-

园林绿化因在净化空气、美化环境、缓解城市热岛效应等方面作用明显,被现代城市管理者和规划者所重视。随着中国城市化进程的快速发展,城市园林绿化面积大规模增加,产生了大量的园林废弃物。园林废弃物是指园林植物自然凋落或人工修剪所产生的植物残体,主要包括树叶、枝条、残花和果实等[1]。园林废弃物含钾、钠、钙、镁等元素,具有养分含量高,有害成分低,可利用性强等特点[2]。填埋、焚烧等传统的园林废弃物处置方法,不仅会造成营养元素的大量浪费,还会对环境造成二次污染。1万株行道树产生的园林垃圾达600 t·a-1,而北京、广州、上海等地产生10万t·a-1以上的园林废弃物[3]。面对如此庞大的园林废弃物产量,园林废弃物资源化利用在未来将成为发展低碳城市和低碳经济的一种必然选择。生物质炭(biochar)是指生物质在缺氧或者绝氧条件下热解所产生的含碳丰富的固体物质[4],通常具有比表面积大,含碳量高,营养元素丰富,性质稳定等特点。近年来,因其在固碳减排、土壤改良和环境污染治理等领域中的潜在应用价值而受到广泛关注,生物质热解炭化技术为园林废弃物的资源化利用提供了新的技术途径。生物质炭的性质通常由生物质原材料和热解条件所决定,不同原材料和热解条件下制备的生物质炭结构特性存在较大差异。如ALEXIS等[5]发现:生物质炭中营养元素的组成含量和生物质原材料中元素的含量呈线性相关。热解温度的增加会导致生物质炭的产率降低,孔隙结构更发达,比表面积增大,表面官能团数量减少,芳香度和疏水性增强等[6-7]。一些研究发现,生物质炭并不都是温度越高比表面积越大,如杨兴等[8]研究发现:烟秆炭在500 ℃时比表面积达到最大值,当热解温度继续升至600 ℃时比表面积开始降低。生物质炭在pH值、孔隙结构、表面官能团等理化特性上的差异可能会影响其在农业生产和生态修复方面的作用,如碳酸钙(CaCO3)和焦磷酸钙(Ca2P2O7)等矿物组分含量高的生物质炭对溶液中重金属吸附效果好,主要是因为溶液中重金属离子与灰分中的可溶性盐组分形成了沉淀[9]。李瑞月等[10]研究发现:小麦Triticum aestivum和水稻Oryza sativa秸秆炭对溶液中铅离子(Pb2+)的吸附容量比玉米Zea mays秸秆炭高,这与玉米秸秆炭的碳酸盐、磷酸盐等灰分以及二氧化硅等无机矿物含量较高有关。因此,研究热解温度和原材料对生物质炭特性的影响对生物质炭的推广应用显得尤为重要。生物质炭制备原料来源广泛,以农业秸秆,动物尸体、粪便等作为热解原材料的研究都有报道[11-13],但以园林绿化废弃物制备生物质炭的相关报道较少,总体上仍处于起步阶段[1]。因此,本研究以法国梧桐Platanus orientalis,桂花Osmanthus fragrans,红叶石楠Photiniax fraseri和樟树Cinnamomum camphora等4种中国南方城市典型园林植物废弃生物质为原材料,分别在350,500和650 ℃条件下热解制备生物质炭,对比分析生物质炭的产率、元素组成、比表面积、孔隙结构等理化性质,旨在探讨园林废弃物生物质原材料及热解温度对生物质炭性能的影响,以期为园林废弃物的资源化利用,以及园林废弃物生物质炭在农业生产和生态修复等领域的推广应用提供理论依据和技术支撑。

HTML

-

本研究所用原材料为法国梧桐、桂花、红叶石楠和樟树,均为杭州市园林绿化修剪凋落物,采集时间为2015年11月。将植物凋落物分为枝条和叶片2个部分,置于烘箱中在65 ℃条件下烘干至恒量。取部分烘干材料粉碎,过40~60目筛备用。原材料工业分析和元素分析结果见表 1。

原材料 工业分析/% 元素分析/% 水分 挥发分 灰分 固定碳 碳 氢 氮 硫 氧 法国梧桐叶片fy 8.95 76.40 7.33 7.32 46.43 5.21 0.83 0.23 47.30 桂花叶片gy 3.50 89.49 5.21 1.81 46.73 6.22 1.32 0.17 45.56 红叶石楠叶片hy 5.29 82.32 6.77 5.62 45.69 5.93 0.98 0.10 47.30 樟树叶片xy 5.86 81.35 8.48 4.31 45.91 5.91 1.56 0.15 46.47 法国梧桐枝条fz 3.03 89.60 1.40 5.96 45.13 5.92 0.42 0.04 48.49 桂花枝条gz 3.78 88.01 1.71 6.50 45.75 6.06 0.40 0.03 47.76 红叶石楠枝条hz 3.91 85.82 2.10 8.17 44.46 5.89 0.47 0.02 49.16 樟树枝条xz 7.94 83.50 3.21 5.35 44.80 5.90 0.49 0.03 48.78 说明:氧质量分数由差减计算得到[5] Table 1. Proximate and ultimate analyses of raw biomass materials.

-

分别称取一定量烘干处理后的生物质原材料于热解炉中,使热解炉内保持在缺氧条件下。设置升温速率为25 ℃·min-1,到达最终温度(350,500和650 ℃)后停留2 h,使样品充分热解反应。热解完成后,生物质炭自然冷却至室温后烘干称量。共制得8种生物质炭,分别为不同温度热解所得的法国梧桐叶片炭(fy),桂花叶片炭(gy),红叶石楠叶片炭(hy),樟树叶片炭(xy),法国梧桐枝条炭(fz),桂花枝条炭(gz),红叶石楠枝条炭(hz)和樟树枝条炭(xz)。将生物质炭研磨分别过10和100目筛后备用。

-

生物质炭产率按以下公式获得:产率(%)=生物质炭的质量/生物质原材料的烘干质量×100%。灰分含量采用干烧法测定,称取1.000 0 g生物质炭置于恒量坩埚中,放入马弗炉中在750 ℃下灼烧6 h,冷却至室温后根据前后质量计算生物质炭的灰分质量分数[14]。挥发分质量分数采用国家标准GB/T 212-2001《煤的工业分析方法》中规定的方法,称取1.000 0 g生物质炭,置入恒量的瓷坩埚中,迅速放入预先升温至(900±10)℃的马弗炉中,7 min后从炉内取出坩埚,放在空气中冷却约5 min,移入干燥器中冷却约20 min后称量。根据样品灼烧前后质量差计算生物质炭的挥发分质量分数[15]。采用元素分析仪(Vario ELⅢ,Elementar公司,德国)测定生物质炭中碳、氢、氮和硫元素的质量分数,计算得出氧元素质量分数。采用傅里叶变换红外光谱仪(IS-10系列,Nicolet公司,美国)测定生物质炭的表面官能团。采用扫描电镜(SU-8010,日立公司,日本)测定生物质炭表面的孔隙结构和形态特征。采用能谱仪(Aztec X-MaxN,牛津仪器公司,美国)测定生物质炭表面某点位的元素组成。

-

采用Excel 2007进行数据处理,运用SPSS 21.0软件中的单因素方差分析(one way ANOVA)和最小显著差法(LSD)进行显著性(P<0.05)统计检测,利用Origin 8.5制图。

1.1. 试验材料

1.2. 生物质炭的制备

1.3. 生物质炭的产率及理化性质测定

1.4. 数理统计分析

-

热解温度对生物质炭产率的影响如图 1所示。随着热解温度的升高,生物质炭的产率均呈下降趋势,且在350~500 ℃下降幅度较大。其中,桂花叶片炭在350~500 ℃温度段的下降幅度最大,高达37.78%。当热解温度为350 ℃时,法国梧桐叶片炭产率最高(57.28%),樟树叶片炭次之(54.22%),法国梧桐枝条炭的产率最低(37.70%),桂花和红叶石楠同部位之间炭产率无显著差异(P>0.05)。但温度升高至500 ℃,红叶石楠叶片炭和枝条炭的产率高于桂花同部位产率。热解温度继续升高至650 ℃,法国梧桐叶片炭和樟树叶片炭产率显著高于(P<0.05)其他生物质炭,法国梧桐枝条炭的产率仍为最低(22.38%)。相同热解温度下,同种园林废弃物叶片炭产率高于枝条炭。所有生物质炭中,法国梧桐枝条炭产率最低,叶片炭产率最高。

-

由表 2可以看出:随着热解温度的升高,生物质炭的灰分逐渐增加。650 ℃制备的红叶石楠叶片炭灰分质量分数最高,显著高于(P<0.05)其他生物质炭,约为350 ℃制备的桂花枝条炭的5.5倍。挥发分质量分数逐步下降,其中,桂花叶片炭的挥发分从350 ℃的62.73%降至650 ℃的27.56%,变化幅度最大。固定碳逐渐增加,650 ℃制备的法国梧桐枝条炭固定碳质量分数最高,为61.83%,较350 ℃增加了34.21%。350 ℃制备的叶片炭固定碳质量分数显著低于(P<0.05)其他生物质炭。相同热解温度下,同种园林废弃物叶片炭的灰分、挥发分均高于枝条炭,固定碳质量分数则低于枝条炭。

生物质炭 工业分析/% 元素分析/% 原子比 灰分 挥发分 固定碳 碳 氢 氮 硫 氧 H/C O/C (O+N)/C fy350 13.74±1.1 e 57.40±0.4 b 25.03±0.6 h 61.10±0.0 l 4.51±0.1 cde 1.44±0.0 c 0.20±0.0 d 32.74±0.1a 0.89 0.40 0.42 fy500 16.84±2.4 d 38.24±1.1 de 40.52±2.2 ef 65.14±1.7 ij 3.10±0.0 f 1.27±0.1 d 0.20±0.0 de 30.29±1.8 b 0.57 0.35 0.37 fy650 20.84±0.4 b 29.57±1.7 ghi 46.20±2.9c d 67.10±1.4 jh 1.89±0.1 hi 0.93±0.1 efgh 0.17±0.0 f 29.92±1.4 b 0.34 0.33 0.35 gy350 8.74±0.3 hi 62.73±2.0 a 24.37±1.9 h 66.23±0.3 ghi 5.17±0.3 a 2.21±0.1 b 0.26±0.0 c 26.13±0.7 cd 0.94 0.30 0.32 gy500 14.79±0.4 e 30.36±1.2 hi 50.89±1.4 a 68.02±0.0 fg 2.98±0.0 f 2.23±0.0 b 0.32±0.0 a 26.45±0.1 cd 0.53 0.29 0.32 gy650 15.85±0.2 d 27.56±1.7 hi 50.82±1.7 a 70.17±0.5 e 2.00±0.0 ghi 1.47±0.1 c 0.29±0.0 b 26.07±0.4 c 0.34 0.28 0.30 hy350 14.23±0.7 e 56.67±10.6 b 24.64±10.6 h 61.72±2.2 kl 4.71±0.3 bc 1.52±0.1 c 0.03±0.0 j 32.02±2.6 ab 0.92 0.39 0.41 hy500 19.91±0.3 b 36.76±0.7 de 38.96±0.6 f 64.06±0.7 j 2.89±0.0 f 1.52±0.0 c 0.03±0.0 j 31.50±0.8 ab 0.54 0.37 0.39 hy650 22.78±0.2 a 32.71±1.1 fgh 40.73±1.0 ef 63.94±0.4 j 1.81±0.1 i 1.05±0.1 ef 0.05±0.0 ij 33.16±0.4 a 0.34 0.39 0.40 xy350 11.93±0.3 f 59.40±1.3 ab 24.50±1.5 h 61.98±1.2 kl 4.85±0.0 bc 2.41±0.0 a 0.17±0.0 ef 30.59±1.3 b 0.94 0.37 0.40 xy500 18.28±1.4 c 38.89±2.5 def 38.44±1.7 f 63.29±0.1 jk 2.87±0.0 f 2.25±0.1 b 0.15±0.0 fg 31.44±0.3 ab 0.54 0.37 0.40 xy650 18.28±0.7 c 33.64±0.8 efg 42.44±0.9 def 66.00±0.2 hi 1.88±0.0 hi 1.51±0.1 c 0.13±0.0g 30.48±0.3 b 0.34 0.35 0.37 fz350 4.22±0.1 l 45.95±1.8 c 46.07±1.8 cd 70.34±0.3 de 4.36±0.0 ed 1.01±0.0 efg 0.08±0.0 h 24.21±0.4 de 0.74 0.26 0.27 fz500 6.01±0.1 k 31.29±3.1 ghi 58.86±3.0 a 78.79±0.1 b 3.12±0.1 f 1.08±0.0 e 0.09±0.0 h 16.92±0.2 h 0.48 0.16 0.17 fz650 6.96±0.3 jk 26.71±4.3 i 61.83±4.2 a 82.81±0.2 a 2.11±0.0 gh 0.86±0.0 gh 0.08±0.0 hi 14.15±0.2 i 0.31 0.13 0.14 gz350 4.17±0.4 l 47.90±1.9 c 44.06±1.8 de 72.14±0.5 d 4.63±0.0 bc 0.90±0.0 fgh 0.06±0.0 ghi 22.28±0.6 e 0.77 0.23 0.24 gz500 6.71±0.5 jk 32.35±2.5 fgh 57.30±2.7 a 79.36±1.1 b 3.11±0.1 f 1.03±0.1 efg 0.06±0.0 ghi 16.43±0.9 h 0.47 0.16 0.17 gz650 6.83±0.4 jk 28.72±4.3 ghi 59.00±4.4 a 82.74±1.7 a 2.17±0.0 g 0.80±0.1 h 0.08±0.0 hi 14.21±1.8 i 0.32 0.13 0.14 hz350 6.05±0.2 k 45.38±2.7 c 45.34±2.5 de 67.95±0.8 fg 4.27±0.0 e 0.94±0.0 efgh 0.06±0.0 hij 26.78±0.8 c 0.75 0.30 0.31 hz500 8.15±0.7 ij 29.77±1.7 ghi 59.07±0.6 a 76.76±0.1 c 3.04±0.0 f 1.03±0.0 efg 0.06±0.0 hij 19.12±0.2 fg 0.47 0.19 0.20 hz650 9.56±0.7 jh 27.46±5.3 hi 58.24±4.8 a 78.82±0.8 b 2.07±0.0 gh 0.90±0.0 fgh 0.05±0.0 ij 18.17±0.8 gh 0.31 0.17 0.18 xz350 7.44±0.5 jk 55.86±3.1 b 33.85±2.0 g 69.58±0.1 ef 4.53±0.2 d 1.02±0.1 efg 0.05±0.0 ij 24.83±0.0 cd 0.78 0.27 0.28 xz500 10.42±0.4 g 39.98±2.4 d 46.33±1.7 cd 75.87±0.1 c 2.92±0.1 f 0.95±0.0 efgh 0.04±0.0 j 20.22±0.2 f 0.46 0.20 0.21 xz650 11.44±0.3 f 33.75±3.2 efg 51.42±2.3 b 69.58±0.1 ef 4.53±0.2 cd 1.02±0.1 efg 0.05±0.0 ij 24.83±0.0 cd 0.78 0.27 0.28 说明:同列不同字母代表处理间差异显著(P<0.05) Table 2. Proximate and ultimate analyses of biochars derived from woody green wastes

热解后得到的生物质炭的碳(C)质量分数较原材料增加,氢(H)和氧(O)质量分数降低(表 1和表 2),并且随着热解温度的升高生物质炭的碳质量分数逐渐增加,氢和氧质量分数逐渐降低,进而导致H/C和O/C降低。枝条炭H/C高于叶片炭,叶片炭O/C高于枝条炭。其中,法国梧桐枝条炭和红叶石楠枝条炭H/C较低,法国梧桐叶片炭O/C最高。生物质炭的碳质量分数为61.09%~83.97%,其中桂花枝条炭的碳质量分数较高。氮(N)元素随着温度的升高有降低趋势,叶片炭在650 ℃时下降幅度大于枝条炭,樟树叶片炭在各温度段全氮质量分数均为最高。但热解温度对硫元素的影响较小,桂花叶片炭在各温度段全硫质量分数均为最高。

-

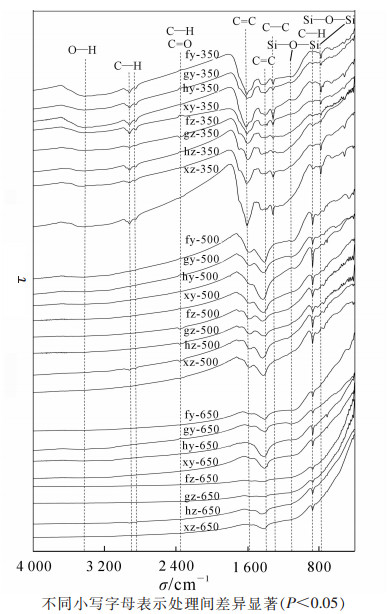

利用傅里叶红外光谱仪(FTIR)分析生物质炭表面官能团,结果如图 2所示。较低热解温度制备的生物质炭表面形成了多种官能团。随着热解温度的升高,官能团的种类和数量逐渐减少。当热解温度为350 ℃时,波数3 200~3 500 cm-1出现酚羟基或醇羟基的O—H伸缩振动峰[16],波数2 920 cm-1和2 852 cm-1处出现烷烃中的C—H伸缩振动峰[17],波数2 380 cm-1处出现芳香族C—H和C—O振动吸收峰[18],波数1 596 cm-1和1 440 cm-1出现芳香族C=C骨架伸缩振动峰[19],波数1 317 cm-1处出现芳香族C—C伸缩振动峰[16],波数885 cm-1处出现芳香族C—H伸缩振动峰[16],且在1 030 cm-1和797 cm-1波段有Si—O—Si振动吸收峰检出[20-21]。当热解温度升高至500 ℃时,芳香族C=C(1 440 cm-1)骨架振动和芳香族C—H(885 cm-1)振动峰明显增强,Si—O—Si振动吸收峰(1 030 cm-1)无明显变化,其他吸收峰的强度均明显减弱。热解温度达到650 ℃,所有吸收峰强度均明显减弱,其中C=C伸缩振动峰(1 596 cm-1)受热解温度影响最明显,但Si—O—Si振动吸收峰(1 030 cm-1)无明显变化。

Figure 2. FTIR spectra of biochars derived from derived from woody green wastes pyrolyzed at different temperatures

相同制备温度下的生物质炭表面官能团组成相似,但因原材料不同存在一定的差异。当热解温度为350 ℃时,樟树枝条炭官能团最为丰富,波峰最强,且在1 596 cm-1处的芳香族C=C峰明显强于其他生物质炭,法国梧桐枝条炭表面存在脂肪类C—H和C=O官能团(2 380 cm-1);热解温度上升到500 ℃,枝条炭均存在脂肪类C—H和C=O官能团(2 380 cm-1),红叶石楠叶片炭在885 cm-1处的芳香族C—H伸缩振动峰强度明显强于其他生物质炭;热解温度达到650 ℃,仅红叶石楠枝条炭表面在还存在微弱的C—H伸缩振动(2 920 cm-1和2 852 cm-1)。此外,不同温度条件下制备的红叶石楠叶片炭在1 440 cm-1处的芳香族C=C伸缩振动峰信号均为最强。

-

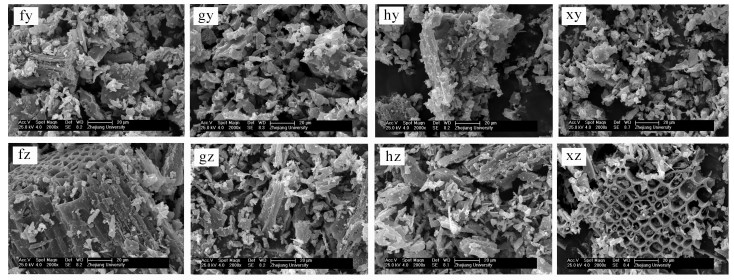

对生物质炭的孔隙进行分析,可以直观地了解不同原材料制备的生物质炭的结构特征。选取在500 ℃条件下制备的生物质炭进行电镜扫描和比表面积测定,结果如图 3所示。法国梧桐叶片炭和枝条炭均保留了生物质原有的骨架,樟树和法国梧桐枝条炭横截面呈蜂窝状,表面均有明显的管束结构,且排列均匀。经检测,樟树枝条炭和法国梧桐枝条炭的比表面积分别达49.05和38.25 m2·g-1,桂花枝条炭和法国梧桐叶片炭的比表面积也可达24.98和18.72 m2·g-1。红叶石楠枝条炭、桂花叶片炭、红叶石楠叶片炭和樟树叶片炭表面粗糙,呈颗粒状,孔隙结构不明显,其比表面积依次为7.58,7.64,10.24和6.50 m2·g-1。采用能量色散X射线分析不同生物质炭表面的元素组成及质量分数,结果如表 3所示。叶片炭矿质元素组成多于枝条炭,其中,樟树叶片炭元素组成最丰富,并检出有铝和铁等元素存在。红叶石楠叶片炭的钾、钙、磷和镁元素质量分数分别为3.95%,7.09%,0.68%和0.84%,高于其他生物质炭。法国梧桐叶片炭的硅质量分数最高,为1.73%。与叶片炭相比,枝条炭的碳质量分数较高,均在85.00%以上。其中,桂花枝条炭高达90.28%。

生物质炭 碳/% 氧/% 镁/% 硅/% 磷/% 氯/% 钾/% 钙/% 硫/% 铝/% 铁/% fy 80.23 10.71 0.41 1.73 0.19 0.11 1.42 5.00 0.21 - - gy 82.29 8.30 0.42 0.75 0.40 0.26 2.72 4.37 0.50 - - hy 74.99 12.29 0.84 0.17 0.68 - 3.95 7.09 - - - xy 78.25 10.48 0.54 0.81 0.54 - 2.33 5.79 0.45 0.37 0.45 fz 90.26 6.16 - - 0.24 - 0.90 2.45 - - - gz 90.28 5.81 - 0.36 0.35 - 1.23 1.96 - - - hz 86.98 7.42 - 0.28 0.34 - 0.84 4.14 - - - xz 85.56 7.99 0.41 - 0.50 - 2.22 3.33 - - 说明:“-”代表未检测出 Table 3. Elemental composition of certain site at surface of biochars pyrolyzed at 500 ℃ determined by EDS

2.1. 生物质炭的产率

2.2. 生物质炭的工业分析和元素分析

2.3. 生物质炭红外光谱分析

2.4. 生物质炭孔隙结构及表面能谱分析

-

生物质热裂解是一个极其复杂的热化学过程,主要包括脱水、裂解和炭化3个反应阶段[20]。一般来说,原材料和热解温度不仅影响生物质炭的产率,而且还与生物质炭的元素组成和结构特性等密切相关[22]。本研究显示:原材料和热解温度直接决定了生物质炭的特性,主要表现在生物质炭的产率、元素组成、官能团种类和质量分数、物理结构等方面。

-

本研究中,随着热解温度从350 ℃升高到650 ℃,生物质炭的产率均呈下降趋势,且在350~500 ℃温度段变化较明显。高凯芳[15]研究亦发现:稻秆和稻壳生物质炭的产率随热解温度升高而降低,且在300~500 ℃温度段生物炭质量损失最大。这可能是由于热解的生物质原料主要由纤维素、半纤维素、木质素等有机组分组成,半纤维素和纤维素在200~350 ℃条件下基本完全分解,而木质素的分解温度一般为280~500 ℃[23],因此,350~500 ℃温度段生物质炭产率大幅度下降。还有研究认为,低温阶段(300~400 ℃)生物质原材料的纤维素等组分对生物质炭的产率有明显影响,热解温度超过400 ℃以后灰分对生物质炭的产率的影响更大,而且原材料的灰分含量对生物质炭产率的影响要大于木质素含量的影响[25]。相同热解温度下,高灰分含量和高木质素含量的生物质原材料制备的生物质炭产率较高[22, 24-25]。

-

通常利用红外光谱确定生物质炭表面各种官能团变化特征。热解温度从350 ℃上升到500 ℃的过程中,生物质中纤维素和木质素的羟基发生断裂,脱水反应逐渐完成,生物质炭表面的酚羟基和醇羟基也随之消失;纤维素等有机质的分解造成烷基基团(烷烃中的C—H伸缩振动峰)逐渐消失,生物质炭的芳香化程度增强[16-17, 22]。随着生物质炭的脱氧反应加剧,芳香族C—C和C—H伸缩振动峰在500 ℃时达到最强,此时的生物质炭以芳香骨架为主,而且可能存在羟基、芳香醚等官能团[16, 26]。Si—O—Si振动吸收峰是因为热解过程中生物质形成的灰分中含有硅酸盐所致[20],然而枝条炭在此处并没有强烈信号,这可能与原材料组成有关。350 ℃热解条件下,樟树枝条炭表面官能团含量最多。其中,芳香族C=C(1 596 cm-1),C—C伸缩振动峰(1 317 cm-1)和Si—O—Si振动吸收峰(797 cm-1)强度较大,说明350 ℃制备的樟树枝条炭芳香化程度较强,存在羟基、芳香醚等官能团,有机碳组分和无机矿物二氧化硅相对较多[27]。总的来说,生物质原材料对生物质炭表面的官能团组成影响较大,但热解温度对樟树叶片炭的影响不大。

-

生物质炭的多孔结构一方面是由于生物质本身存在海绵结构[20],另一方面是随着温度的升高,木质素热解时挥发分依次析出,大量挥发分的析出促使木质素内生成了许多气泡与气孔,这些气泡由生长到破裂,形成了生物质炭的孔隙结构[28]。500 ℃制备的园林废弃物炭均保留了生物质的骨架结构,与叶片炭相比,枝条炭具备更明显的孔隙结构,管束排列明显。一些研究发现:由于热解温度升高,木质素发生软化熔融,堵塞气孔,导致生物质炭孔隙结构变差[29],这可能是叶片炭孔隙结构较差的原因。谭洪等[30]研究发现:以芸香Ruta graveolens木为材料在300 ℃下热解制备的生物质炭具有明显的筋状结构,而同温度下制备的稻壳炭表面则呈类似鳞状,表明生物质原材料对生物质炭孔隙结构有明显影响。多孔结构会使生物质炭具有较大的比表面积和较强的吸附特性[31],法国梧桐和樟树枝条炭表面呈蜂窝状,管束清晰,孔隙结构发达,比表面积较大,此特性使其作为吸附剂在水体和土壤污染物修复方面更有应用前景[32]。

-

园林废弃物主要由纤维素、木质素和半纤维素和无机成分组成,生物质各组分会在热解过程中发生脱羟基、脱水等化学反应,导致生物质炭的碳含量增加,氢和氧含量降低,硅、钙、镁等无机物富集形成灰分[16, 23]。本研究发现:由灰分质量分数高的叶片制备的生物质炭灰分质量分数也高,说明生物质炭灰分也受到原材料组成的影响。H/C,O/C和(O+N)/C分别代表了生物炭的芳香性、亲水性和极性,其比值的改变说明生物质炭的芳香性、亲水性和极性受到影响[15]。高温下H/C,(O+N)/C和O/C的降低说明生物质炭的芳香性加剧,亲水性和极性减弱,高温热解制备的生物质炭更稳定,适合作为添加剂施入土壤,用以减少温室气体排放,增加土壤的固碳容量。650 ℃制备的红叶石楠枝条炭挥发分含量最低,且H/C最小稳定性最强,而由于生物质炭的挥发分含量与氧化氮累计排放量值间存在正相关关系[33],高温条件下生物质炭的挥发分含量一般会减少,因此未来可通过控制生物质炭的制备温度达到抑制氧化氮等温室气体排放的作用。

植物生物质热解制备的生物质炭,往往保留了植物生长所需的大部分营养元素[34]。元素分析结果表明,温度对硫和氮等营养元素的影响较小,不同原材料制备的生物质炭之间元素组成和质量分数差异较大,原材料对生物质炭的营养元素组成比热解温度影响更明显。本研究结果发现:灰分质量分数高的叶片炭矿质元素组成比枝条炭复杂,矿质元素质量分数较高。ALEXIS等[5]研究也发现:原材料灰分含量越高,其制备的生物质炭营养元素含量越丰富。此外,生物质炭施入土壤可以显著提高土壤的总磷含量,增加土壤速效钾含量等[35]。据土壤普查资料显示,当前68%的农田为中低产地,营养元素缺乏,如全部旱地和60%的水田缺磷,耕地中58%缺钾,严重阻碍农业经济发展[36]。500 ℃制备的红叶石楠叶片炭的钾、钙、镁和磷元素质量百分比明显高于其他生物质炭,可将其作为土壤调理剂,用于补充植物生长必需的主要营养元素,既可以提高农作物产量和品质,又能够降低农民生产投入成本,具有较好的应用前景。

3.1. 原材料及热解温度对生物质炭产率的影响

3.2. 原材料及热解温度对生物质炭表面特性的影响

3.3. 原材料对生物质炭物理结构的影响

3.4. 原材料及热解温度对生物质炭化学成分及元素组成的影响

-

热解温度对生物质炭理化性质有决定性作用,随着热解温度升高,生物质炭的产率、挥发分、亲水性和极性降低;灰分、固定碳质量分数和芳香性增强;表面官能团逐渐减少。

原材料对生物质炭的理化性质也有极大影响。灰分质量分数高的原材料制备的生物质炭产率较高。相同热解温度下,同种园林废弃物叶片炭的产率和灰分、挥发分、矿质元素质量分数均高于枝条炭,固定碳质量分数则低于枝条炭。樟树枝条炭和法国梧桐枝条炭孔隙结构较发达,比表面积较大。

本研究结果表明:不同热解温度和园林废弃物制备的生物质炭在理化性质上存在明显差异,该研究可为典型园林废弃物生物质炭的制备工艺优化提供数据参考。对于这种园林废弃物制备的生物质炭在土水环境修复、提高土壤肥力等方面的功能还需进一步研究,为其更科学、合理地应用提供技术依据。

DownLoad:

DownLoad: