peel performance and endwise tensile strength

-

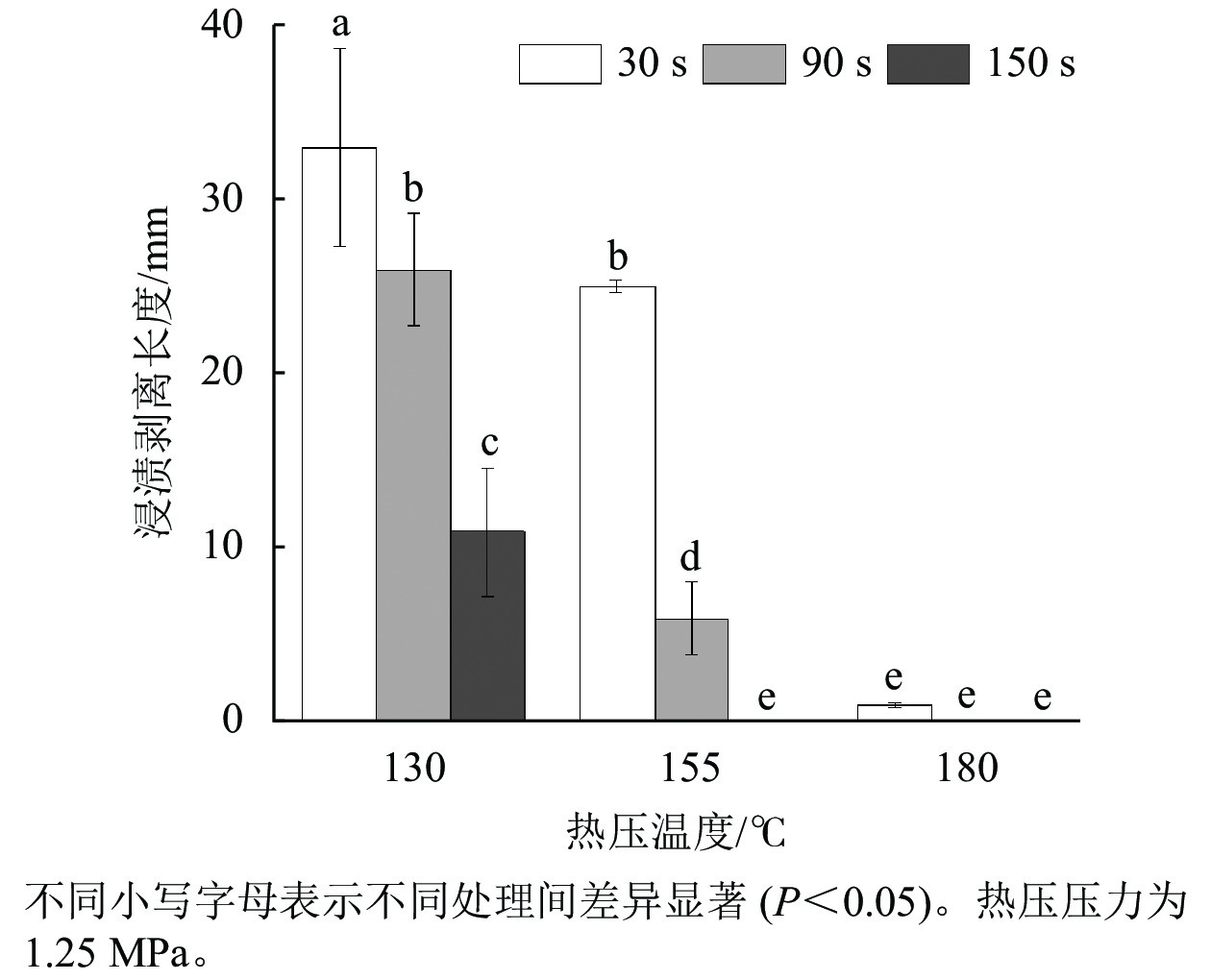

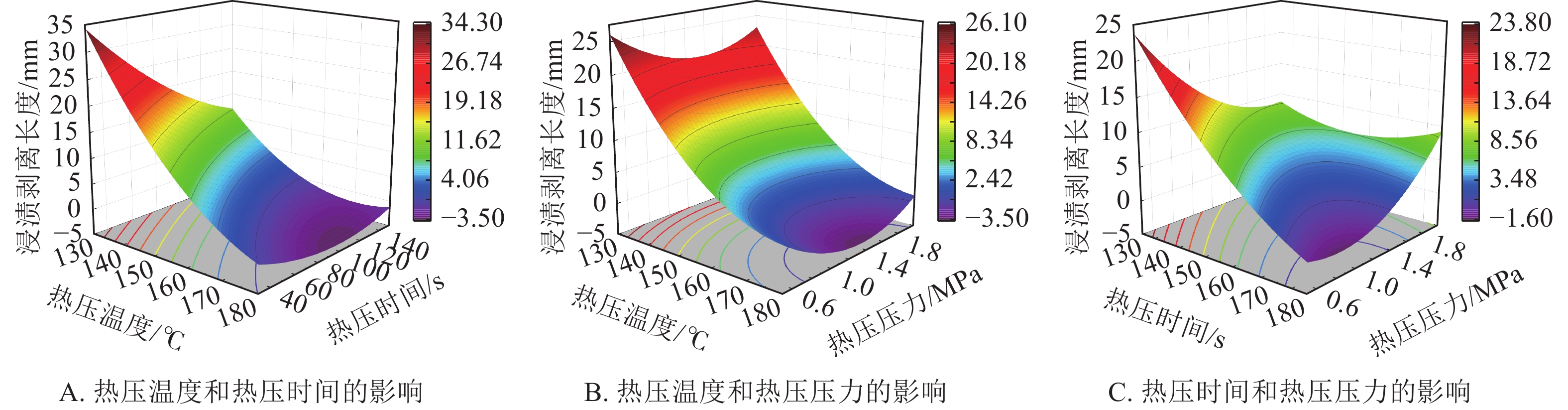

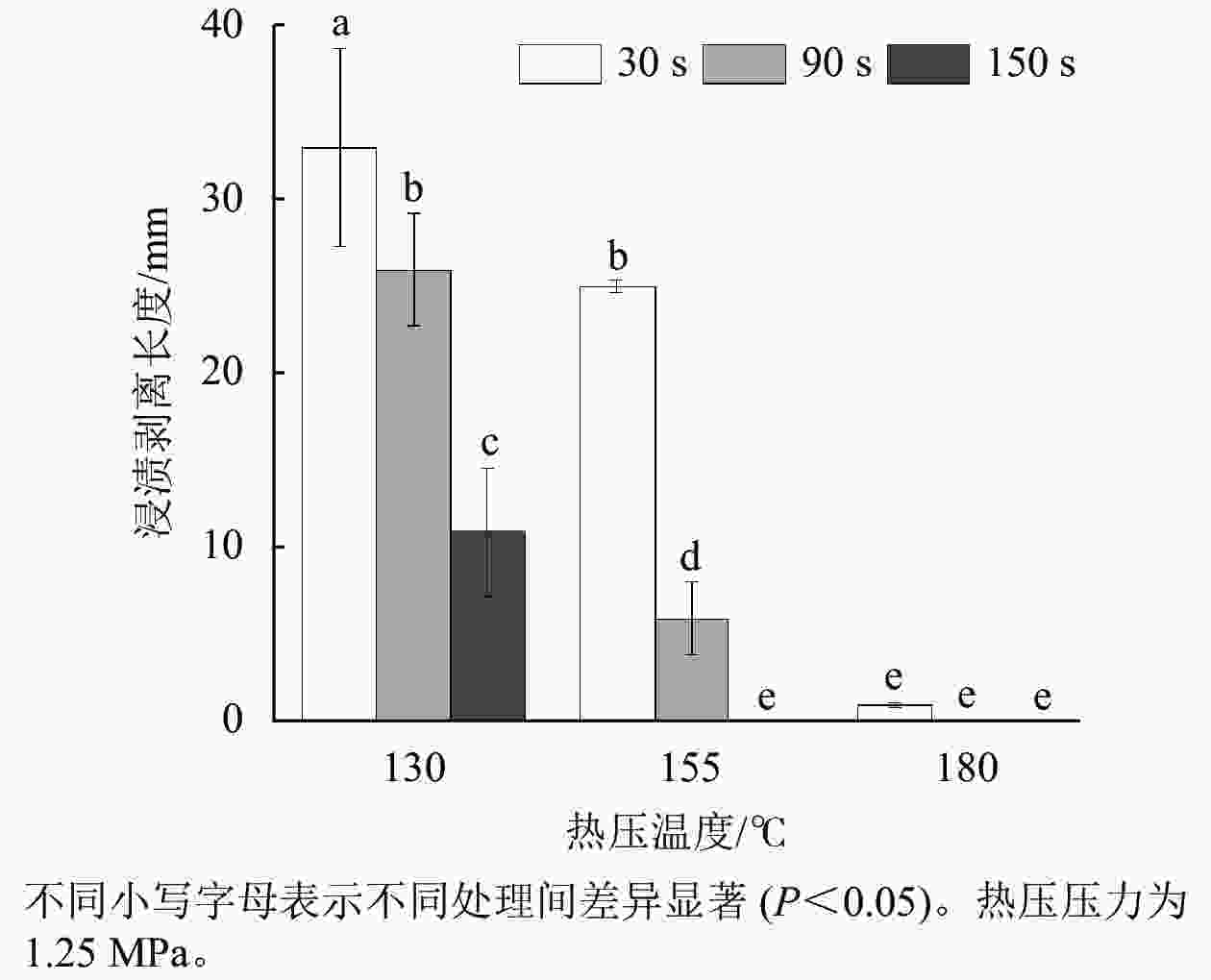

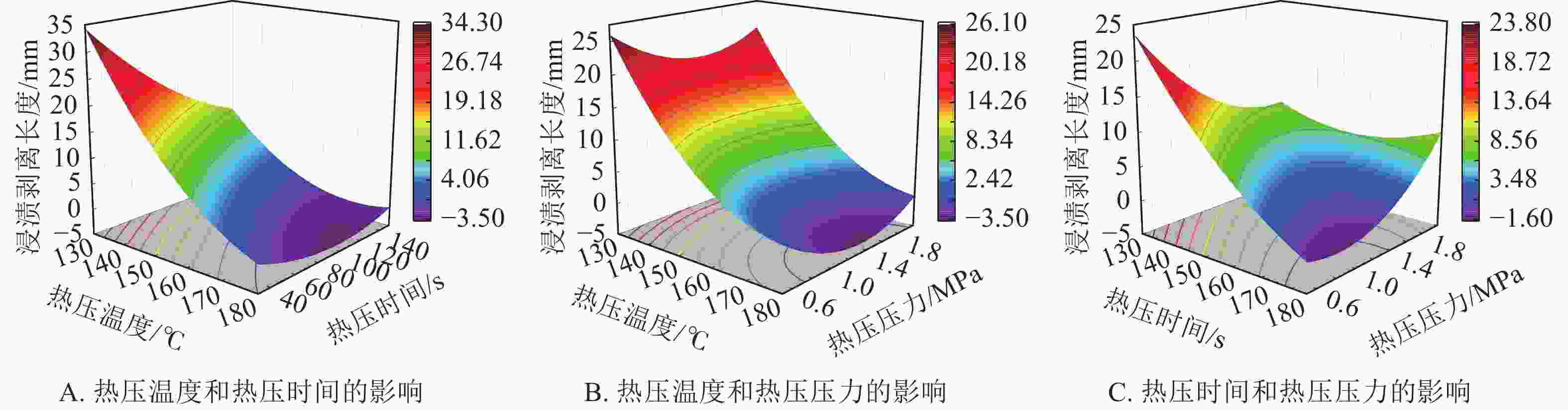

根据表3可知:热压温度和热压时间对WDL的浸渍剥离性能影响极显著(PA<0.000 1,PB<0.000 1)。不同热压温度和热压时间下WDL的浸渍剥离长度见图2,当热压时间固定,升高热压温度可显著降低试件的浸渍剥离长度,温度升高到180 ℃时,试件在Ⅱ类浸渍剥离试验(63 ℃水煮处理)中几乎观察不到胶层开裂的现象。一方面是由于高温可使熔融 PE均匀渗透到重组装饰薄木中,形成胶钉结构;另一方面是薄木在高温条件下进行了短时的热处理,表面极性基团降低,两者界面相容性增强。当热压温度不变,延长热压时间同样可以达到增强试件浸渍剥离性能的目的。当在130 ℃热压温度条件下,热压时间延长至150 s时WDL试件浸渍剥离长度降低到了11 mm,满足Ⅱ类浸渍剥离性能测试要求(≤25 mm)。这是因为低温条件下PE自身的熔融黏度高,流动性差,需要充足的时间才能在重组装饰薄木表面润湿和渗透。由图3A可以看出:热压温度和热压时间的3D响应曲面呈现为向下凹状,倾斜度较高,说明两者存在交互作用且极显著(PAB=0.001 5),因此在实际生产中可以根据实际条件选择合适的热压温度和时间范围。

热压压力可以促进木材与胶黏剂之间的结合,适当施加压力有助于良好胶合界面的形成。从图3B可以看出:当热压温度一定时,WDL 试件的浸渍剥离长度随热压压力的增加呈先下降后上升的趋势,且两者的响应面等高线图接近圆形,表明两者之间交互作用不显著(PAC>0.05)。这是由于压力的持续增大导致熔融PE分子间的作用力增加使树脂整体黏度增大,从而对WDL的浸渍剥离性能产生不利影响。热压温度在180 ℃时,不同压力条件下试件的浸渍剥离长度均趋近于0 mm,由此可见压力增大PE的黏度与温度降低其熔融黏度是一个相互抵冲的作用。当热压温度较适宜时,热压压力对PE黏度的增大占主导作用;但热压温度足够高时,这种反作用会逐步减弱,此时温度减小PE熔融黏度的作用大于压力的增稠作用。

由图3C可知:热压时间和热压压力交互作用的响应面图呈凹陷状,表明浸渍剥离长度在热压时间为90~120 s,热压压力为0.6~1.2 MPa时趋于0 mm。热压时间和热压压力的增加有利于熔融PE的渗透,从而有效提高WDL的耐水性,因此热压时间和热压压力对WDL浸渍剥离性能呈显著交互作用(PBC<0.01)。

-

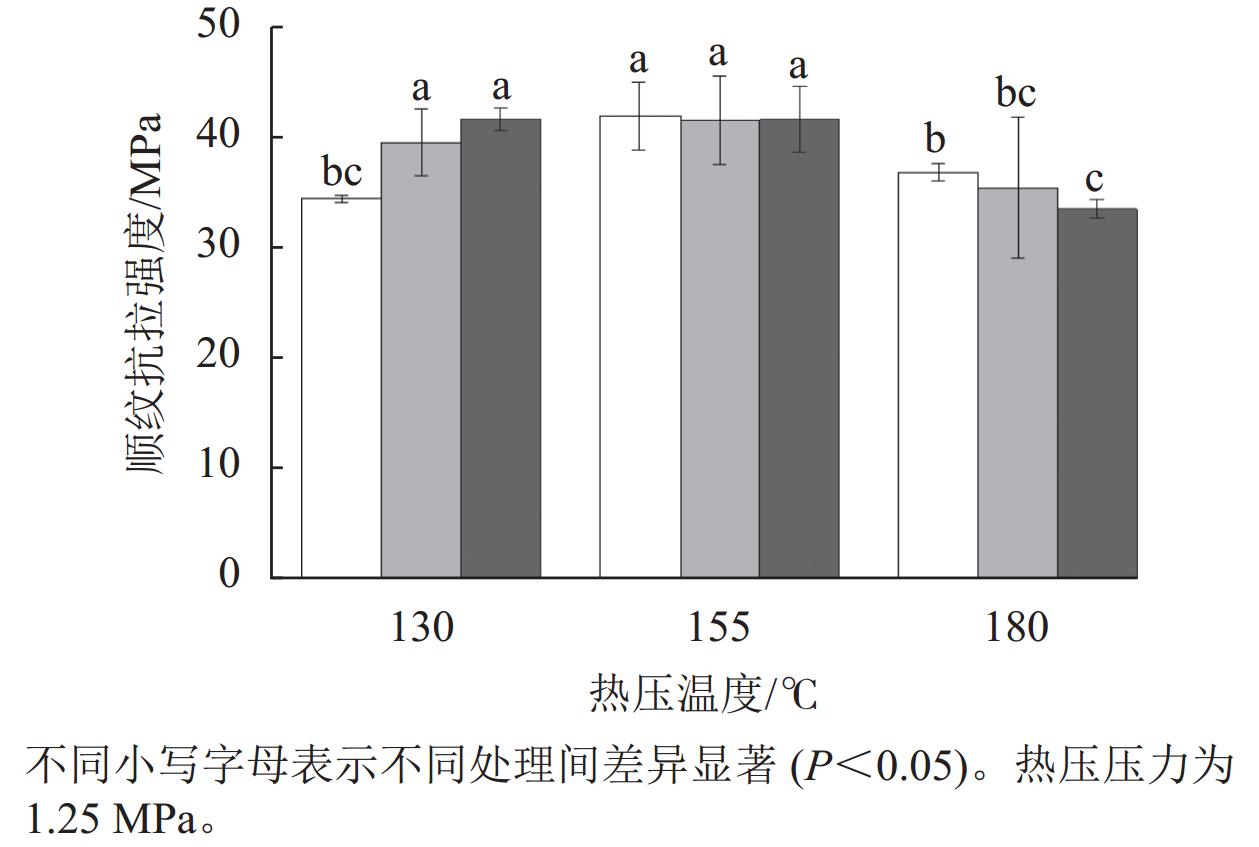

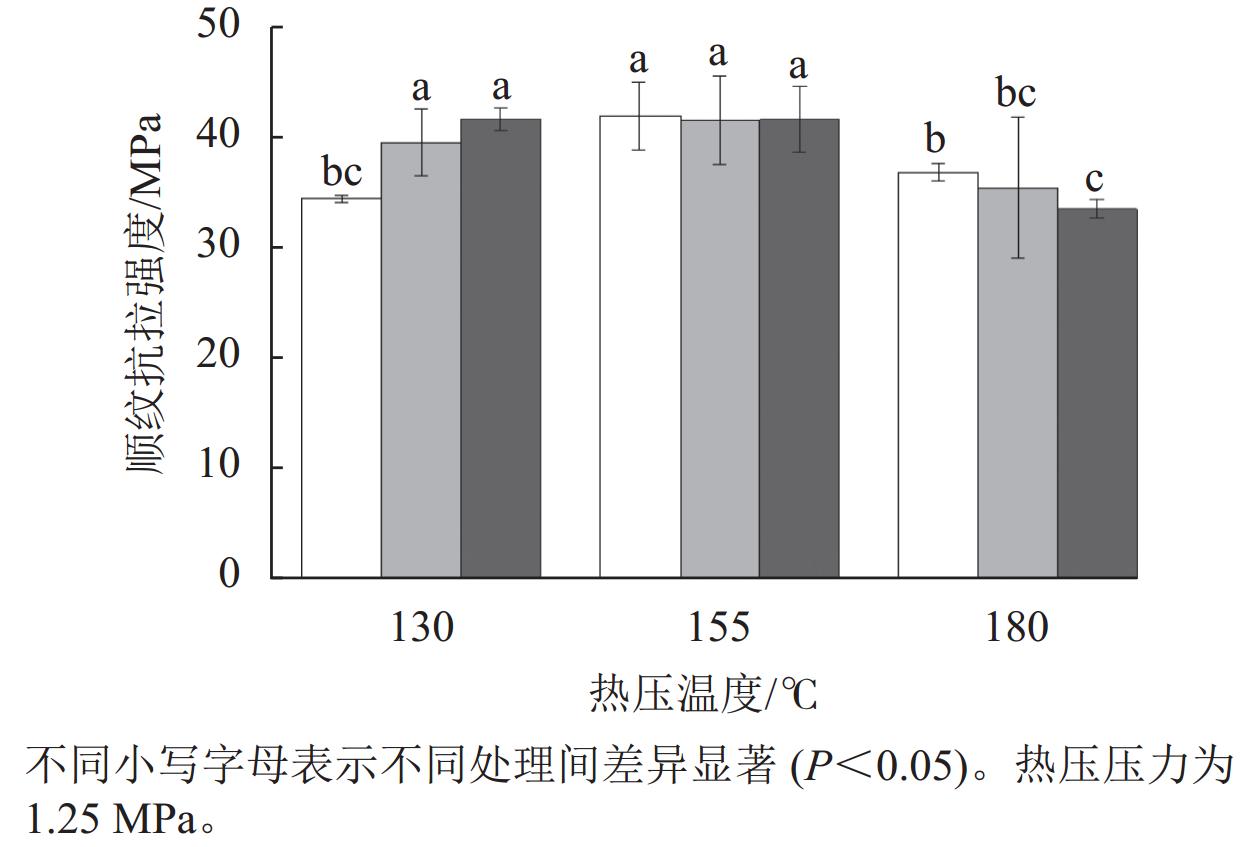

根据顺纹抗拉强度方差分析结果可知,热压温度对 WDL的顺纹抗拉强度有显著影响(PA<0.05),且热压温度和热压时间对其顺纹抗拉强度有显著交互作用(PAB<0.05)。从图4可以看出:相同热压时间条件下,热压温度为155 ℃时WDL的顺纹抗拉强度最大。这是因为130 ℃时制备的WDL未充分结合重组装饰薄木和PE薄膜2种材料的强度优势,导致顺纹抗拉强度较低;而在180 ℃时,由于热压温度的升高和时间的延长,渗入薄木中的熔融PE量增大,导致胶层黏结线变薄。

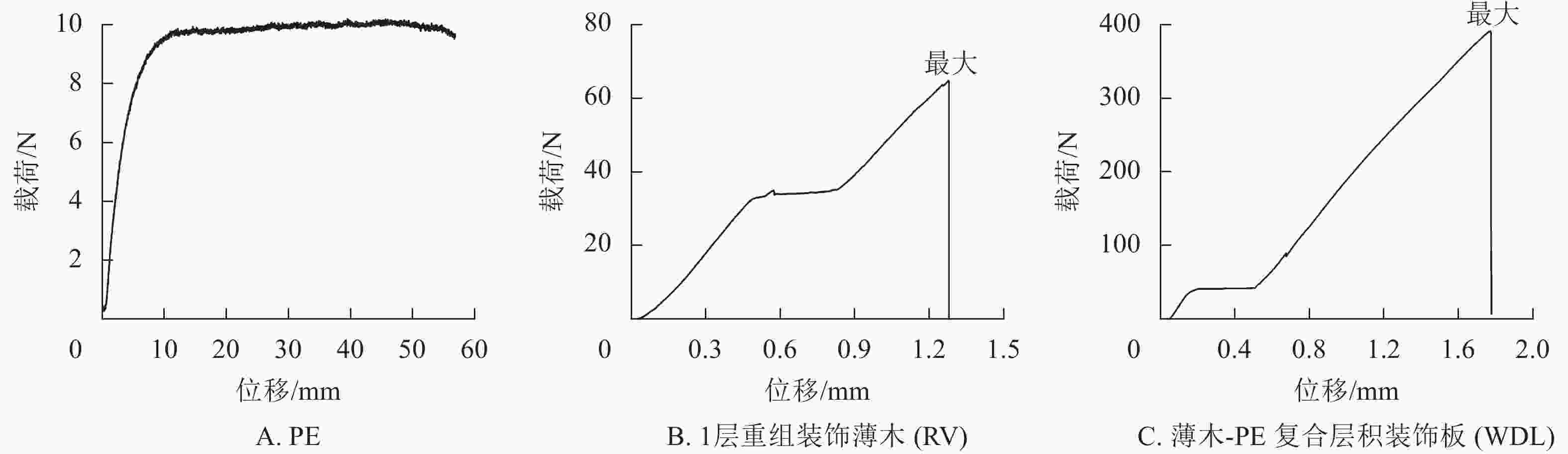

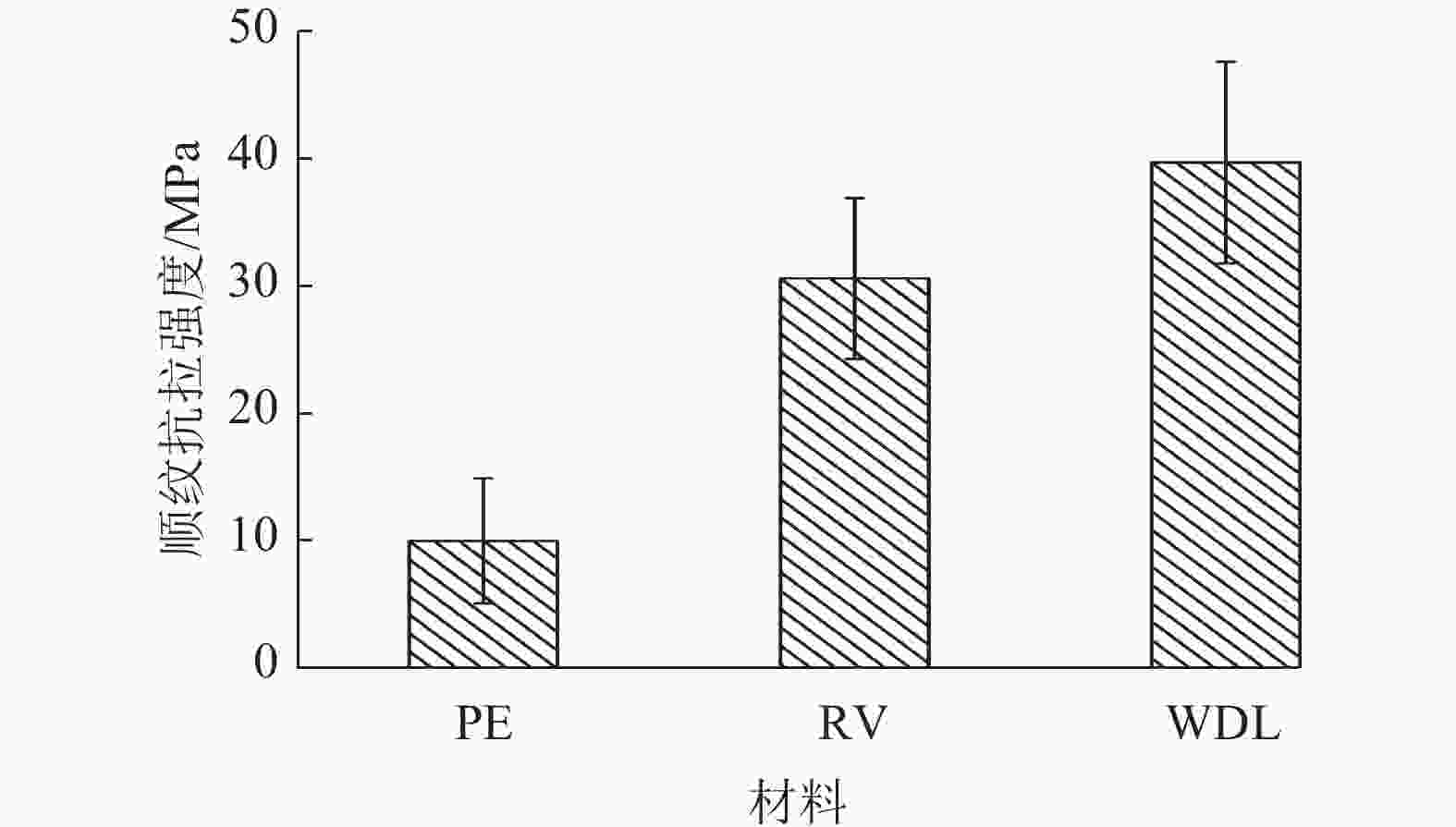

从图5A可以看出:PE受载荷后塑性变形较大,其拉伸强度为10 MPa (图6)。重组装饰薄木的顺纹抗拉载荷-位移曲线如图5B,其断裂伸长率较小,到达最大点时薄木受到最大承载力后发生突然断裂,原始顺纹抗拉强度达30.6 MPa (图6)。WDL的整体断裂趋势与重组装饰薄木相近(图5C),这是因为 PE的添加量较少,对WDL的断裂没有显著影响。层压复合之后的顺纹抗拉强度增加到了39.7 MPa (图6),这说明两者复合以后,重组装饰薄木起着承受载荷的主要作用,而 PE 既是胶黏材料,又可作为增强材料。

根据响应面试验结果可知:WDL的顺纹抗拉强度为33~46 MPa,能满足普通室内装修和家具贴面的要求,为了能够应用到轨道运输内饰领域,后续还需增强其强度。

-

根据 Design Expert 13对方差分析的结果得到 WDL 的浸渍剥离长度(Y1)、顺纹抗拉强度(Y2)为响应值的二次回归方程,分别如式(1)与式(2):

通过软件Design Expert 13对模型回归方程Y1、Y2 进行计算,并综合考虑WDL的性能,得到该模型最佳热压工艺参数为:热压温度160.19 ℃、热压时间109.11 s、热压压力0.96 MPa。该工艺参数条件下 WDL 的浸渍剥离长度理论值为−0.51 mm,顺纹抗拉强度理论值为41.8 MPa。结合实际生产应用,最终确定制备 WDL 最优工艺参数为:热压温度160 ℃、热压时间109 s、热压压力1 MPa。为了进一步验证回归模型的准确性,验证试验得到试件的浸渍剥离长度为0 mm,满足GB/T 17657—2022中Ⅱ类浸渍剥离测试的要求。顺纹抗拉强度实际值为38.2 MPa,达到了预测值的91.39%,实际值与理论预测值拟合度高。本研究数据结果与响应面模型拟合效果好,说明响应面优化的结果可靠。

-

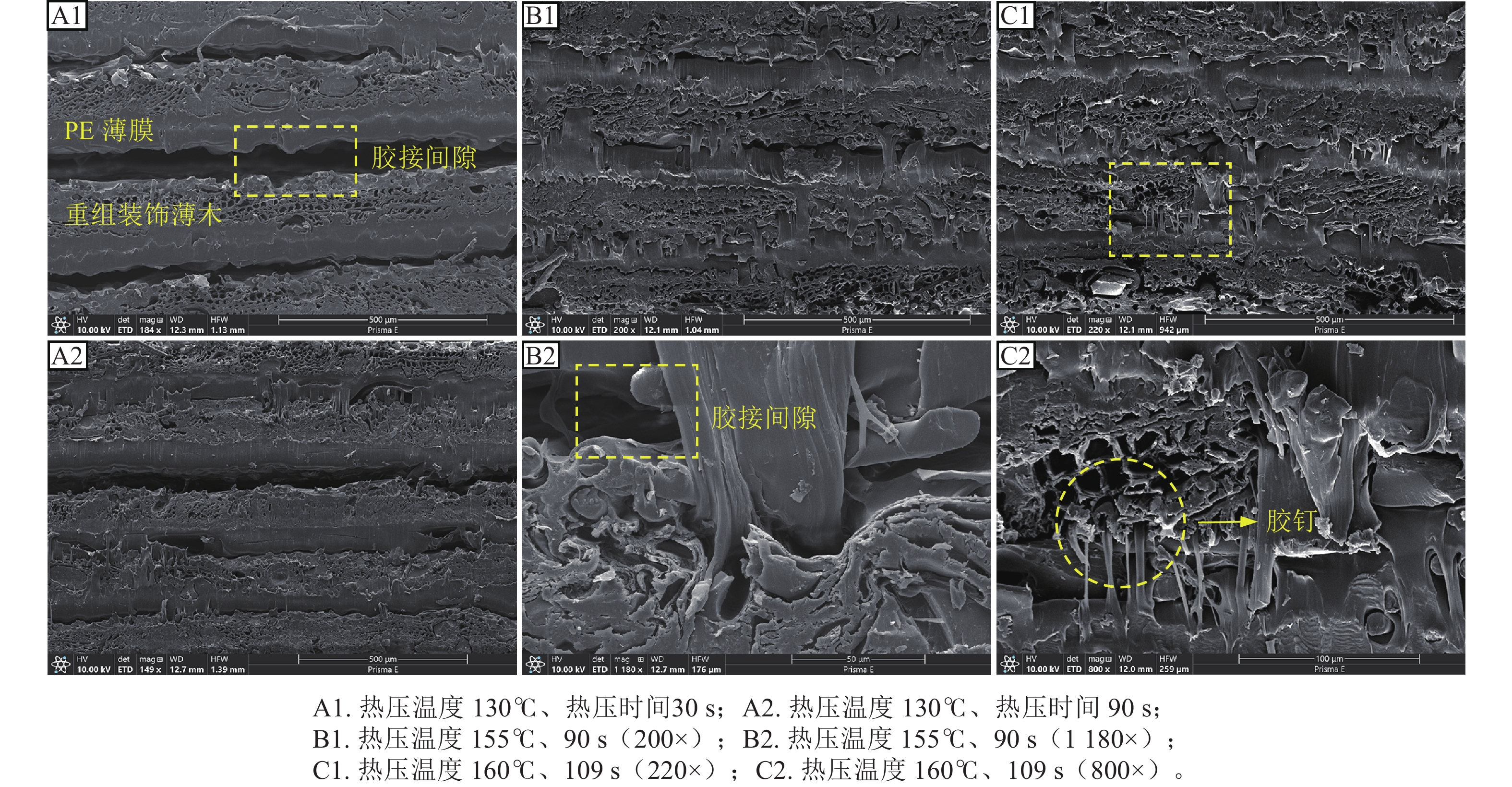

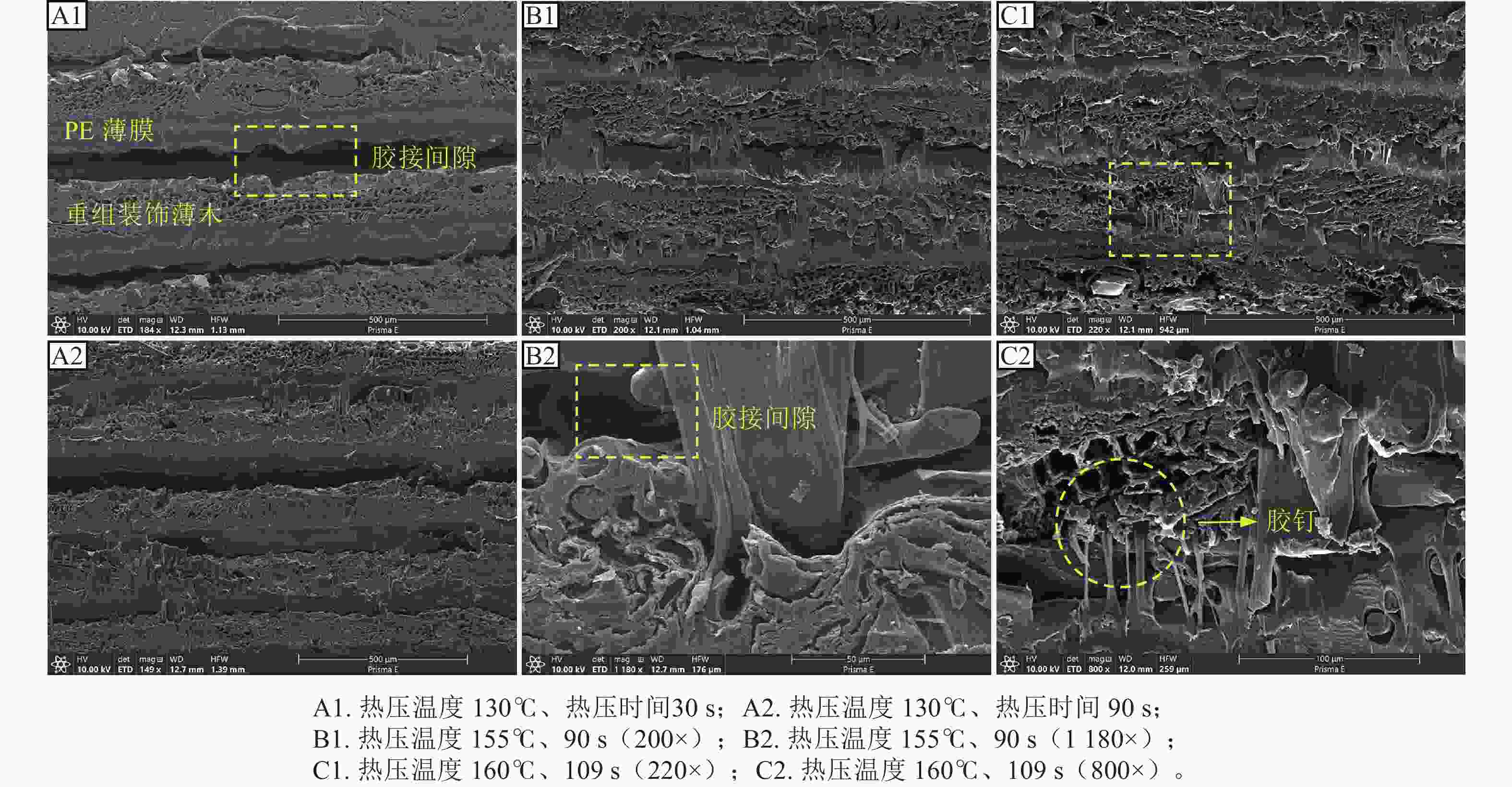

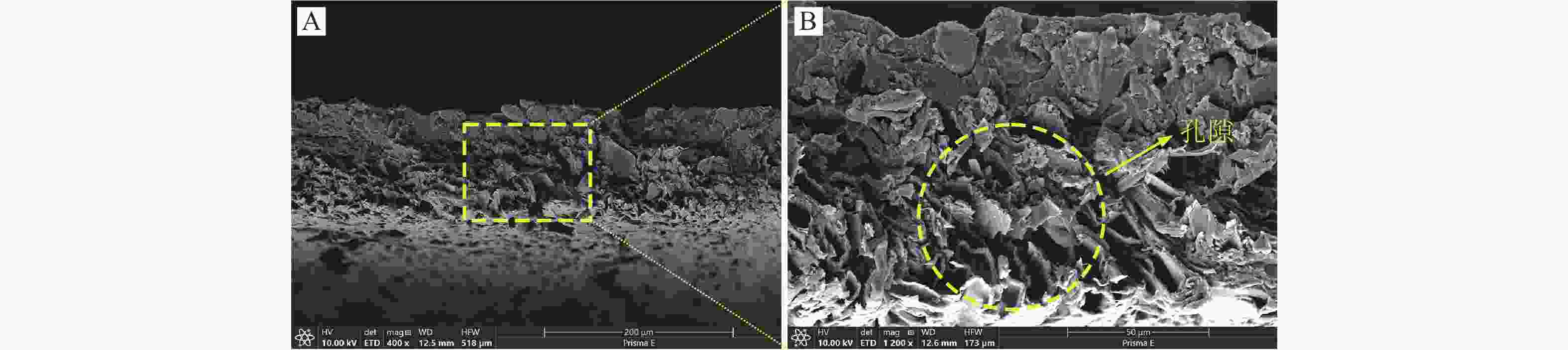

由于木材与 PE胶接时没有化学反应,主要依靠机械互锁进行结合,重组装饰薄木的多孔结构为其胶合提供了有利条件(图7)。PE受热熔融后受到压力和时间的作用渗透到重组装饰薄木的孔隙结构中,形成连续的胶层和机械啮合结构,但WDL是由5层重组装饰薄木组成的,不同热压工艺条件下PE的渗透程度差异明显。如图8A1,在低温短时条件下(130 ℃)热压复合时,几乎每层PE薄膜与重组装饰薄木之间都存在较大的胶接间隙,极大地影响了WDL的力学性能和耐水性能;即使延长热压时间到 90 s(图8A2),仍存在明显的胶合缺陷。而升高温度到155 ℃时(图8B1),两者的胶合质量得到明显改善。上述分析说明热压温度和热压时间对WDL的界面胶接有显著交互作用,且界面胶接的好坏对其整体性能有直接影响,这与前面分析一致。

Figure 8. Microscopic morphologies of WDL’s adhesive interface under different hot-pressing conditions

由最优工艺条件下制备的 WDL 微观形貌图(图8C)可知:该条件下重组装饰薄木和 PE界面结合更加紧密,此时两者已经达到了良好的胶接状态,且有部分熔融PE渗透到薄木导管纹孔中形成更为稳定的胶钉结构,从而提高了WDL的耐水性,其浸渍剥离性能与响应面优化结果相吻合。此时顺纹抗拉强度实际值与预测值接近程度为91.39%,表明模型准确可信。因此该回归模型能够较好地预测和分析热压条件与WDL物理力学性能的关系。

从图8B和8C可以看出:在适宜的温度条件下热压复合时,PE薄膜与重组装饰薄木之间仍存在胶接间隙,这是因为木材与胶黏剂之间由于表面性质不同造成两者复合时难以形成完善的界面胶接层。因此在后续过程中,需对薄木进行改性处理以降低界面胶合缺陷对WDL性能的影响。

-

本研究使用PE薄膜与重组装饰薄木制备无醛复合装饰板,研究热压因子对薄木-PE复合层积装饰板性能的影响,并阐释了热压温度、热压时间和热压压力对PE薄膜与重组装饰薄木的胶合作用机制。

响应面试验结果表明,对WDL浸渍剥离性能影响最大的因素是热压温度和热压时间,而热压压力对其性能影响不显著。这是因为PE薄膜与重组装饰薄木的胶合主要依靠机械啮合结构,热压温度和热压时间的增加降低了PE薄膜的熔融黏度,使其在薄木多孔隙结构中具有更大的渗透性[17]。两者胶接间隙的减小使得水分子难以进入和储存在WDL内部,从而提高其耐水性[18]。WDL的顺纹抗拉强度主要取决于重组装饰薄木本身的强度和厚度,但在热压过程中热压温度也会对WDL的顺纹抗拉强度产生影响。这是因为低温条件下重组装饰薄木和PE薄膜胶接界面的缺陷导致力学性能比较差[19];温度过高则会导致薄木中最热敏的半纤维素发生降解[20−21],从而降低WDL的力学性能。结合响应面试验结果并综合考虑实际生产情况,热压温度为160 ℃、热压时间为109 s、热压压力为1 MPa的工艺条件制备装饰板,实际验证顺纹抗拉强度可达38.2 MPa,与回归方程模型预测值较为接近,其浸渍剥离性能可达Ⅱ类试验要求,耐水性好,且不含甲醛,加之制备工艺简单,具有广阔的发展潜力。

从微观角度看,紧密的机械互锁结构可以增强WDL的耐水性,但是导热不良体的薄木影响芯层的升温速率[22−23],从而不利于熔融PE的渗透,且极性木材与非极性薄膜界面相容性差的问题会导致界面胶接层不完善[24−25]。因此在后续过程中,需对重组装饰薄木进行扎孔或化学改性处理[26],改善两者之间的界面相容性以降低界面胶合缺陷对WDL性能的影响[27]。

-

本研究采用重组装饰薄木和PE薄膜制备的新型无醛薄木-PE复合层积装饰板,后期饰面过程中无需额外涂布胶黏剂,可作为替代 HPL 在室内装修、轨道运输等领域的材料选择。然而所制备的WDL抗拉强度低于轨道运输内饰的要求(≥68.8 MPa),且木质材料遇火易燃,后续需对其强度和阻燃性进行改进和增强。

Preparation and properties optimization of veneer-PE laminated decorative panels

doi: 10.11833/j.issn.2095-0756.20240345

- Received Date: 2024-05-14

- Rev Recd Date: 2024-09-18

- Available Online: 2025-04-01

- Publish Date: 2025-04-01

-

Key words:

- polyethylene film /

- reconstituted decorative veneer /

- Response Surface Methodology /

- impregnation peeling length /

- tensile strength along the grain

Abstract:

| Citation: | LIU Qiongyao, QU Xi, LIU Xiaoqian, et al. Preparation and properties optimization of veneer-PE laminated decorative panels[J]. Journal of Zhejiang A&F University, 2025, 42(2): 393−401 doi: 10.11833/j.issn.2095-0756.20240345 |

DownLoad:

DownLoad: