-

全球每年有1/3~1/2的能源以各种形式消耗在摩擦上,不仅造成了能源浪费与经济损失,甚至会引起生产事故[1−2]。使用合适的润滑剂可以在相互作用的摩擦表面上形成油膜,降低摩擦与磨损,减少能源的浪费,延长机械使用寿命。润滑脂是一种将稠化剂分散到基础油中进行增稠得到的半固态润滑剂产品,具有黏度大、耐压性强、密封性好以及减震降噪等优点,在钢铁、化工、采矿以及冶金等行业得到了广泛的应用[3−5]。现在市面上的润滑脂是以不可再生的石化资源为原料生产的。随着全球石化资源的日益枯竭以及开采和使用过程中带来的环境污染问题,以可再生的生物基材料为原料制备润滑脂近年来成为了研究热点[6−8]。润滑脂主要由基础油(65%~95%)、稠化剂(5%~35%)以及添加剂(0~10%)组成。目前,关于生物基润滑脂的相关研究尚处于起步阶段,主要在基础油的开发,通常的做法是以植物油代替矿物油制备生物基润滑脂。用于制备润滑脂的常见植物油包括蓖麻油[9−11],大豆油[12−14]和菜籽油[15−17]等。RAWAT等[18]以蓖麻油为基础油制备了锂基润滑脂,并用二硫化钼(MoS2)和氧化石墨烯纳米片作为添加剂,发现二维片状纳米材料可以显著改善蓖麻油基润滑脂的摩擦学性能。LIU等[13]以环氧大豆油为基础油,锂皂和三乙醇铵聚皂的混合物为稠化剂制备了润滑脂,发现聚皂结构中的交联可以提供润滑脂更高的抗变形能力,并且摩擦系数显著低于未添加聚皂的润滑脂。但目前关于润滑脂生物基稠化剂的研究还较少,且以金属皂和聚脲稠化剂为主[19−22]。金属皂和聚脲稠化剂的价格不稳定,限制了润滑脂行业的可持续发展。在“碳达峰”和“碳中和”的背景下,纤维素凭借可再生可降解、绿色环保以及储量丰富等优点受到了人们的青睐[23−25]。本研究以天然纤维素和二氧化硅(SiO2)为稠化剂,利用硅羟基与纤维素羟基通过氢键物理交联制备了一种新型生物基润滑脂,并对其理化性质、流变特性以及摩擦性能进行了测试,旨在对生物降解型润滑脂的发展进行补充和完善,实现环保型润滑脂的可持续发展。

-

气相SiO2、矿物油由杭州得润宝油脂股份有限公司提供;纤维素由北方世纪(江苏)纤维素有限公司提供。锥入度仪(DFYF-308,大连分析仪器厂);宽温度范围滴点测定仪(ST3498-2,武汉研润科技发展有限公司);扫描电镜(SU 8010,株式会社日立制作所);流变仪(MCR 302,安东帕中国有限公司);四球摩擦试验机(MS-10JS,厦门天机自动化有限公司)。

-

纤维素润滑脂的制备:用电子秤称量320 g矿物油和225 g纤维素,在搅拌下将纤维素逐次加入矿物油中进行充分混匀,后将润滑脂放入三辊研磨机中反复研磨3次,得到质地均一的纤维素润滑脂。

SiO2润滑脂的制备:用电子秤称量550 g矿物油和30 g气相SiO2,将SiO2逐次加入矿物油中经过上述相同的搅拌和研磨操作后得到SiO2润滑脂。

纤维素/SiO2润滑脂的制备:用电子秤称量450 g矿物油,15 g气相SiO2以及165 g纤维素,将SiO2和纤维素逐次加入矿物油经过上述相同的搅拌和研磨操作后得到纤维素/SiO2润滑脂。

应用SPSS 26.0进行单因素完全方差分析比较3种润滑脂的分油率、锥入度以及摩擦学性能差异,用Duncan法进行显著性检验(α=0.05)。

-

对气相SiO2和纤维素表面喷金,用扫描电镜观察样品表面形貌。

-

锥入度是指在规定的负荷、时间和温度条件下锥体落入试样的深度,可以衡量润滑脂的稠度等级。按照GB/T 269—1991《润滑脂和石油脂锥入度测定法》,使用全尺寸的锥体测试3种润滑脂的锥入度,均为2#脂。

-

滴点是在规定的试验条件下,润滑脂在高温下从半固态转换为液态时第1次形成液滴并滴落下来的温度,可判断润滑脂的耐高温性能。采用标准GB/T 3498—2008《润滑脂宽温度范围滴定测定法》测定3种润滑脂的滴点。

-

钢网分油率是指润滑脂在受热条件下析出基础油的趋势,可体现润滑脂在受热条件下的胶体安定性。采用NB/SH/T 0324—2010《润滑脂分油的测定 锥网法》测定润滑脂的分油率。

-

润滑脂的流变特性主要研究润滑脂黏度、剪切应力和剪切应变等性能随温度和剪切速率变化的关系。采用安东帕(奥地利)MCR 302型旋转流变仪,测试过程中选择流变仪的控制应变、控制剪切速率以及控制应力模式。

-

采用四球摩擦试验机测试润滑脂的摩擦学性能,载荷为40×9.806 65 N,转速为1 200 r·min−1,运行时间为60 min。使用光学显微镜观察钢球的磨斑直径。

-

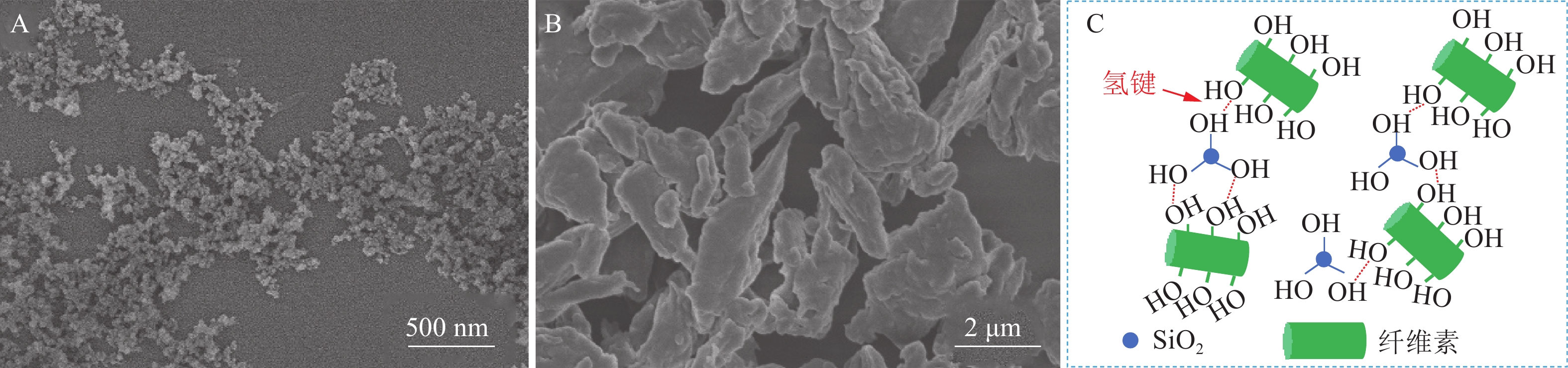

图1A~B为气相SiO2和纤维素的SEM照片,气相SiO2为纳米颗粒状,比表面积大,有利于与基础油的充分接触,具有良好的增稠作用。纤维素呈现微米级的短棒状,其表面的羟基可与SiO2的硅羟基形成氢键交联网络结构(图1C),改善润滑脂的胶体安定性,提升润滑脂的黏温性能和分油率。

-

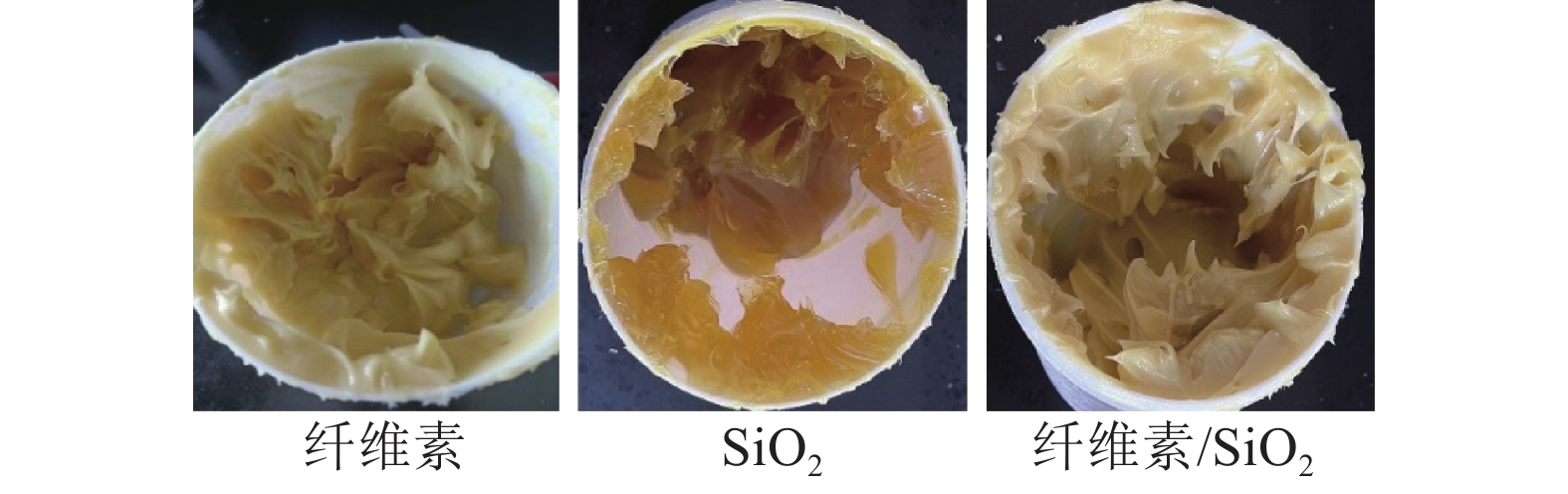

润滑脂锥入度、分油率以及滴点等相关理化性质见表1,3种润滑脂的外观如图2所示。纤维素/SiO2润滑脂的分油率仅为0.6%,较SiO2润滑脂的3.6%有显著下降(P<0.05)。微量的分油可以保持设备润滑,对润滑有利;但过度的分油则会使润滑脂变稠变硬,破坏胶体结构,使润滑脂失去润滑作用,不能满足润滑要求。分油率测试结果表明:纤维素与SiO2的氢键作用赋予了润滑脂优异的胶体安定性。此外,在滴点测试中,纤维素润滑脂和SiO2润滑脂没有滴点(即330 ℃下无滴点),而纤维素/SiO2润滑脂的滴点为327 ℃,这说明纤维素的引入改善了SiO2润滑脂在高温下易失去流动性的缺点。

样品 SiO2添加量/% 纤维素添加量/% 锥入度(0.1 mm) 稠度等级 分油率/% 滴点/℃ 纤维素润滑脂 0 41.3 290 ± 5 a 2# 0.0 ± 0.0 c − SiO2润滑脂 5.2 0 282 ± 2 a 2# 3.6 ± 0.4 a − 纤维素/SiO2润滑脂 2.4 26.2 284 ± 6 a 2# 0.6 ± 0.1 b 327 说明:锥入度和分油率数据为平均值±标准差。同列不同字母表示不同润滑脂间差异显著(P<0.05)。−表示无。 Table 1. Physicochemical properties of greases

-

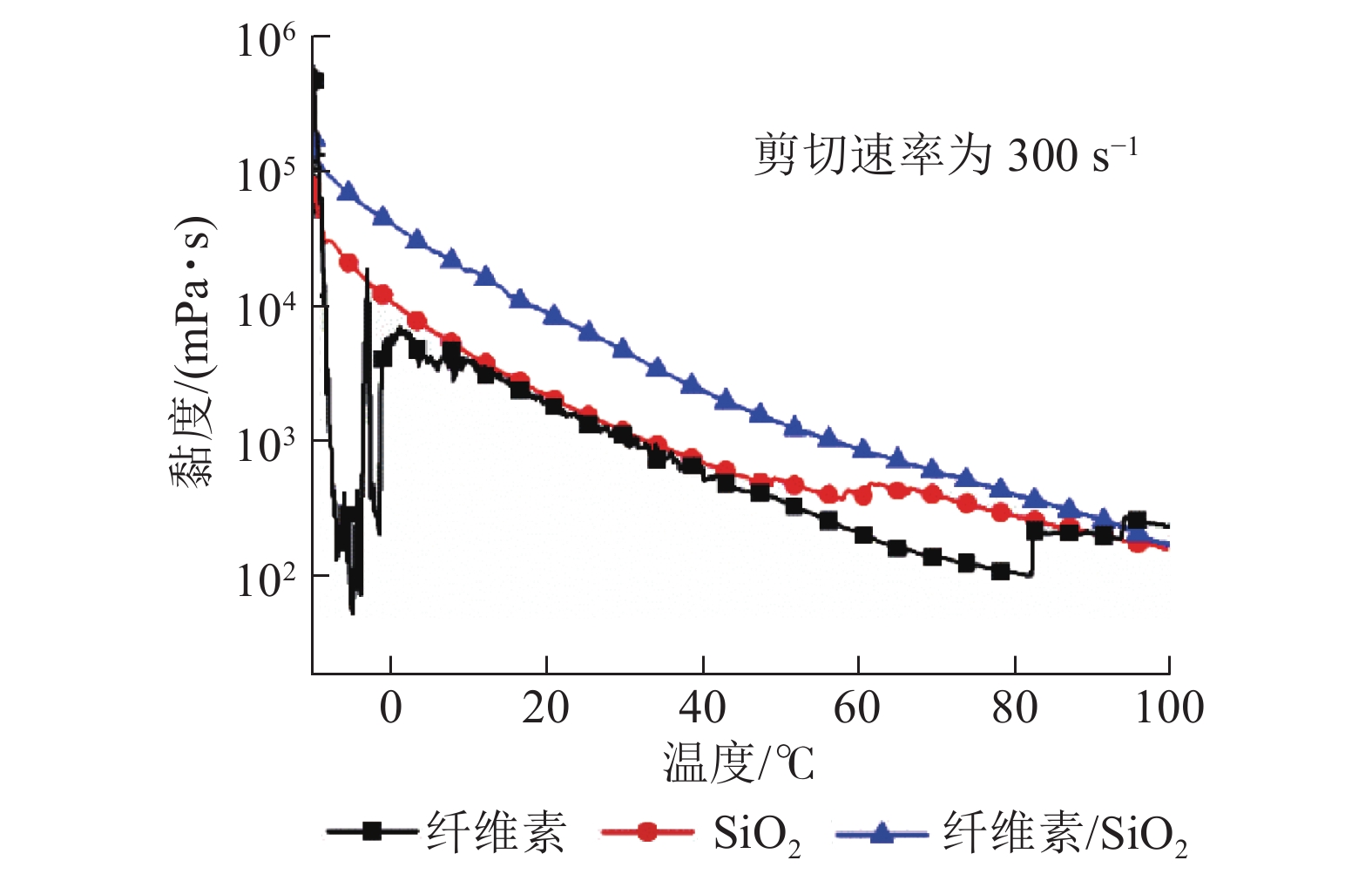

图3为3种润滑脂在剪切速率为300 s−1下的黏度-温度曲线。在0 ℃以下时,纤维素润滑脂的黏度出现了剧烈的抖动,其原因可能是纤维素润滑脂在此温度下发生了冻结,说明纯纤维素润滑脂的低温性能较差。其中,纯纤维素和SiO2润滑脂分别在80 和60 ℃发生黏度升高的现象,这是因为稠化剂与基础油发生了溶胶-凝胶转变,导致黏度升高。纤维素/SiO2润滑脂在温度扫描过程中,其黏度在90 ℃以内始终高于纯纤维素和纯SiO2润滑脂,显示出了优异的黏温性能。

-

图4为3种润滑脂的应变扫描图。可以看出,应变值较小时,润滑脂的储能模量和损耗模量基本维持在一个恒定值,应变超过一定值时(A点),储能模量和损耗模量的线性规律不再保持,两者变化趋于相交。A点为润滑脂线性黏弹区和非线性黏弹区的临界点,其对应的应变为临界应变[26]。储能模量和损耗模量相交的B点称为润滑脂的流动点[27],此时润滑脂的储能模量和损耗模量相等。应变继续增加,损耗模量就开始大于储能模量,表示润滑脂黏性流动所消耗的能量大于弹性变形所存储的能量,呈流动状态[28]。从图4可以看出,纤维素/SiO2润滑脂的流动点所对应的应变值最大,表明润滑脂承受更大的应变时才能由固态转变为流动态。

-

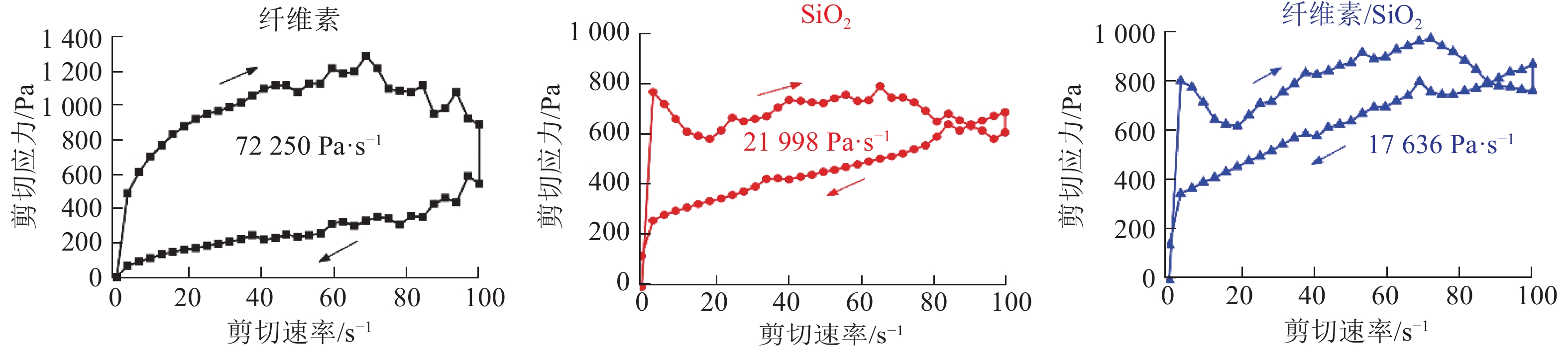

触变环是剪切速率按先增大后减小的规律变化时所形成的剪切应力变化曲线围成的封闭环。表明润滑脂结构的破坏速度显著高于恢复能力,即润滑脂的可恢复性较差。反之,表明润滑脂结构被破坏后的可恢复性越好。图5为3种润滑脂在25 ℃下的触变环曲线。可以看到,纤维素/SiO2润滑脂的面积为17 636 Pa·s−1,小于纯纤维素润滑脂的72 250 Pa·s−1和SiO2润滑脂的21 998 Pa·s−1,表明纤维素与SiO2复配后,润滑脂受剪切作用后的结构恢复性能得到了提升。

-

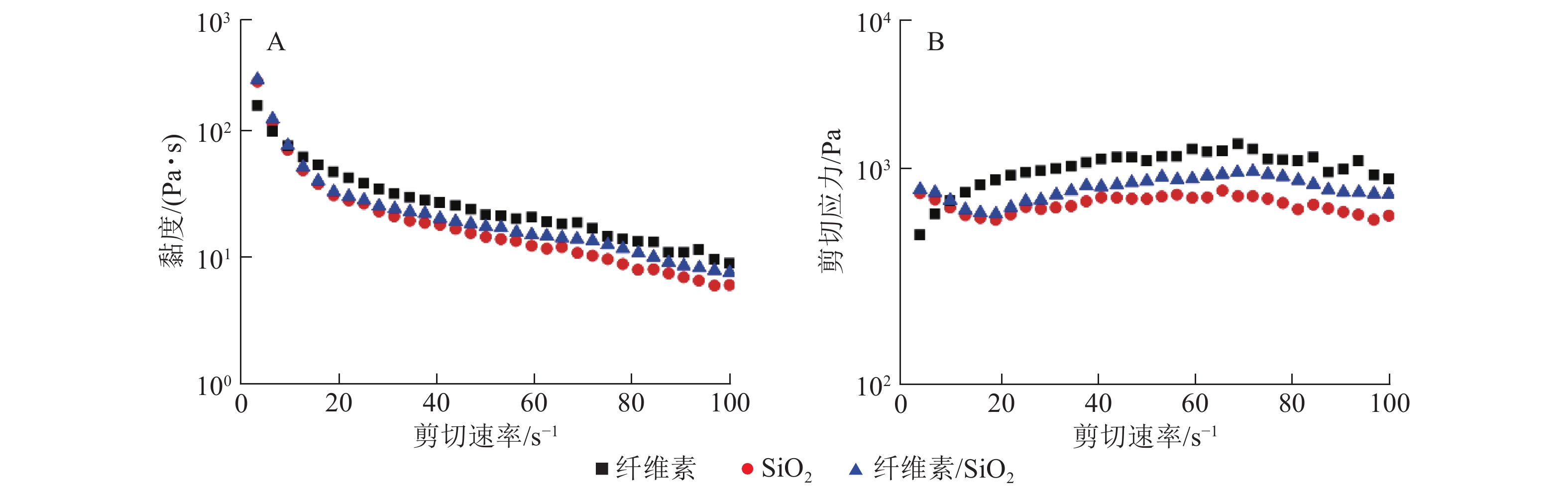

图6A为纤维素、SiO2以及纤维素/SiO2润滑脂黏度的剪切速率扫描图。随着剪切速率的增加,润滑脂的黏度下降,呈现出剪切变稀的特征,并且纤维素和纤维素/SiO2润滑脂的黏度高于SiO2润滑脂。图6B为3种润滑脂剪切应力随剪切速率的变化关系,3种润滑脂的剪切应力随着剪切速率的增加而增加,且纤维素/SiO2润滑脂的剪切应力在剪切过程中是始终高于纯SiO2润滑脂的,表明其能承受的剪切应力更大。

-

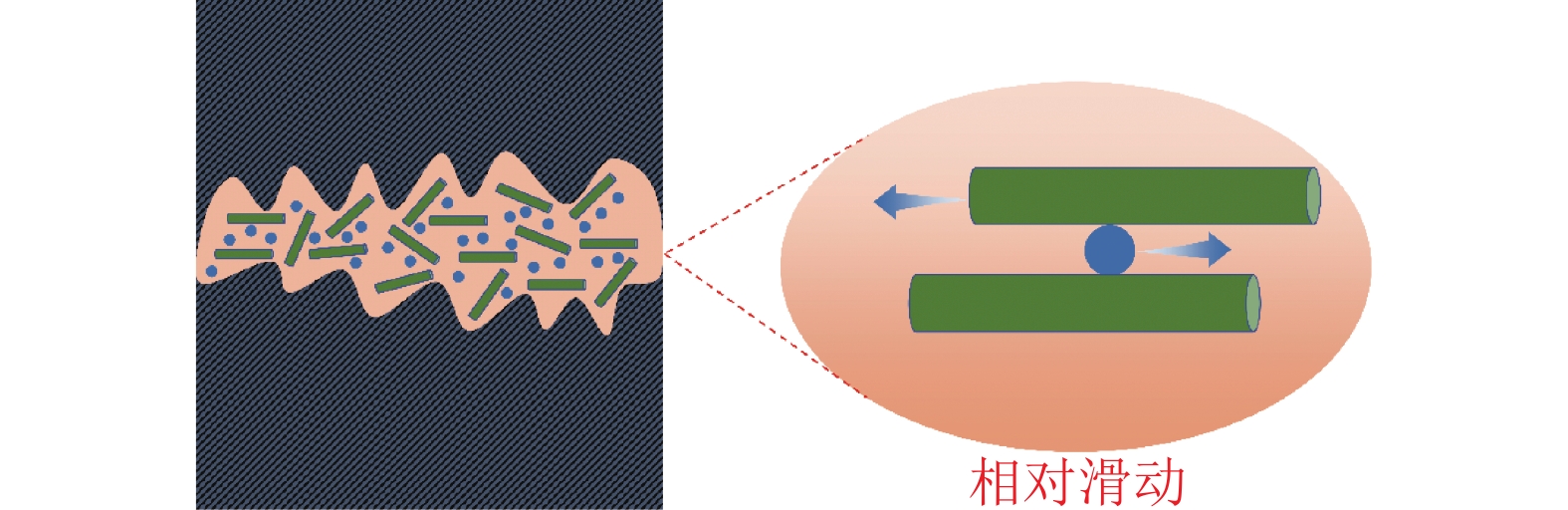

由表2可见:纤维素/SiO2润滑脂的摩擦系数和摩擦力平均值为0.078和3.798 N,显著低于纯纤维素润滑脂的0.093和4.578 N以及SiO2润滑脂的0.095和4.664 N(P<0.05)。其可能的减摩机制如图7所示,相比于纯纤维素润滑脂和SiO2润滑脂,纤维素/SiO2润滑脂在摩擦过程中受剪切力作用,纤维素与SiO2颗粒之间发生相对移动,进而发挥了协效作用,提高了润滑脂的减摩性能。但纤维素/SiO2润滑脂的磨斑直径显著高于纤维素润滑脂和SiO2润滑脂(P<0.05),这可能是因为纤维素与SiO2在相对运动摩擦表面会两相分离,在摩擦副表面发生团聚,产生了更大的磨损体积。

润滑脂样品 摩擦系数 摩擦力/N 磨斑直径/mm 纤维素 0.093 ±0.020 a 4.578 ± 0.200 a 0.633 ± 0.030 c SiO2 0.095 ±0.030 a 4.664 ± 0.300 a 0.744 ± 0.040 b 纤维素/SiO2 0.078 ±0.030 b 3.798 ± 0.200 b 0.848 ± 0.040 a 说明:数据为平均值±标准差。同列不同字母表示不同润滑脂间差异显著(P<0.05)。 Table 2. Friction performance of 3 types of greases

-

黏温性方面,纤维素、SiO2以及纤维素/SiO2润滑脂的黏度均随温度升高而呈现下降趋势,这是因为温度升高,油脂分子的运动加剧,使得粒子间的内摩擦力减小,润滑脂的黏度也随之降低[29]。纤维素与SiO2复配后,两者之间的氢键作用提高了稠化剂结构的强度。因此,纤维素/SiO2润滑脂的黏温性能优于纤维素和SiO2润滑脂。

黏弹性方面,纤维素与SiO2复配后,其流动点对应的应变值最大。这是因为纤维素与SiO2复配后,通过氢键交联构成了一个三维空间网络结构,在其受到应力产生变形直至流动的过程中,会受到氢键作用的约束,只有纤维素/SiO2润滑脂发生更大的变形,才能克服纤维素与SiO2之间的氢键作用力,使之趋于定向,进而流动。

触变性方面,润滑脂在受剪切作用时,其内部的微结构会逐渐被破坏,黏度会逐渐下降,而去除剪切应力后,其黏度又会逐渐恢复。不同的润滑脂在结构恢复中的速度及恢复程度不同,因此触变环的面积可以反映润滑脂结构恢复的快慢[30−31]。纤维素与SiO2复配后,氢键交联网络减缓了润滑脂结构的破坏速度,使得润滑脂受剪切作用后的结构更易恢复。因此,纤维素/SiO2润滑脂的触变环面积最小。

黏剪切性方面,3种润滑脂呈现相似的变化规律,即随着剪切速率的增加,润滑脂的黏度降低,并且在低剪切速率下黏度的下降趋势更为明显,而当剪切速率较高时,黏度趋于稳定。这是因为高剪切速率下,稠化剂粒子间趋于定向,黏度因此也趋于定向,剪切变稀效应逐渐变弱[32],并且由于纤维素之间以及纤维素与SiO2的氢键作用,使得纤维素和纤维素/SiO2润滑脂能够承受更高的剪切速率。

-

本研究利用SiO2表面的硅羟基与纤维素羟基之间的氢键相互作用制备了生物基润滑脂,探究了纤维素、SiO2以及纤维素/SiO2等3种润滑脂的理化性质、流变行为以及摩擦性能。结果表明:①纤维素/SiO2润滑脂的分油率较低,胶体安定性得到提高,并且在327 ℃附近出现了滴点,改善了SiO2润滑脂高温下易失去流动性的缺点。②纤维素/SiO2润滑脂黏温性能和抗剪切能力较SiO2润滑脂得到了提升,且剪切破坏后润滑脂的结构恢复速度变快,结构体系更加稳定。③纤维素/SiO2润滑脂具有较低的摩擦系数和摩擦力,减摩效果较纤维素和SiO2润滑脂有所提升,但磨损体积却较大,抗磨性能有待改进。本研究以天然大宗的纤维素为原料开发出性能可以与商用SiO2润滑脂相媲美的环保型润滑脂产品,具有很强的实际应用前景,有利于生态效益和经济效益的统一,符合国家的可持续发展战略。

Preparation and properties of cellulose/SiO2 grease

doi: 10.11833/j.issn.2095-0756.20230492

- Received Date: 2023-10-04

- Accepted Date: 2024-03-04

- Rev Recd Date: 2024-03-02

- Available Online: 2024-05-22

- Publish Date: 2024-05-22

-

Key words:

- lubricating grease /

- cellulose /

- rheology /

- friction /

- modification

Abstract:

| Citation: | LOU Gaobo, LIU Li’na, FU Shenyuan, et al. Preparation and properties of cellulose/SiO2 grease[J]. Journal of Zhejiang A&F University, 2024, 41(3): 644-650. DOI: 10.11833/j.issn.2095-0756.20230492 |

DownLoad:

DownLoad: