-

自然界许多生物能对环境变化做出反应,改变自身的颜色,这种颜色被称为结构色[1−2],是由光子晶体的微结构周期性排列,通过光干涉效应产生的[3]。这种根据环境产生颜色的功能可用于智能材料的开发,在防伪商标[4]、化学传感[5]和生物技术[6]等领域具有广阔的应用潜力。纤维素纳米晶体(CNC)可由木质纤维素经强酸水解法、酶水解法、磷酸水热法和2, 2, 6, 6 -四甲基哌啶氧化物(TEMPO)氧化法等[7]方法获得,具有精细的纳米结构、丰富的表面活性基团、优异的力学性能以及可再生和降解的特点[8−9],是一种重要的生物基纳米材料。CNC悬浮液达到某一临界浓度时,会自发进行有序排列,形成手性向列相液晶结构[10]。通过溶剂蒸发的方法制备CNC薄膜,手性向列相结构得以保留。随着溶剂的蒸发,CNC的浓度逐渐增大,螺距减小,最大反射光波长(λmax)蓝移至可见光范围,赋予薄膜结构色[11],因此,CNC是一种生物质光子晶体材料,成为近期的研究热点。

CNC光子材料的螺距会随环境湿度变化,从而影响其光学性质及结构色,具有湿度敏感性[12−15]。纯CNC液晶薄膜,由于CNC的刚性,非常脆,还存在薄膜湿度灵敏度低,结构色变化不均匀的缺点。为了提高CNC液晶薄膜的韧性,YOUSSEF等[16]将聚乙二醇(PEG)和CNC自组装,形成了具有均匀结构色且柔性的复合膜,在不同的湿度条件下,复合膜的结构色发生可逆均匀改变,由于PEG与CNC良好的相容性,在提升液晶薄膜韧性的基础上,PEG还提升了薄膜的湿度敏感性。研究者们向CNC体系中引入水溶性聚合物,如PEG[12]、聚乙烯醇(PVA)[17]、水性聚氨酯(WPU)[18]等,研究复合CNC液晶薄膜力学和湿度响应行为。

目前针对CNC复合薄膜湿度响应方面的研究主要关注于湿度-结构-变色之间的构效关系,对CNC复合薄膜湿度响应速度和重复性研究不够深入,因此,本研究以CNC为原料,通过将PEG与CNC共组装,制备具有手性向列结构的虹彩色PEG/CNC复合液晶薄膜,系统考察PEG质量分数对复合液晶薄膜的微观结构、显色、力学性能以及吸湿行为的影响,通过饱和电解质溶液控制环境湿度,重点考察复合薄膜在不同湿度下的吸湿-解湿过程和性能变化,阐明PEG/CNC复合薄膜湿度响应机制,为制备低成本、可重复使用和高灵敏度的PEG/CNC复合薄膜湿度传感器提供理论基础。

-

木质纤维素纳米晶体(CNC,美国缅因大学),从木浆中提取并通过硫酸水解,固含量为10.3% (质量分数),含质量分数为1.1%的硫和钠离子;PEG 4000、氯化锂(LiCl)、氯化钠(NaCl)、溴化钠(NaBr)和氯化镁(MgCl2)均为分析纯。

-

首先按照所需比例称取一定质量的CNC与PEG,加入一定量的去离子水稀释后,用玻璃棒搅拌2 min,再用超声波细胞粉碎机超声5 min,得CNC与PEG的混合液,混合液的流动性较好,在剪切速率为1 s−1时,黏度为0.01~0.02 Pa·s。随后,将混合液倒入塑料培养皿,置于35 ℃烘箱中干燥约36 h,得PEG/CNC液晶薄膜。在溶液浇筑过程中控制固含量,控制所得复合薄膜的厚度约为150 μm。制备CNC悬浮液质量分数分别为3%、5%和7%的CNC液晶薄膜,分别标记为3%CNC、5%CNC和7%CNC; PEG/CNC复合体系中,CNC悬浮液质量分数为5%,添加的PEG质量分数分别为0%、5%、10%和15%,分别标记为5%CNC 、5%CNC+5%PEG、5%CNC+10%PEG和5%CNC+15%PEG。

-

采用透射电子显微镜(JEM-1200EX)观察CNC的形貌。用滴管吸取1滴待测CNC悬浮液,滴在电镜铜网上,用体积分数为2%醋酸双氧铀染色,干燥2 min后进行观察并拍摄图像。再使用ImageJ软件处理图像,统计CNC悬浮液微粒的长度与宽度,最终得出长径比分布。

-

使用偏光显微镜(Nikon ECLIPSE LV100ND)拍摄液晶薄膜的显微照片。用裁刀剪取少许CNC液晶薄膜,置于载玻片上,随后将载玻片放置在POM上观察。

-

采用紫外可见分光光度计(UV2400)对所制备液晶薄膜的λmax进行测试,波长范围为200~800 nm。

-

采用冷场发射扫描电子显微镜(SU8010)观察所制得液晶薄膜截面的微观结构。通过液氮淬断的方法制备薄膜样品横截面,并将其安装在样品支架上,成像前样品需喷金45~60 s,电子加速电压为5 kV。

-

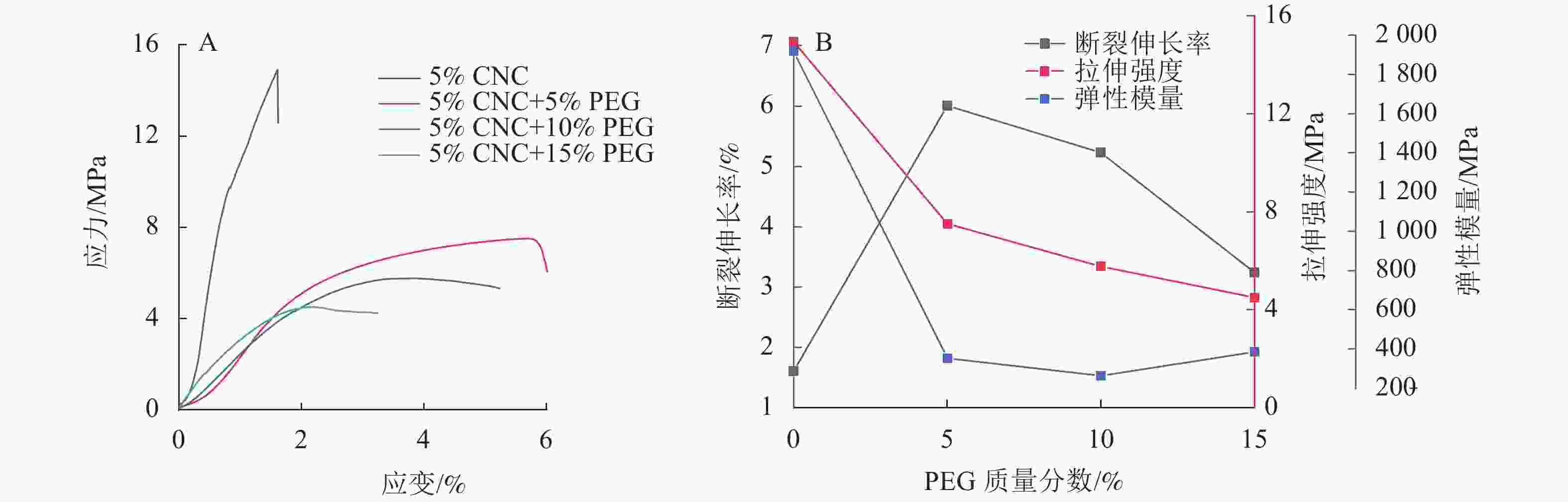

采用微机控制电子万能试验机(CMT6104)表征添加不同质量分数的PEG的CNC液晶薄膜的拉伸性能。将样品薄膜剪裁成长度约25 mm,宽度约5 mm的样条,安装样条于试验机上,以2 mm·min−1拉伸速率测试,测定样条断裂时的拉伸强度、弹性模量和断裂伸长率等。

-

在密闭空间中,过饱和盐溶液可以调控环境相对湿度。采用饱和LiCl、MgCl2、NaBr和NaCl溶液分别调控环境相对湿度为20%、40%、60%与80%。①湿度响应时间。将样品薄膜剪裁成样条状,分别放置于不同相对湿度的密闭环境中,每隔一段时间,采用紫外可见分光光度计测定其λmax,得出达到平衡状态下的λmax及所需时间。②吸湿-解湿响应行为研究。将样品薄膜剪裁成样条状,放置于相对湿度为80%的密闭环境中2 h,采用紫外可见分光光度计测定其λmax;随后放入烘箱中干燥2 h,再次测定其λmax,多次重复此过程即可得到其循环性能。

-

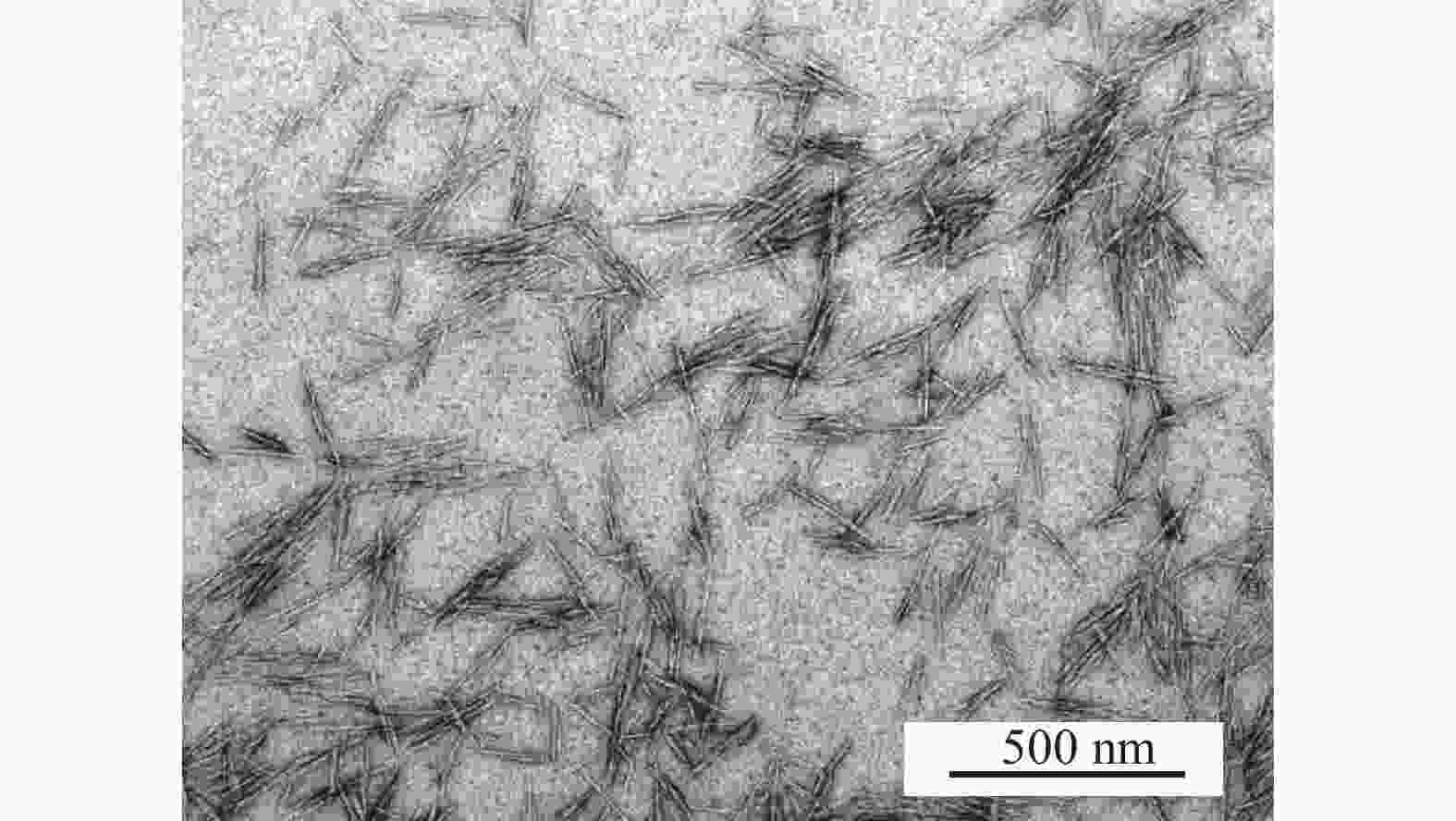

由图1可知:经过醋酸双氧铀染色后的CNC在TEM中呈现均匀的棒状结构,彼此之间排列松散,未出现明显的团聚现象,经统计:CNC的长度为(163.6 ± 60.0) nm,宽度为(8.6 ± 3.2) nm,长径比约19。

-

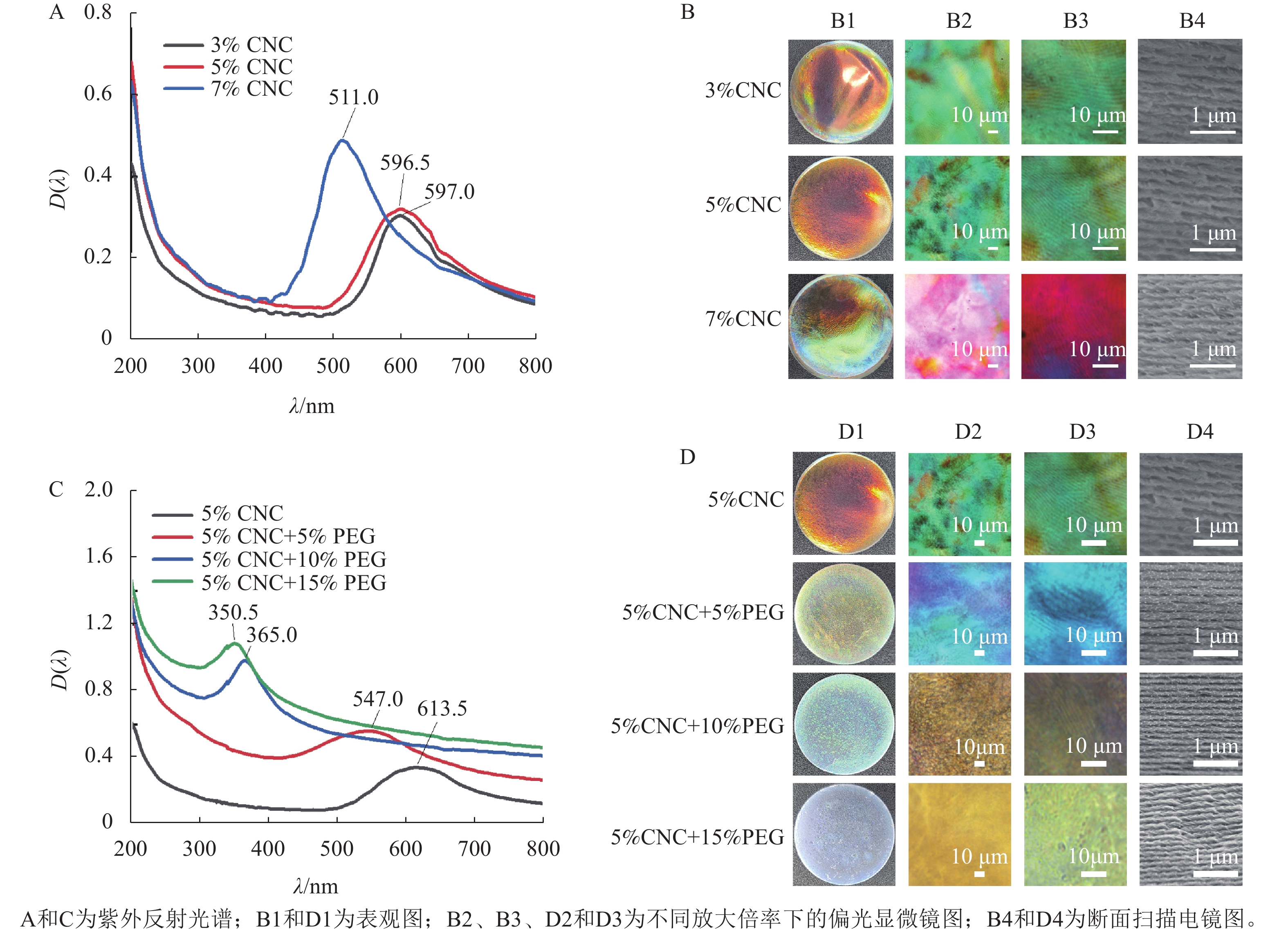

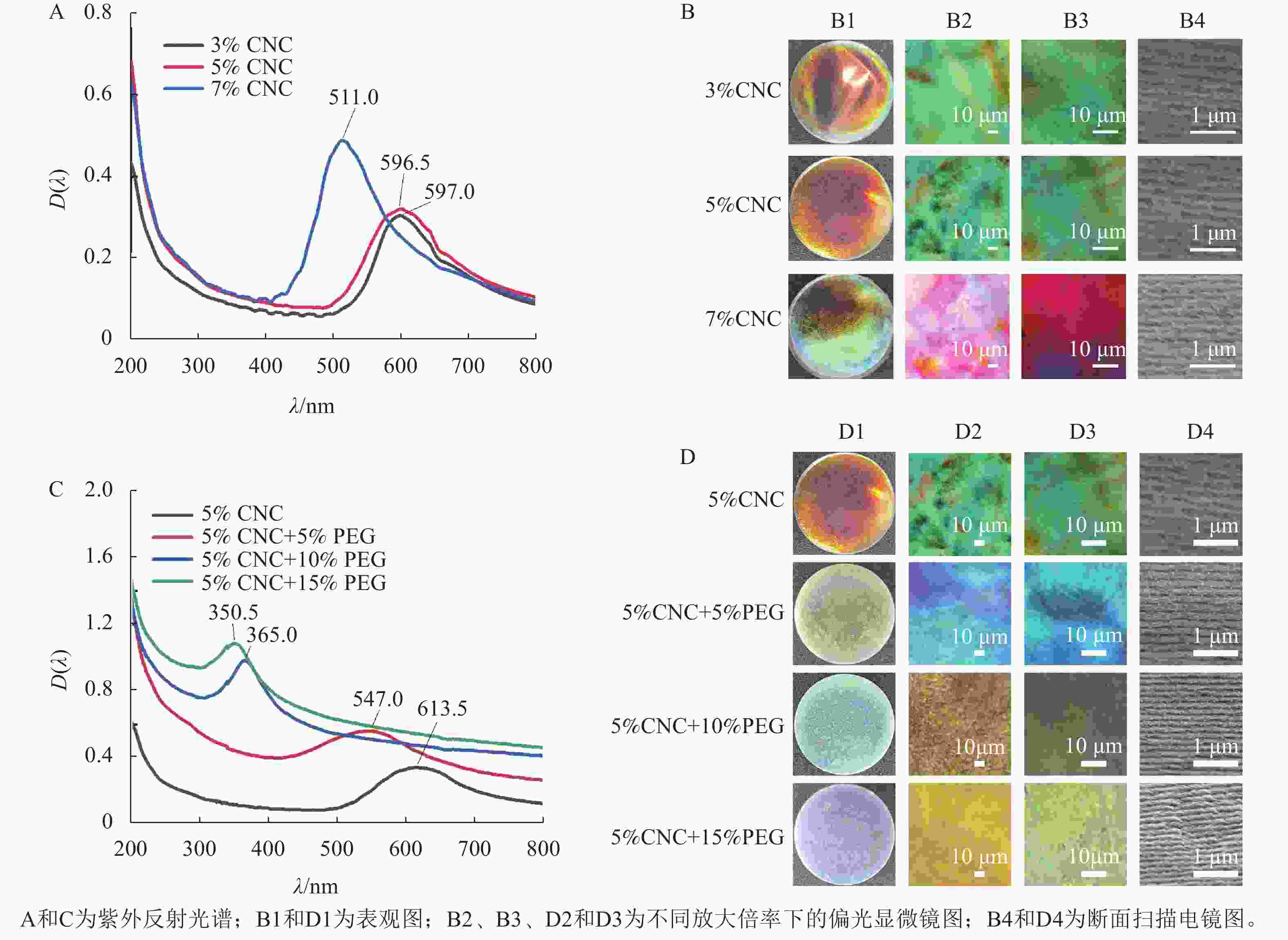

采用溶液浇筑的手段,可获得具有手性向列结构的虹彩色薄膜。由图2A和图2B1可知:所得薄膜都具有光滑表面及虹彩色,其中,3%CNC和5%CNC所得的薄膜颜色为橙红色,分别对应的λmax为596.5和597.0 nm,7%CNC所得的薄膜部分表现出蓝绿色,对应的λmax为511.0 nm。这是因为随着CNC质量分数的提高,CNC排列更加紧密,分子层间距离减小,从而导致螺距减小,λmax发生蓝移[19]。

由图2B2和B3观察到:3种不同质量分数的CNC薄膜都表现出显著的双折射特性,在高倍率下可以观察到手性向列相液晶特有的指纹织构。指纹织构出现的原因是CNC的螺旋轴与显微镜基片平行,观测到明暗相间的指纹状衍射条纹,形成了像指纹一样的织构图案[20]。图2B4为CNC液晶薄膜断面的SEM图,所有液晶薄膜都呈现出手性向列相液晶特有的层状螺旋结构,相邻层之间的距离是螺距的一半[21]。测量统计100段CNC液晶薄膜的螺距,3%CNC、5%CNC和7%CNC所得的螺距分别为401.0、394.0、335.0 nm。手性光子晶体的λmax与螺距(P)的关系可以用布拉格方程来描述[22]:$ {\lambda }_{\mathrm{m}\mathrm{a}\mathrm{x}}=nP\mathrm{sin}\theta $。其中,n为平均折射率,θ为反射光与平面夹角。以5%CNC液晶薄膜为例,n=1.52,θ=90°,因此λmax=599.0 nm,橙色的可见光波长范围为580.0~610.0 nm,液晶薄膜的颜色与之对应,这与UV-vis测得的λmax基本符合。

-

由图2C和图2D1可知:所有薄膜都具有光滑表面和均匀的虹彩色,随着PEG质量分数的增加,所制得的液晶薄膜的颜色由橙红色转变为黄绿色、蓝绿色,最后变为蓝紫色,复合薄膜的λmax从613.5 nm下降到350.5 nm,这是由于PEG分子中含有大量的羟基,羟基之间会形成氢键,进而形成微交联结构,使CNC分子层间距离减小,导致螺距减小,λmax发生显著蓝移[23]。与纯CNC液晶薄膜相比,PEG/CNC复合薄膜的颜色更均匀。

由图2D2和D3可见:与纯CNC液晶薄膜相同,复合薄膜也表现出双折射特性,且能观察到手性向列相指纹织构;由图2D4可见:与纯CNC液晶薄膜相同,所有液晶薄膜都能呈现出手性向列相液晶特有的层状螺旋结构。POM和SEM的结果都表明:PEG的加入保留了CNC的手性向列相特征。测量统计100段PEG/CNC液晶薄膜的螺距,PEG质量分数为0、5%、10%和15%的液晶薄膜螺距分别为394.0、361.0、263.0、244.0 nm。以PEG质量分数为5%的CNC液晶薄膜为例,n=1.52,θ=90°,因此λmax=549.0 nm,而黄绿色的可见光波长范围为540.0~570.0 nm,液晶薄膜的颜色与之对应,这与UV-vis测得的λmax基本符合。

-

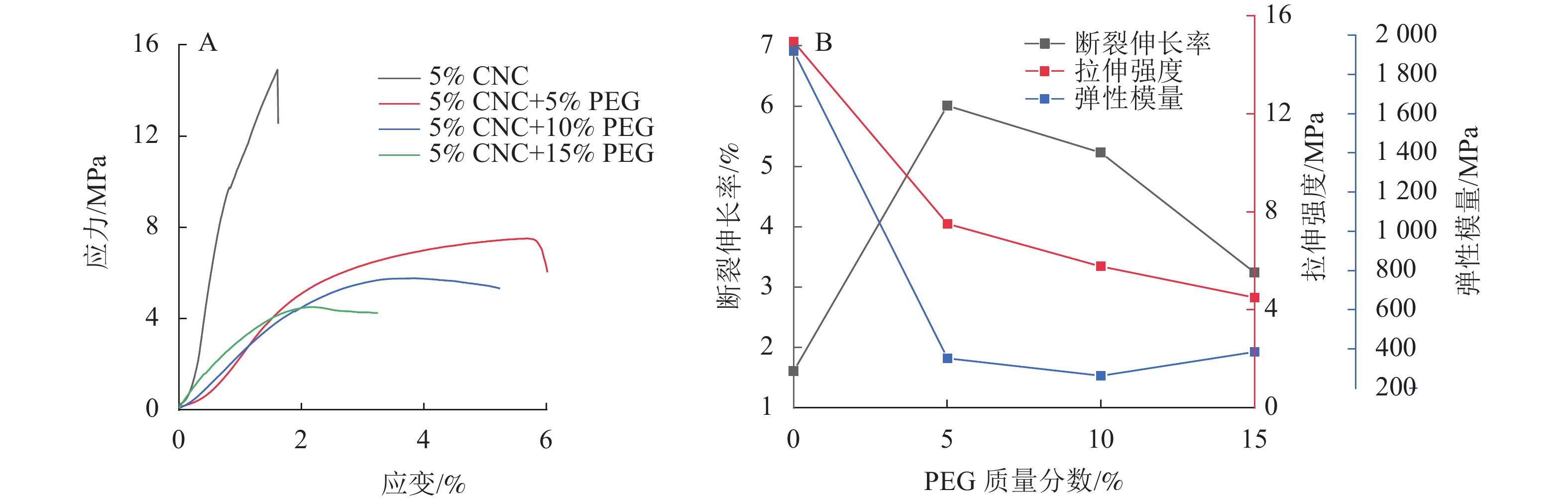

由图3可见:5%CNC液晶薄膜的断裂伸长率为1.60%,添加PEG显著提升CNC液晶薄膜断裂伸长率,5%CNC+5%PEG液晶薄膜的断裂伸长率为6.00%,对应力-应变曲线进行积分可得断裂能,断裂能为31.9 J·m−2,较纯CNC薄膜提升了138%,这主要是由于PEG能与CNC形成氢键,构成三维网络结构,进而提高薄膜的韧性[24]。然而,随着PEG质量分数的增加,CNC液晶薄膜的断裂伸长率会有所下降,5%CNC+15%PEG断裂伸长率下降到3.20%,断裂能较5%CNC+5%PEG 降低了65.4%,这是由于过量加入PEG在一定程度上破坏了复合薄膜的手性向列结构[25]。虽然PEG提升了CNC复合薄膜韧性,但使其拉伸强度及弹性模量下降,5%CNC+5%PEG 薄膜的拉伸强度下降了49.7 %,弹性模量下降了81.6%。

-

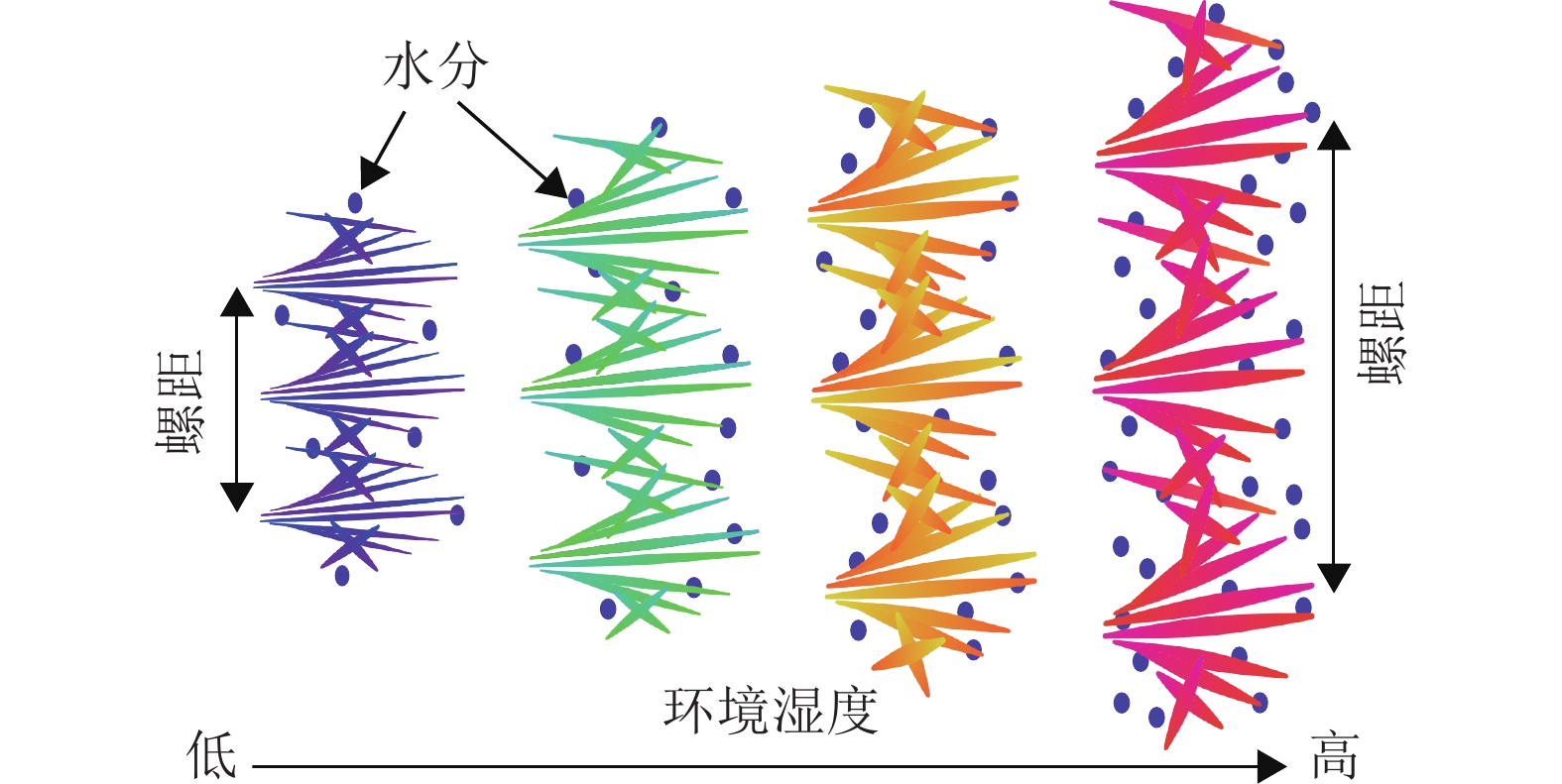

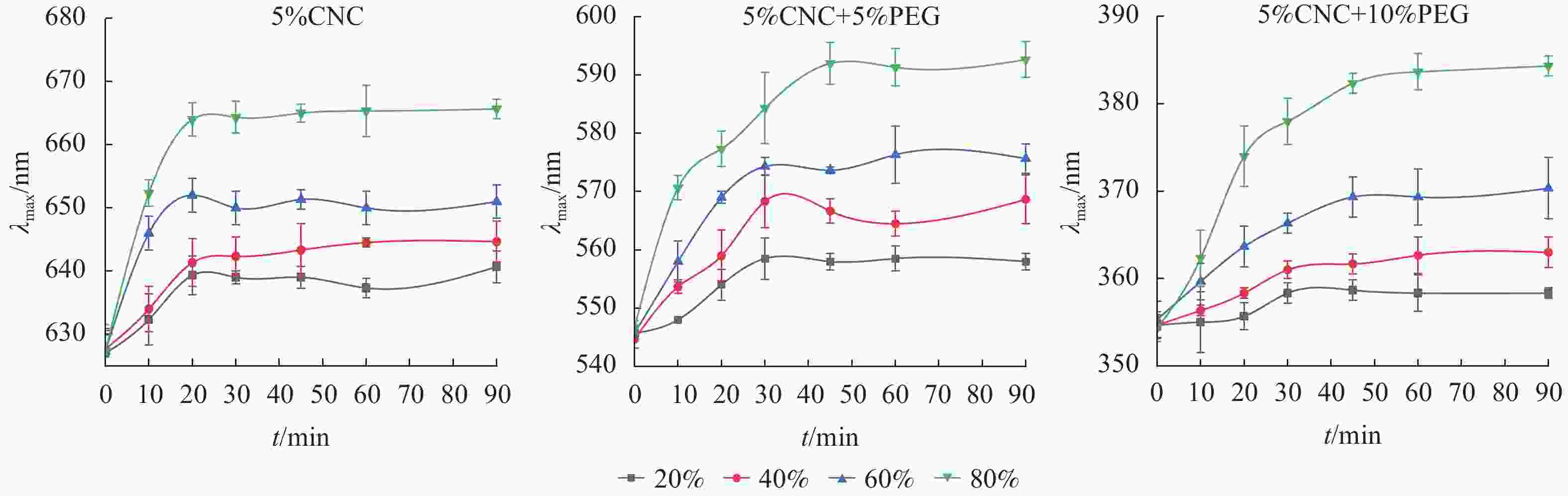

由图4可知:在所有环境湿度下,随时间增加,薄膜的λmax会发生红移,到达一定时间后,λmax恒定,因此,可以估算PEG/CNC液晶薄膜的湿度响应时间。此外,对于同一个PEG/CNC液晶薄膜,环境相对湿度越大,λmax红移程度就越明显,这是随着环境相对湿度提高,进入PEG/CNC液晶薄膜的水汽增多所致[13],也表明PEG/CNC液晶薄膜具有优异的湿度响应性。图5显示:PEG/CNC液晶薄膜纤维素表面存在大量的羟基,当环境湿度增加,水汽进入CNC液晶薄膜,使单个CNC分子之间的距离增大,螺距增大,λmax出现了红移[23]。

Figure 4. Changes of λmax over time of PEG/CNC liquid crystal films in different humidity environments

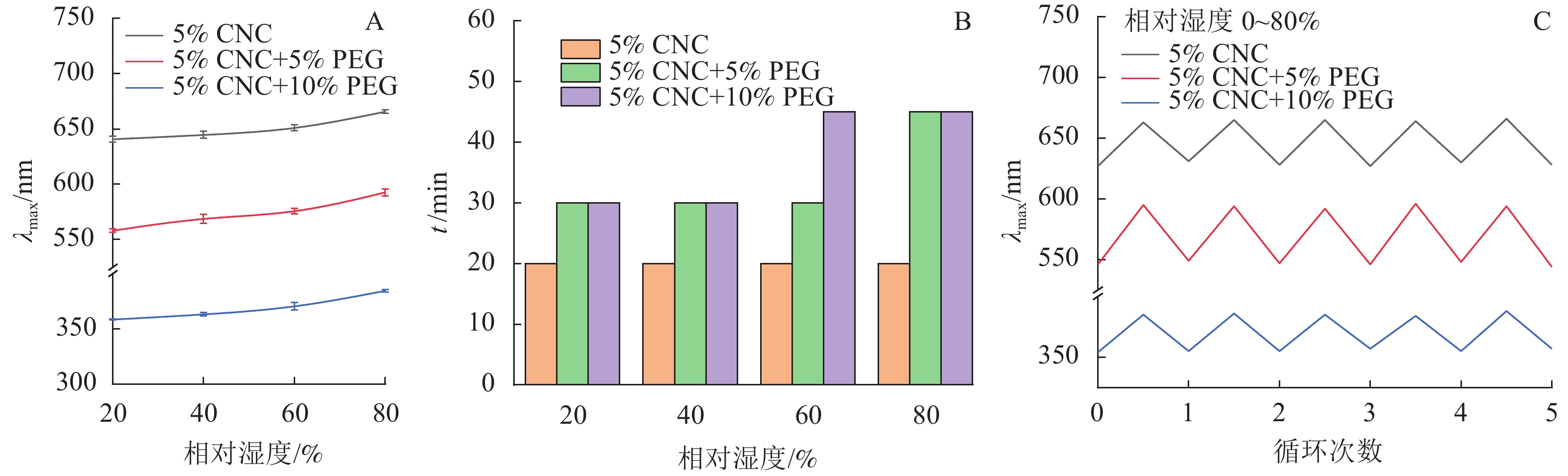

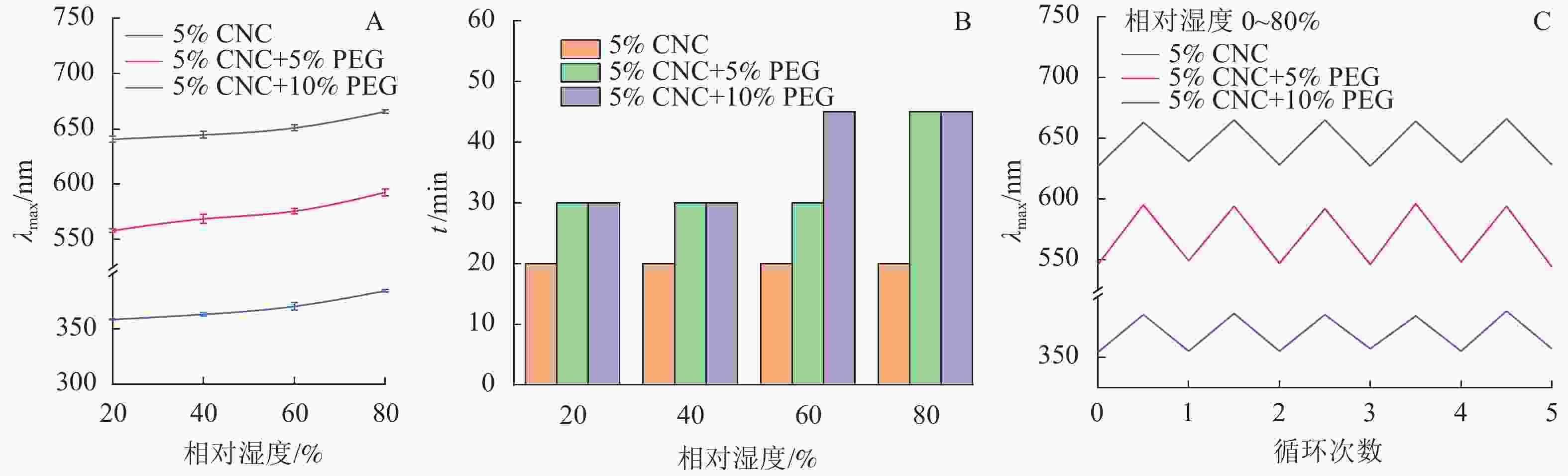

由图6A可知,随着PEG质量分数的提高,薄膜的λmax发生蓝移,这与2.3.1中的研究结果相一致。所有种类的薄膜均随环境湿度的提高而发生红移,说明其具有湿度响应性能。由图6B可知:随着PEG质量分数和湿度的增加,平衡时间增加,这是因为PEG/CNC液晶薄膜的湿度响应来自于CNC螺距的变化,PEG的加入限制了CNC分子的运动,因此需要更多的时间才能观察到平衡;同时周围环境的相对湿度越高,PEG/CNC液晶薄膜达到平衡波长所需要的时间也越长,这是由于薄膜需要吸收更多的水汽达到平衡所致。

Figure 6. λmax variation (A) and time for PEG/CNC liquid crystal films to reach the equilibrium wavelength (B) in different humidity environments, and humidity response (C)

随着环境相对湿度的提高,水汽能够进入CNC液晶薄膜中,λmax发生红移;在干燥过程中,进入CNC液晶薄膜的水汽又重新蒸发出来,λmax回复到原始状态[23]。由图6C可知,CNC和PEG/CNC液晶薄膜经过5次反复吸湿-解湿实验,均表现出良好的湿度响应重复性,平衡波长的变化率小于0.6%,说明其湿度响应性能很稳定。

-

本研究将木质CNC与PEG共组装,制备了一种对湿度具有敏感响应的虹彩色光子液晶薄膜。PEG可以调控复合薄膜螺距,从而起到调节结构色的作用。随着PEG质量分数的增加,复合薄膜螺距减小,结构色发生蓝移。PEG还可以提高复合薄膜的韧性,当PEG质量分数为5%时,所制得的液晶薄膜具有最大的断裂伸长率及韧性,断裂能提高了138%。PEG/CNC液晶薄膜具有良好的湿度响应性能,随环境相对湿度变化,复合薄膜的颜色相应改变,其中PEG质量分数为5%的复合薄膜的颜色变化最显著,λmax由545.0 nm变为595.0 nm。另外,随着PEG质量分数的增加,复合薄膜对湿度的响应时间增加,但不影响吸湿-解湿重复响应行为,因此,这种基于木质CNC的低成本响应光子材料在湿度监测领域具有重要的潜在应用。

Microstructure and humidity response of polyethylene glycol/cellulose nanocrystal composite liquid crystal films

doi: 10.11833/j.issn.2095-0756.20230236

- Received Date: 2023-04-10

- Accepted Date: 2023-07-05

- Rev Recd Date: 2023-07-03

- Available Online: 2024-01-19

- Publish Date: 2024-02-20

-

Key words:

- cellulose nanocrystals /

- chiral nematic structure /

- self-assembly /

- liquid crystal film /

- humidity response

Abstract:

| Citation: | XU Yunzhe, CHEN Yifan, LIN Xinyi, et al. Microstructure and humidity response of polyethylene glycol/cellulose nanocrystal composite liquid crystal films[J]. Journal of Zhejiang A&F University, 2024, 41(1): 169-175. DOI: 10.11833/j.issn.2095-0756.20230236 |

DownLoad:

DownLoad: